Computer numerical control (CNC) machining is a manufacturing process in which computers and software control how the machines manufacture parts. Special CNC programs instruct different types of CNC machines on which motions to make for a desired shape, choosing the right tool, the speeds and feeds of the tooling, turning coolant on or off, and various other commands.

The computer language for programming CNC machines is a standardized language called “G-code.” Visual programming tools called computer-aided manufacturing (CAM) software create the G-code. CNC machining is the method of choice when quality and precision are critical, parts and components are particularly complex, and repeatability is essential over long production runs.

What is a CNC Machine?

Before the technology that created computer-controlled machine tools was available, machinists used manually-controlled machines. Operators used handwheels and power feeds to direct the machining process along the X, Y, or Z-axis.

On the other hand, a computer controls servos operating the CNC machine and guiding it through the machining process. CNC machine tools allow for higher productivity because the machinery runs automatically without the attention of a full-time operator. Today, CNC machining is the dominant force in machining, while manual machines play a secondary role in lower-quantity work, repairs, and prototyping.

In the past, CNC machines were strictly in the industrial domain since their costs were out of reach for most one-person shops and hobbyists. However, there are now CNC machines for almost any budget, and DIYers are jumping on the bandwagon and buying them for their home shop.

Here are 12 of the most common types of CNC machines. Each performs somewhat different machining operations with few human errors, high-speed processes, and high-quality results.

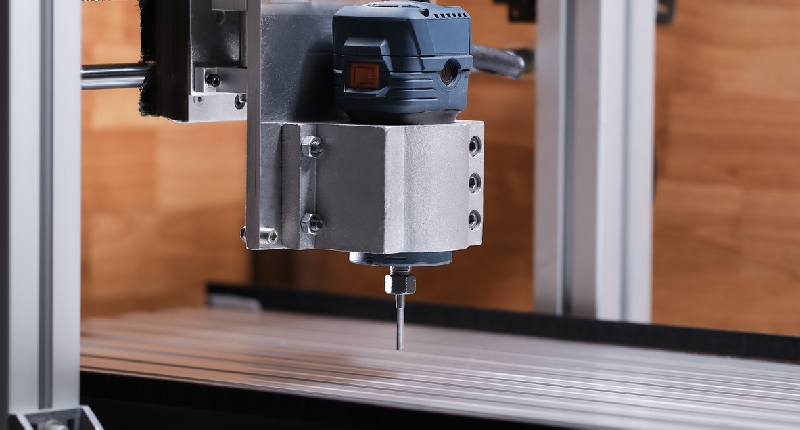

1. CNC Milling Machine

CNC milling machines use rotating cutting tools to remove material from a workpiece. The primary 3-axis CNC machines move along an X-axis (side to side), Y-axis (in and out), and Z-axis (up and down). These “mills” have been the backbone of machine shops and factories for many years and are used in manufacturing industries such as automotive, aerospace, medical, military, oil and gas, and precision engineering sectors where holding tight tolerances are required.

Sometimes referred to as CNC machining centers, the more advanced CNC machine tools can operate along up to twelve axes. These machines often have automatic tool changers, advanced machine coolant systems, pallet changers, and the latest software to improve the efficiency and accuracy of their machining processes.

2. CNC Lathe Machine

CNC turning mostly produces cylindrical parts by rotating a workpiece on a spindle and removing material with fixed cutting tools and drill bits. CNC lathe machines can be programmed to create various details on the rotating piece, making them the machine of choice for producing round parts, especially in large quantities where consistency, precision, and high production rates are paramount.

Although there are two types of CNC lathes, the horizontal style is the most popular. CNC horizontal lathe machining turns shafts, drums, and round parts. Depending on the length of the workpieces to be machined, these lathes can take up quite a bit of floor space.

On the other hand, CNC vertical lathes rotate the workpiece upright, allowing the spindle to cut at hard-to-reach angles. Vertical lathes have a smaller footprint and are ideal for turning larger, heavier workpieces.

