3-in-1 3D printers have risen in popularity because of their unique versatility. You can do 3D printing with its print head, CNC carving using standard CNC machine tooling, and laser engraving all in one machine. This flexibility appeals to DIY users, hobbyists, and beginners who can be exceptionally creative without purchasing multiple machines.

The Snapmaker Original was the first model in the category of multi-purpose machines, and the Snapmaker 2.0 Modular continued that popularity by addressing the issues of its predecessor. Many still consider it the best 3D printer combo device.

Although the Snapmaker has several excellent features and is a high-quality machine, it’s not the only one in the market. We have assembled a list of 11 features you should consider when shopping for a 3D printer/laser cutter/CNC router combo machine. We’ll highlight each critical component to help you decide which 3-in-1 3D printer matches your needs.

How Does a 3D Printer Work?

Most machinists and tool-and-diemakers learned their trades in “subtractive” machining. In other words, they took a block of metal and cut away the excess material to reveal the part or component inside using a machine tool such as a milling machine or lathe.

3D printers don’t work like that. 3D printing is an “additive” process during which the printer extrudes molten plastic through a tiny nozzle moving precisely under a computer’s control. Working automatically, it builds up a 3D model one layer at a time, starting at the bottom, by repeatedly printing over the same area in fused depositional modeling (FDM). The results of this process are 3D printed parts instead of machined parts.

What Are The Advantages of a 3d Printer Laser?

You might ask: If I do rapid prototyping, I can turn to 3D printing, CNC carving, or laser cutting for prototypes or end-use products and components. So, what are the benefits of having these three technologies in a single machine?

Saving money

An all-in-one 3D printer is more cost-efficient than buying three separate machines. You’ll save money on the initial equipment costs. Your operating expenses will decrease since you won’t be hosting three individual devices and the multiple filters, power outlets, and enclosures they will require.

Even though you might only occasionally need one of the modules (the laser module, for instance), it is less expensive than buying a separate machine or outsourcing the work. This benefits small shops, educational institutions, hobbyists, or those on a tight budget who cannot afford different devices for each process.

Saving space

3-in-1 3D printers utilize your limited workshop, workbench, or desktop space more effectively because they combine all three functions in one machine, leaving more room for other production machines.

Operating ease

Although some 3-in-1 3D printers are challenging to learn and operate, most devices have been designed to be easy to use. Their features are straightforward to configure in the software and require a minimum of technical knowledge.

Also, moving between the machining modules is typically quick and effortless, allowing even those unfamiliar with CNC milling and laser engraving to be up and running quickly.

Look for These Features in a 3-in-One 3D Printer

1. Durable Build

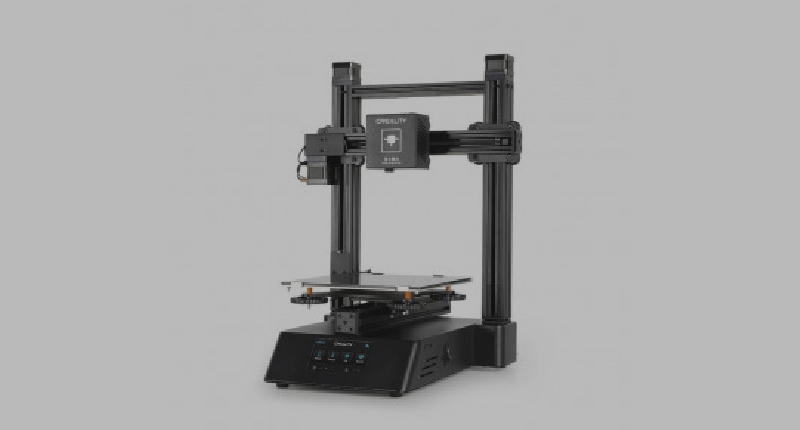

Models like the Creality Ender 3 are built with an industrial-grade aluminum frame, ensuring that the 3-in-1 unit is a sturdy and stable device capable of producing accurate printed parts, CNC models, and laser engravings. In other words, more sturdiness translates into stability and enhanced precision. Some Creality models have an automatic bed leveling (sometimes called auto leveling) feature.

2. Substantial Build Volume

It would be best to determine the sizes of the pieces you will create with your 3D printer combination. For instance, the Creality CP-01 model has a maximum build volume of 200mm x 200mm x 200mm, while the Snapmaker Artisan can provide a more significant build volume of 400 x 400 x 400 mm.

