Although EDM (electrical discharge machining) is among the most recent metal processing methods, its earliest application began in the mid-1940s when it was used to remove broken taps and sheared-off bolts from valuable aluminum castings. Rapidly pulsing high-voltage electrical discharges (sparks) were passed across the gap between the electrode and the grounded workpiece, removing taps and bolts from the castings by erosion. Hardened taps were removed without force or extreme heat, leaving the castings unaffected.

On the heels of this simple drilling operation, the second element of EDM processing developed: ram EDM or sinker discharge machining. Essentially identical to EDM drilling, ram EDM added a complex form to the end of the “drill” electrode, allowing a finished and precise cavity shape to be “machined” in one action. A third EDM type soon followed. Wire-cut EDM uses a straight wire electrode to cut a vertical or angled slot, as the wire is slowly fed through the cut to maintain a new electrode at all times.

EDM in 2024

Manufacturers typically choose electrical discharge machining (EDM) when conventional machining methods cannot provide a solution. The EDM process uses thermal energy to burn away material from a workpiece to create the desired shape. Although it is not the most commonly used CNC machining process, engineers turn to EDM whenever hard materials and complex shapes are not conducive to traditional machining.

EDM does not require or employ mechanical force for material removal. Instead, it uses a rapid sequence of electrical current discharges between electrode materials submerged in a dielectric fluid. The electrodes (one being the workpiece) are separated by a spark gap generating extreme electrothermal heat in the spark gap zone. The heat vaporizes portions of the workpiece surface, a process called spark erosion.

Let’s look at the EDM process in detail to discover its two main types, where it’s used, and what benefits it offers:

What are the Two Main Types of EDM Machines?

The two main types of EDM machines are Ram EDM and Wire EDM.

How Does Ram EDM Work?

Ram goes by several names, including conventional EDM, die-sinking EDM, sinker EDM, spark-eroding EDM, and cavity-type EDM. But no matter what you call the process, it works like this: An electrical potential difference is created between the electrode and workpiece, electrically conductive materials, and submerged in a dielectric fluid such as deionized water.

In the Ram method, a graphite electrode (cutting tool) is machined into the mirror image of the desired shape and “sunk” into the workpiece on the end of a vertical ram. A sinker EDM machine uses electric spark erosion to remove the metal, creating the angles and contours of the part or cavity. The dielectric fluid acts as an insulator until the process reaches a sufficiently high voltage.

The dielectric oil also works like a coolant, removing heat from the piece to prevent excessive thermal expansion. As the oil cycles through a filter, it removes the metal particles and continues through a chiller that keeps the oil below its flash point.

Ram EDM electrode tools, like graphite or copper, must display high melting and vaporization temperatures or high thermal conductivity. The tool materials must also show the ease of fabrication and wear resistance. Cost is another consideration when choosing the material for a tool electrode.

The following are essential factors determining the suitability of a material as an electrode tool in EDM machining:

- Higher metal removal rate

- Lower tool wear

- High degree of electrical efficiency

Although any conductive material can be an electrode material, taking into account the factors and properties for better application in EDM, graphite has been the most popular tool material. It exhibits a relatively low wear rate with a higher degree of electrical efficiency and is inexpensive and easy to fabricate.

How Does Wire EDM Work?

Wire EDM machining is similar to ram EDM, but the electrode is an electrically charged thin wire that cuts the metal part into various shapes. Machining a workpiece using this process also involves submerging it into a dielectric fluid and moving the wire through it to produce sparks as it passes an electric current.

Wire burning produces small chips and high accuracy by melting or vaporizing the material—even hardened steel—instead of cutting it. This so-called wire erosion process slices through metal to create parts deemed unsuitable for conventional machining techniques, and it works well as long as the workpiece has conductivity.

Like ram EDM, wire-cut EDM is another example of non-contact spark machining, during which the wire does not touch the metal. When the wire and the workpiece close, a hot electric charge jumps the gap and melts tiny pieces of the metal.

The wire is continuously fed from a spool and held between upper and lower diamond guides. Since the automatic feeder constantly unspools new wire for use in the machining, as the old wire becomes dull, new wire is there to take its place, so the wire used in this process does not necessarily need to have strong resistance properties.

The guides move in the X-Y plane, but sometimes the upper guide can also move independently, allowing for transitioning shapes, such as circular on the bottom and square at the top. The wire electrode can be programmed to cut complex geometries with excellent surface finishes while holding tight tolerances.

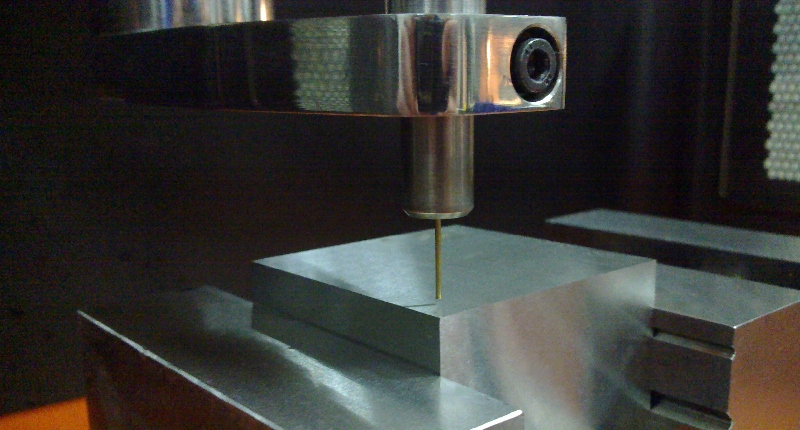

What is Small Hole Drilling EDM?

