Drilling holes with your cordless drill might have worked fine on your latest small DIY project. But sooner or later, you’ll want to tackle a home improvement requiring holes at specific depths and distances, and you’ll realize that the hand-held power tool isn’t up for the task.

Cordless drills have many uses, but precision drilling isn’t one of them. Once you understand you’ll need the increased accuracy that only a drill press can provide, you have to decide which features you’ll need and how much you’re willing to pay for them.

This buyer’s guide is designed to help you choose a drill press that will give you excellent results in your next project. DIYers need the right drill press’s versatility to successfully complete a wide range of metalworking and woodworking projects.

Ready to step up to a sturdy, efficient, and powerful tool? Here’s what you should know to find the perfect drill press for you.

What are the common uses of drill presses?

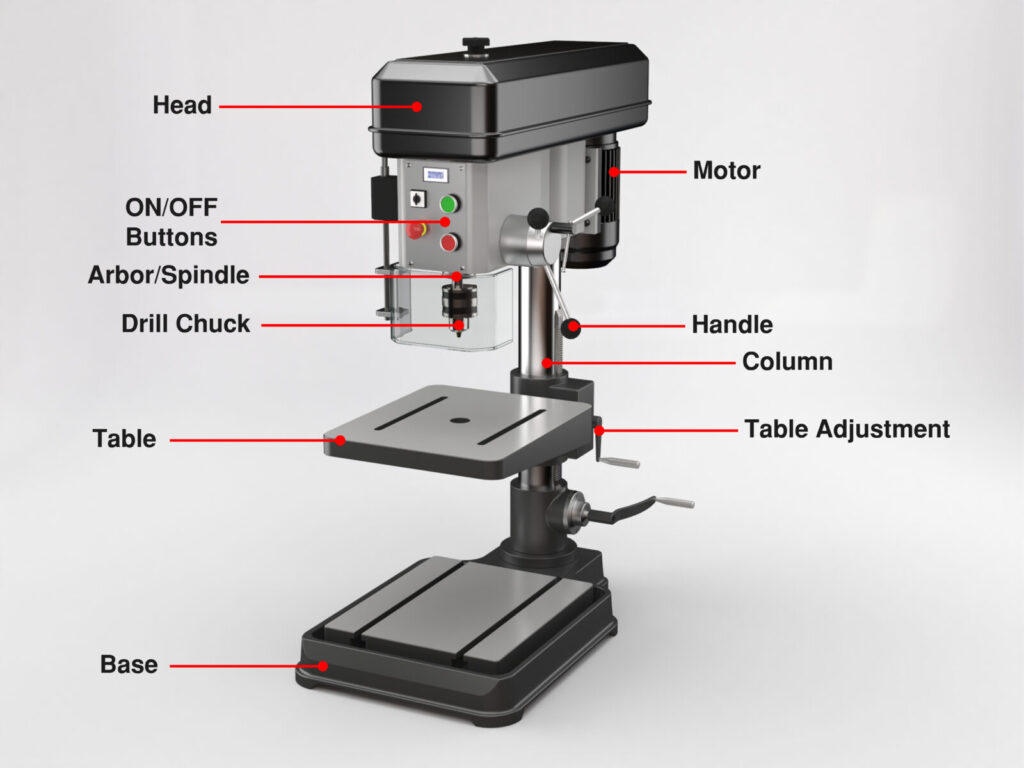

A drill press has a drill chuck that holds the drill bits for drilling holes of various diameters. But that’s where the similarities to hand-held drills end since drill presses are not hand-power tools. The drill press’s head—consisting of a motor, chuck assembly, speed control handle, and feed handle—is set on top of a heavy-duty support column and base. An adjustable drill press table rides along the column and can support a vise.

The support offered to the head assembly, and chuck by the cast iron base and column prevents any movement of the workpiece during drilling, eliminating most quality issues. Woodworkers, machinists, and hobbyists favor the drill press because it offers more power and accuracy, allowing them to drill larger holes and work with tougher materials.

There are many uses for a drill press that go beyond drilling holes straight through a workpiece. Here are a few examples:

- Drilling holes to a specific depth with the help of a depth stop.

- Drilling holes at an angle by tilting the head or the table if the drill press has one of these features.

- Reaming precise holes that require a specific diameter.

- Creating threaded holes with a tap.

- Countersinking holes for a flat-headed screw or to deburr a hole’s edge.

- Counterboring to allow for a socket head cap screw.

- Cutting square or rectangular holes in wood using a mortising bit.

- As a sander. Some drill presses have oscillating spindles with a sanding drum that fits into the drill chuck.

What Are the Main Types of Drill Presses?

The several primary types of drill presses, each with specific uses.

Benchtop Drill Press

As the name suggests, the benchtop model fits conveniently on a workbench/tabletop and takes up minimum space in a small workshop. These drill presses are best for smaller jobs and typically have an 8- to 12-inch swing. (Swing is the distance from the center of the drill chuck to the edge of the support column, times two). The benchtop drill press can drill 2” to 3-3/8” deep. If you’re looking for a compact-size drill press for a garage, these are the best drill press for you.