3. CNC Router Machine

CNC routers can machine complex shapes from soft materials like wood, plastic, composites, and aluminum. These machines are limited to relatively thin materials, like plywood boards or sheet metal since their cutting tools have limited motion along the Z-axis. This limitation contrasts with CNC milling machines with an extended range of motion. However, like CNC mills, CNC routers use G-code to automatically move a high-speed rotating cutting tool to various coordinates to remove material from a workpiece.

CNC routers typically use a gantry-style construction with the spindle traveling left and right along the X-axis and back and forth on the Y-axis. Still, they are designed for something other than cutting complex harder metals, such as stainless steel. Instead, softer materials work better on gantry-style CNC routers since they are less ruggedly built than standard CNC mills.

4. CNC Electrical Discharge Machine (EDM)

CNC electrical discharge machines, or EDM, use a “non-contact” process that effectively machines parts despite their hardness. EDM involves placing an electrode or wire and electrically conductive materials into a circulating dielectric fluid. The fluid acts as an insulator until a specific spark gap and voltage ionize it, enabling a spark to travel to the workpiece.

Using CNC control, the electrode or wire moves as directed, rapidly turning the current on and off, helping to flush the material (swarf) from the workpiece.

There are two main types of EDM machines: sinker EDM and wire EDM machines.

Sinker EDMs use a copper or graphite electrode to create the shape, with the electrode machined to a mirrored image of the finished form in the workpiece. These electrodes can produce up to 30,000 electric sparks per second as they burn the shape.

Wire EDM feeds a strand of wire from a spool to the workpiece using a wire drive system. Electrical contacts energize the wire and pass through the workpiece at a feed rate determined by the material thickness and other factors.

Deionized water surrounds the wire, and electric sparks are continuously emitted along the length of the wire. Rollers pinch the wire and provide tension while guides above and below the workpiece position the wire on its path. The EDM wires typically have diameters of 0.010” to 0.012” with thinner wires at 0.001” to 0.004”.

5. CNC Plasma Cutting Machine

CNC plasma cutting is another method for slicing through metals with a plasma torch controlled by a computer program. Plasma cutters force gas or compressed air at high speeds through a nozzle. After an electric arc is added to the gas, ionized gas (plasma) is formed and cuts through the metal.

CNC plasma cutters are available in various sizes and prices, all able to cut through metal accurately and at speeds up to 500 inches per minute. Plasma cutters require a plasma gas and an assist gas to function, determined by the type of metal being cut.

6. CNC Grinding Machines

The term CNC grinding machine covers a significant territory, with cylindrical grinders, surface grinders, and centerless grinders covering most of it. CNC grinders automatically remove material using grinding wheels to improve surface finishes and meet tolerances that may not be possible through standard tooling on milling machines and lathes.

Cylindrical grinding machines consist of a spindle head that holds and rotates the workpiece while the grinding wheel moves across its surface, making various configurations such as tapers, steps, chamfers, grooves, and finished sizes on the outside or inside diameter of the workpiece.

Surface grinders generally work on flat surfaces to create the smoothest surface finishes possible or to ensure the accuracy and flatness of critical dimensions—sometimes both.

In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds. One grinding wheel is on a fixed axis and turns so that the force applied to the workpiece is directed downward. The centerless grinding processes allow parts to be held to tighter dimensional tolerances, achieve smoother surface finishes, and have high degrees of straightness.

7. CNC Laser Cutting Machine

Laser cutting is a fabrication process using a focused, high-powered laser beam to cut the material into various shapes. The material’s melting, vaporizing, and burning occur after focusing the laser beam. The CNC laser cutter is appropriate for multiple materials, including metal, plastic, wood, and glass, and can produce precise and complex parts without special tooling.

There are several types of laser cutting, including oxidation, scribing, and fusion cutting. Each process makes parts with precision, accuracy, and high-quality edge finishes. There is less damage to the workpiece, less waste, and low power consumption with the laser cutting process.

8. CNC Drilling Machine

In simple terms, CNC drilling is a machining process mainly using drill bits to produce round holes in a stationary workpiece. The holes typically accommodate machine screws or bolts for assembly, so tolerances are not as tight as in other machining operations.