Although not used as often as wire and ram EDM, hole drill EDM machining is designed to drill small, deep holes with diameters as small as 0.065 mm and depths up to 1m (or 250 times the hole diameter). The electrode and the workpiece are connected to a power supply. After sufficient charge builds up on the electrode to create a high-temperature spark, the electrode vaporizes and erodes the workpiece in a localized area.

The electrode is hollow, allowing dielectric fluid to pass through it, and along with the rotation of the electrode, stabilizes the EDM process and helps remove the workpiece debris. The spark erodes the material as the electrode is rotated and moved down until the hole is complete.

What are the Applications of EDM Machining?

Because they are high-precision machine tools, wire EDM machines are top-rated in the automotive, medical, and aerospace industries. However, they help make prototypes or for full production runs and are often employed in the manufacturing industry for metal components and tools. The EDM process is favored for applications requiring low levels of residual stress.

Here are the three leading industries of EDM machining:

Automotive Industry

The automotive industry requires a manufacturing process for parts with complex shapes using hard materials. Because of this, they favor using wire EDM machines because the process does not rely on mechanical forces that lead to tool wear, and the wire electrode does not need to be stronger than the workpiece. The process works well for making holes and cavities for parts like bumpers, dashboards, and car doors.

Medical Industry

EDM machines produce accurate parts in all medical fields, including optometry and dentistry. They are used to manufacture medical equipment parts and components and medical and dental implants and syringe components without affecting their structural integrity.

Aerospace Industry

Wire EDM produces close-tolerance parts for aerospace part manufacturers. This process benefits parts unable to withstand the high temperature and stress associated with traditional cutting tools. For example, many of these components—engines, turbine blades, and landing gear parts—require accuracy and an excellent surface finish.

Applications Specific to Ram EDM

Ram EDM can create complex cavities, making it particularly useful for fabricating molds, dies, and other types of tooling made from hard materials such as tungsten, carbide, and tool steel. It also works better than conventional machining processes for creating sharp inside corners and deep ribs.

Common ram EDM applications include:

- Dies

- Plastic injection molds

- Deep and thin ribs

- Blind cavities

- Rapid tooling

- Sharp inside corners

- Blind keyways

- Internal splines

- Threads

Is EDM a CNC machine?

An EDM machine is one of several CNC machines like CNC mills, lathes, and routers. Programming a wire EDM, for instance, is much like a two-dimensional milling machine, and the program can start away from the workpiece or in the middle inside a pre-drilled hole. Wire EDMs require an NC G-code program for the geometry, as found in milling (G90, G91, G00, G01, G02, G03).

The differences are in the M-code commands. Wire EDMs have many specialty M-codes specific to wire EDM operations. The most effective method for wire EDM programming is a dedicated software module designed for wire EDM operations. This specialty software provides time-saving processing tools that will not be found in software designed for milling.

What Materials Can Be Machined by EDM?

Any conductive material, including stainless steel, titanium, tungsten, carbide, aluminum, brass, alloys, and superalloys, can be cut using the EDM machining method. Because of its accuracy and capabilities on hardened steel, EDM, specifically the wire-cut technique, has become a popular cutting method in all industries.

What are the Benefits of EDM Machining?

One primary advantage of the EDM process is that the tool electrode (wire or graphite) never touches the workpiece, meaning that it never stresses the part. For example, medical device manufacturers can use EDM to add slots, grooves, and eyelets in machined parts while applying minimal stress.

Another plus of EDM is its high-quality surface finish. The EDM process creates smooth surfaces without burrs while holding tight tolerances. For instance, wire EDM can build very thin eyelets and through-slots in medical devices, which cannot be machined using conventional machining centers.

Other advantages of the EDM method include:

- Manufacturers can use EDM successfully on heat-treated or any hard materials

- An excellent surface finish, up to 0.2 microns, can be achieved

- Because the tool and work do not have contact, mechanical stresses are not developed

- Complex shapes can be reproduced

- Highly accurate

- Economical

- Machining time is not significantly more than the traditional machining process.

- The tool life is extended because of proper lubrication and cooling

- Hard surfaces that are also resistant to erosion can be developed easily on the dies

- EDM works on any material that is electrically conductive

What are the Limits (Disadvantages) of EDM?

The EDM process removes material with electrical charges, which means it’s limited to electronically conductive workpieces and will not work on composite or dielectric materials. Wire EDM cutting may create an oxide layer on the surface of specific metals, so it must be cleaned to maintain optimal quality.

Electric discharge machining is challenged by parts and components that can only be held firmly without compromising the shape. For example, tubular-shaped parts risk being deformed while secured for EDM cutting, causing quality issues.

Other disadvantages of EDM machining include:

- Slower machining times

- Excessive electrode tool wear

- Reproduction of sharp corners might not always be possible

- Metallurgical properties of the material could change from the high heat

- Deep-hole electrodes often need redressing

- Experienced EDM operators are hard to find

- EDM machines consume high amounts of power

In Summary

A quick comparison of sinker EDM and wire EDM reveals their differences:

Sinker EDM uses a graphite electrode tool with a shape machined on the end that is “sunk” into the workpiece. The movement of this method is mainly along the Z-axis. The dielectric liquid in which the operation occurs is typically hydrocarbon oil. The process is predominately used in mold making.

On the other hand, wire EDM has thin brass wire as its electrode to cut into the workpiece from the side. The movement in this method is along the X and Y axes, and its dielectric liquid is usually deionized water. Wire EDM has numerous applications, with punches, tooling, and dies being high on the list.

As with other CNC machine tools, EDM machines are becoming more intelligent, resulting in devices requiring little or no attention. Most of these changes focus on making the equipment easier to operate or run without an operator.

As things stand now, EDM machining offers various benefits such as high accuracy, good surface finish, and the capability to machine hardened material. However, EDM machining has a few disadvantages, such as slower machining times, that must be addressed when applying EDM machining.