Floor Drill Press

On the other hand, floor drill presses stand alone and are fastened directly to the shop floor. These floor models offer more horsepower for heavy-duty jobs and larger workpieces, typically featuring a 13-to-20-inch swing and drilling capability of 3 to 6 inches deep.

CNC Drill Press

Combine the power of a benchtop drill press and the precision of a CNC machine, and you get a CNC drill press. These machines utilize technology and software to make precision drills. They’re more and more common today in multiple industries because their drills are accurate. There are also mill drills, which combine a milling machine and drill press.

Magnetic Drill Press

A magnetic drill press allows you to attach the drill to any metal base securely. They’re great for hard-to-reach places on the job site where you need the power of a drill press but need a mobile solution.

What features should I look for in a drill press?

Sufficient Horsepower

What is enough horsepower? As a rule of thumb, you should not settle for less than 1/2 horsepower to ensure you have a powerful motor and adequate speed range. For example, the WEN 4214 has a 5-amp 2/3-horsepower 12-inch drill press. This variable-speed drill press has plenty of power to handle your intense drilling needs. So, there is little reason to spend more on models that offer over one horsepower unless you are drilling large holes in tough metals regularly.

Swing Size

Remember, the swing size is the distance from the center of the chuck to the column times two, so a 12-inch swing means you can drill a hole in the center of a 12” workpiece. If you determine you’ll be drilling holes more than six inches from the edge of your workpieces, you will need to look at something larger than a 12-inch drill press.

No Wobble

The point of a drill press vs. a handheld drill is for power and security. The best drill presses won’t wobble when used. If a drill press does move unnecessarily, it might be time for a new one.

Make Sure the Machine Has a Depth Stop

A depth stop is an essential feature if you are going to be drilling several holes at the same depth. For example, if you need to drill 12 holes and all of them must be 2” deep, the depth stop will ensure that all twelve holes will be the same 2” depth.

Get the Most Stroke Distance You Can Afford

Stroke distance is often referred to as quill travel or spindle travel, and it measures the maximum depth a spindle, drill chuck, and drill bit can travel as the operator rotates the feed handle without moving the table up. More stroke distance (3″ to 5″) typically means a higher price, but it also allows for working with longer drill bits and thicker material and adds to the drill press’s versatility.

Digital Readout

A digital readout, sometimes called digital speed readout, on a drill press is a helpful feature that displays the running speed and eliminates guessing your RPMs. Some DROs also measure the depth of the hole you’re drilling.

Choose a Drill Chuck With a Large Capacity and a Chuck Key

Drill chucks tightened by hand are convenient and eliminate the possibility of losing the key. Still, if you intend to drill relatively large diameters, it’s more secure to tighten the chuck with a wrench or chuck key. Also, a 5/8″ diameter drill chuck is ideal for drilling larger holes.

Get a High-Quality Worktable

You’ll want a table you can adjust up or down depending on the size of the workpiece and the depth of the drilled holes. You can even swivel some of these tables.

Warranty

Make sure a solid warranty backs your drill press. For example, RYOBI offers a 3-year manufacturer’s 10″ drill press warranty that includes an EXACTLINE Laser Guide Alignment System.

Common Drill Press Accessories

- If you’re opting for a benchtop drill press, get a heavy-duty worktable on which to attach it.

- A drill press vise is invaluable for holding smaller parts for drilling.

- Mortising chisels are used for cutting squares and other shapes.

- A built-in LED work light provides direct lighting and reduces shadows.

- Sanding drums for sanding tasks

- Look for a model with a laser guide that aligns with the drill point using crosshair lines on the workpiece. The laser guide allows for pinpoint drilling

How much does a drill press cost?

Drill presses come with a variety of features and accessories that greatly impact their cost. Smaller benchtop drill presses can start as low as $40 – $50 and can be found on eBay, Amazon, or your local hardware store.

For larger drill presses with more features like a JET, prices go up to $10,000 and beyond. Just like with a milling machine or router, you can expect to get what you pay for.

Benefits of Owning a Drill Press

Drill presses provide a level of control and power that handheld cordless drills don’t. They’re faster and allow for more accurate drilling, which allows the user to drill more even and uniform holes.

In addition, a solid drill press will allow you to drill through harder surfaces than a handheld. Many drill presses can handle larger drill bits than handheld drills, which makes them more versatile for larger jobs.

Since drilling is a common job, drill presses are used frequently. A good drill press will last longer than a handheld drill while providing consistent performance.

Is a drill press worth the money?

Yes. Most buyers should strongly consider a drill press because of its accuracy and speed.

Specific tools would be on your must-have list if you were to design a machine shop. First of all, it’s hard to imagine getting by without a milling machine, lathe, bandsaw, grinder machine, and perhaps a router. However, equally essential to your successful shop is the versatile drill press. Whether it’s a Jet floor drill press, a Shop Fox bench top or radial drill press, a powerful magnetic drill, or an entry-level 5-speed drill press from Amazon, you’ll turn to your drill press countless times to make it easier to build things.