The CNC drilling process follows many steps as other CNC machining operations, including using CAD and CAM software, setting up the CNC machine and tooling, and assigning an operator to run and inspect the workpieces.

9. CNC Water Jet Cutters

A CNC water jet uses a high-pressure water system to cut various materials. Sometimes, water alone is sufficient to cut materials like wood and rubber. At other times, the water is mixed with an abrasive substance (like garnet or aluminum oxide) to cut more rigid materials.

The water jet operations are typically performed underwater to reduce the noise and mess from splashing. The water pressure is usually between 20,000 to 60,000 PSI, which is 30 times more pressure than a power washer, and it forces the water through a narrower nozzle of 0.010” to 0.015” in diameter.

Pumps and filters send the water into the CNC water jet unit. The filtering process is critical since only clean water can attain the ultra-high pressure required for a consistent cutting stream. Filtering also protects the unit’s parts, although sometimes a water treatment system is needed if the water contains harmful minerals.

10. 5-Axis CNC Machines

5-axis CNC machines allow a cutting tool to move in five different directions — X, Y, Z-axes, and A and B, which the tool rotates around. Programmers can approach a workpiece from all directions in one operation with these machining centers, eliminating the need to manually reposition the workpiece between processes.

Although 5-axis CNC machines are expensive upfront, they save time and allow manufacturers to create complex and precise parts that might otherwise be impossible. Many of the components in the medical, oil and gas, automotive, and aerospace industries fall into this category. There are a few 5-axis machines, including indexed 5-axis CNC machines, continuous 5-axis CNC machines, and mill-turning CNC centers.

The mill-turning CNC centers are similar to CNC-turning machines, with one notable difference: these machine tools can also perform CNC milling operations. By combining the elements of CNC lathe machines with milling capability, mill-turning CNC centers offer accuracy and versatility, making them ideal for creating parts such as camshafts or centrifugal compressors.

With indexed 5-axis CNC machines, the cutting tool moves along three axes and doesn’t maintain continuous contact with the workpiece. Still, the table and tool head automatically swivels in two directions between operations. Indexed 5-axis machining works well for producing housings, jigs, and fixtures, and it falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining for speed, precision, and handling complex geometries.

With continuous 5-axis CNC machining, the cutting tool and the workpiece rotate and move simultaneously during operation, saving time and allowing for complex geometries. Continuous 5-axis CNC machining offers a better surface finish, higher speed, and enhanced dimensional stability.

11. 3D Printers

3D printing is a type of additive manufacturing where a digital model is turned into a tangible, solid, three-dimensional object. The process involves laying down successive, thin layers of material. This process contrasts each subtractive manufacturing process listed above, during which material is removed from a larger block of material to produce a part, component, or product.

3D printing’s popularity has grown because it makes manufacturing accessible to more people than ever before. With starting prices of around $300 and space-saving sizes, 3D printers appeal to many hobbyists and entrepreneurs looking to start a small business.

However, even though 3D printing has benefits, it also has its share of drawbacks, including:

- Restricted build size: Small print chambers limit the scope of printed parts

- Post-processing: Most 3D printed parts require cleaning up to remove support material from the process and to smooth the surface to get the required finish

- Little savings on large volumes: 3D printing has a static cost, unlike conventional methods like CNC machining and injection molding, where large volumes may be more cost-effective to produce

- Part structure: 3D printed parts are produced layer-by-layer, and even though these layers adhere together, they could delaminate under specific stresses or orientations. The homogenous parts from CNC machining are a better option since they cannot separate or break.

In Summary

Today, manufacturing is all about speed, efficiency, and consistency. In this environment, automation will play an essential role in manufacturing activities. At the same time, modernized, data-driven tools and equipment like CNC lathes, milling machines, and the other CNC equipment mentioned in this article will drive innovation.

As a result of such high-paced activities, precision machined components will provide businesses with a competitive edge through complex designs that could not be reproduced profitably by any other manufacturing method. CNC machines are the gateway to the future with competitive prices and increasing profitability!