CNC Milling Machines

A top-tier CNC milling machine offers a host of advantages, from its ability to maintain a compact footprint to its precise control over machining operations. CNC Masters offers a lineup of CNC milling machines that cater to the needs of both small businesses and enterprises, combining ample power with affordability.

Showing all 4 results

When it comes to versatility and precision, few machine tools can rival the capabilities of CNC milling machines.

CNC Milling Machines For Everyone

Atop-notch CNC milling machine combines many high-quality features into a reliable and robust package. This includes adjustable spindle speed, user-friendly control software that is easy to learn and operate, a robust power supply, and a top-tier cast iron frame. The goal is to encapsulate the finest qualities of a full-sized industrial milling machine within a more compact form factor, ideally suited for small businesses and workshops.

While CNC milling machines designed for desktop use may feature a more confined cutting area than larger counterparts, they are fully capable of working with a wide range of materials, including metals and plastics. Many small shops and home-based workshops opt for CNC milling machines, prioritizing reliability and versatility.

Selecting the Best CNC Milling Machine

The best CNC routers and milling machines can efficiently cut through hard and soft materials across various applications, including plastics and aluminum. This is why CNC milling machines can be found in many settings, from small shops to research and development departments.

At CNC Masters, we offer several outstanding CNC Milling Machines online. Each is a desktop CNC mill meticulously engineered to provide exceptional power within a compact and cost-effective package. Regardless of your project’s nature or the materials involved, whether it’s metal or plastic, CNC Masters’ machines empower you to realize your vision. To harness the full potential of these desktop mills, all you require is a computer, a bit of time, and a willingness to learn.

These machines have complete 3-axis capabilities, covering the X, Y, and Z axes. They are fully programmable using G-code and seamlessly compatible with various CAD/CAM programs and open-source software. CNC Masters’ milling machines have the power and precision to tackle projects to the highest standards.

What Makes an Exceptional CNC Milling Machine

We understand that investing in a CNC milling machine represents a substantial commitment. Therefore, we go to great lengths to ensure that all our CNC milling machines meet our stringent specifications. We source the highest-quality components from around the globe and assemble them in-house. This not only allows us to affix our seal of approval on our mills but also provides our customers with unwavering confidence in the reliability and consistency of their CNC milling projects.

Our milling machines can produce numerous parts with the utmost precision and dependability, whether you require them in large quantities or small batches.

CNC Milling Machine Cost

The cost of a CNC milling machine can vary widely, with typical investments reaching into the thousands of dollars. Enterprise-level milling machines, including industrial horizontal mills, can even reach six figures. At CNC Masters, we take pride in offering high-quality and affordable CNC mills, ensuring that hobbyists and small-scale professionals can access top-tier tools capable of handling ambitious projects. If you have any questions, please don’t hesitate to contact us.

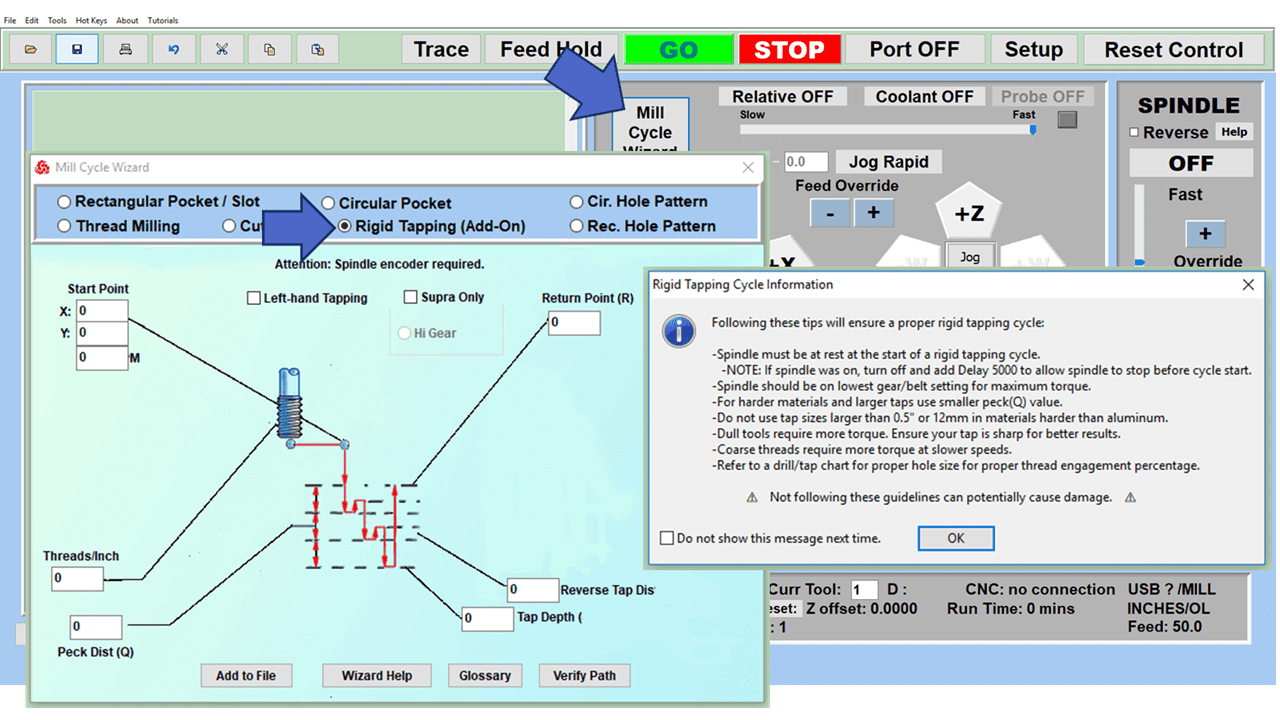

Access Our CNC MX Software Program

Our custom CNC software is included with every purchase of our CNC mills, CNC lathes, and router machines. You can run our CNC software on a Windows 10, touch screen desktop, or laptop PC via a standard USB port connection.

Our CNC Mills

Our milling machines are priced under $10,000, making them an accessible, professional option for hobbyists and skilled machinists.

- Max CNC Mill: 21.5″ x 10.5″ on X and Y axes

- CNC Baron Milling Machine: 21.5″ x 7″ on X and Y axes

- Spindle: 6-speed gear head with oil bath for stronger torque (60 Hz: 196, 388, 662, 893, 1768, 3000 spindle RPM; 50 Hz: 163, 323, 552, 744, 1473, 2500 spindle RPM)

- CNC Jr. Desktop Mill: 19″ x 7″ on X and Y axes, featuring powerful X, Y, and Z-axis micro-stepper motors with a size 34 and 1200 in/oz. of torque, as well as a 2HP, 220-240VAC single-phase spindle motor.