3. Full Enclosure

Many 3D printers are not enclosed, but the added safety of a full enclosure will offer peace of mind.

4. Automatic Calibration

With specific models like the ZMorph Fab, you don’t have to perform calibrations or configurations since the machine automatically detects the tool you have attached automatically and re-calibrates the entire machine. This feature kicks in, whether it’s immediately after you have unboxed the printer, changed the tool, or started planning a new project.

5. Large Touchscreen

The Snapmaker Artisan is one of several 3-in-ones with a 7-inch touchscreen and the rest of the machine’s electronics. It provides a cleaner look and separates the electronics from the printer’s hardware.

6. Reduced Noise Levels

Here’s a feature that might save your nerves after a long day on the job: reduced noise levels. Typically, all those moving parts on a 3D printer can generate plenty of noise. The ZMorph Fab is one of the printers generating such a low noise level that it’s possible to work next to it and think simultaneously.

7. Power Panic Feature

Power outages can ruin your printed part, so look for a printer with a PSU protection feature that resumes the print after a power outage. When the power returns, tap the “Yes” button when the printer’s screen asks you if you want to resume the print. It will continue where it stopped, so you never have to worry about long-running prints being ruined by an outage or someone accidentally pulling out the power cord.

8. Multi-Material Printing

A dual-extrusion 3D printer tool head enables multiple colors and multi-material printing simultaneously. Most machines support any 1.75 mm filament type, including PLA, ABS, PETG, and flexible filaments like TPU.

9. Handheld Pendant Control

The Diabase H-Series printers offer pendant control, bringing several benefits compared to a touchscreen. For instance, the pendant control offers you full tactile feedback from its scroll wheel as you use it, and you can detect whenever a command has been sent to the machine.

10. Accurate Laser Engraving

The 3D laser unit of some combos is exact and capable of engraving with only minor deviation. Accuracy is one of the primary issues that laser engravers face, but the Creality CP-01 has managed to avoid it.

Although the machine has a default laser engraver head, that doesn’t mean you can’t replace it with something more powerful. For instance, the xTool D1 Pro 20W laser engraver is considered one of the most powerful diode laser engravers. Remember, a more powerful laser engraver allows you to work with more challenging materials requiring a higher processing temperature.

11. Upgrade, Repair, and Maintain Easily with Modules

3-in-one 3D printers have two main components: the extruder and the milling head. Although it’s a complex piece of machinery, the modular style of these machines makes them easy to replace, repair, upgrade, and maintain, even without significant experience. Choosing a modular device that will be easy to service could save you future frustration.

What Is The Difference Between a 3D Printer and a Laser Cutter?

A 3D printer uses an additive process where a computer-controlled printer extrudes molten plastic through a small nozzle to build 3D objects one layer at a time. On the other hand, a laser cutter uses a laser to cut or engrave materials like wood, acrylic, leather, and metal. The computer controls the laser beam precisely to cut or engrave the material according to a design file. This process is called subtractive manufacturing because it takes away material from a bigger piece until it reaches the final shape.

How Much Do 3-in-One 3D Printers Cost?

Here is a sampling of the prices on 3D printer combos:

- Snapmaker 2.0 Modular 3-in-1 3D Printer A350T/A250T with One Black PLA Filament: $1299.00 Amazon

- Snapmaker Artisan 3-in-1 3D Printer with 10W Laser and Enclosure: $2949.00 Snapmaker

- ZMorph Fab Multi-Tool 3D Printer: $2,599.00 MatterHackers

Final Thoughts

Because 3-in-1 printers are relatively expensive, you want to have the best value for your money. The Snapmaker 2.0 and the ZMorph Fab models allow more customization and picking the specs you want without overpaying. The Snapmaker Artisan offers the most build volume and work area, regardless of which module you’re using.

The Snapmaker Artisan or Snapmaker 2.0 are two of the best 3D printers for laser engraving since both printers can use Snapmaker’s 10W high-power laser engraver module. These printers also allow for quality 3D printing, and the Artisan has dual extrusion capabilities.

The best 3D printer CNC attachment belongs to the ZMorph Fab. Cutting at a rate of 120mm/s, with 300W power and a max depth of 0.5mm, the ZMorph 3D printer CNC module is powerful enough to work with various kinds of wood, some acrylics, and stones.