CNC machines, particularly CNC mills and lathes, have transformed the manufacturing industry, enabling precision cutting and shaping materials with unprecedented efficiency. However, these industrial powerhouses can seem intimidating and inaccessible to the average hobbyist, DIY enthusiast, or part-time machinist. This perception is changing with the advent of DIY CNC mills, bringing this innovative technology into garages and home workshops worldwide.

This article focuses on CNC milling machines – we’ll save the discussion of DIY CNC routers and 3D printers for another day. Undeniably, a DIY CNC milling machine would be one of the most accurate and versatile DIY CNC projects, capable of machining cast iron or handling a woodworking task while maintaining close tolerances. They level the playing field by bringing the power of factory-grade machines into the hands of beginners and seasoned machinists alike.

Is it cheaper to build your own CNC?

Building your own CNC machine can be cost-effective for those with technical skills and a do-it-yourself spirit. The total cost significantly depends on your design choices such as the working area size, materials, and type of motor you choose.

The out-of-pocket cost of a homemade CNC mill may be less because your own labor is “free”. Construction of a mini-mill is labor-intensive, so if you can earn $30+ per hour elsewhere, purchasing a quality benchtop or desktop CNC mill from a reputable manufacturer might make more sense.

When considering costs, be aware that the higher upfront cost of a manufactured CNC mill often includes features like customer support, warranties, and software compatibility that DIY machines may lack. It’s essential to look beyond the initial expenses and factor in labor, maintenance, part replacements, and potential troubleshooting time.

Why are CNC Milling Machines Expensive?

CNC mills carry a high price tag because of several contributing factors:

- They are precision tools with complex designs

- The materials used to construct CNC mills are often high-quality, durable materials meant to handle intense precision milling without wearing down

- The initial price includes maintenance, software updates, and potential repair costs over the machine’s lifespan

How would I get started building a DIY CNC milling machine?

Design the Machine

Several software programs exist to help you plan your CNC machine, including CAD (Computer-Aided Design) software. The machine should meet your specific needs, so remember the cutting area you need and the type of materials you plan to work on. Also, consider the space available in your shop for the machine. CNC forums can provide a ton of helpful insights. Open Builds is an interesting open source resource to check out as you get started.

Tips for Designing the Essential Parts of a CNC Milling Machine

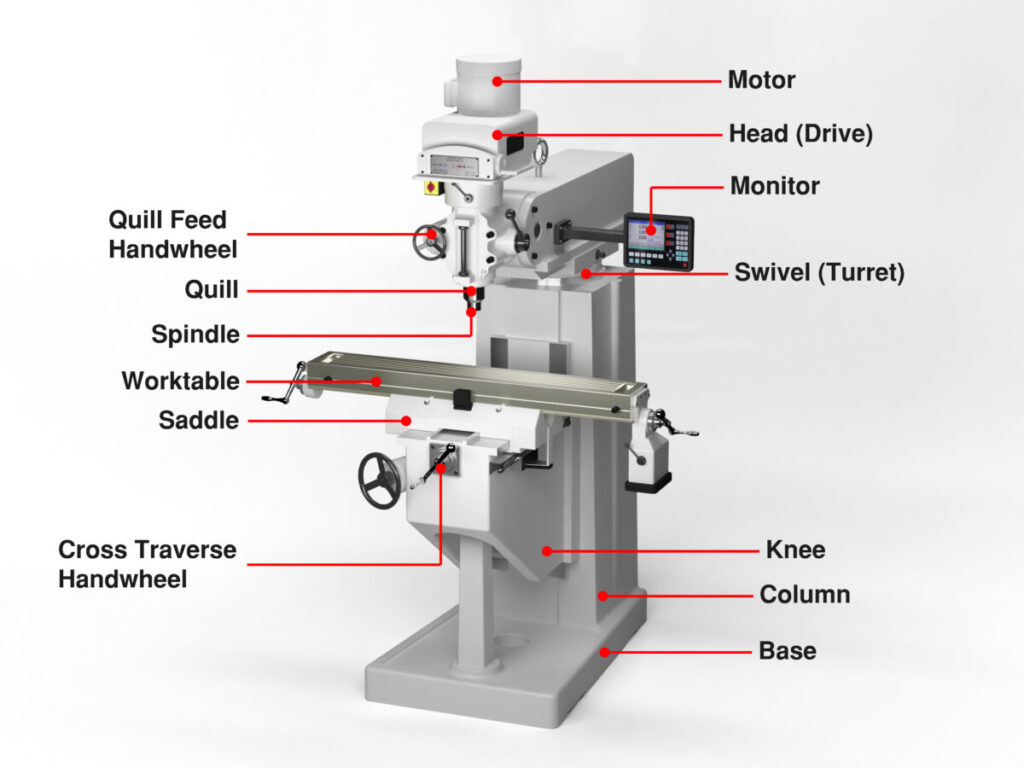

The primary components of a DIY CNC mill include a frame (often made from extrusions), linear rails, lead screws or ball screws, a spindle, servo or stepper motors, a controller, and the CNC software with a G-code interpreter.

The frame provides the structure and rigidity required for precise operations, ensuring the mill can handle the forces generated during milling. The spindle, attached to the frame, holds and spins the cutting tool. The stepper motor, such as the popular NEMA23, is controlled by the CNC software. It moves the spindle and the workpiece relative to each other along the XYZ axes, with the X-axis representing side-to-side movement, the Y-axis in and out, and the Z-axis up and down.

You can make the frame from various materials, including epoxy granite, aluminum, or steel. The choice of material depends on your budget and the precision and stability you require. Aluminum is a good choice; it is sturdy and relatively easy to work with.

The spindle is one of the machine’s most critical parts, and you should choose it carefully. Ensure it has the correct speed and power to cut through the material you plan to machine.

The stepper motors move the spindle around, and their quality and specifications significantly impact the precision and smoothness of the machine’s operation. Choosing suitable motors involves considering your machine’s size, the spindle’s weight, and the type of material you plan to cut.

The controller represents the ‘brain’ of the DIY CNC machine, receives instructions from your computer, and translates them into movement. It controls the stepper motors and the spindle. You can buy a pre-made controller or make your own.

Check out options for buying individual components or kits at websites like https://buildyourcnc.com/CNCPlans.aspx.

Construct the Machine

Once all the parts are ready, you can start constructing the machine. Begin by building the frame, ensuring it is square and level. Next, install the stepper motors and the spindle, aligning them correctly. Connect the motors to the controller and make sure everything moves as expected.

Test your machine

Testing involves sending a design to the controller and letting the machine cut it out. By observing the results, you can make any necessary adjustments to improve performance.

Building a DIY CNC milling machine is challenging. Still, with thorough planning and execution, it can be a satisfying project, providing you with a versatile tool for future DIY projects.

What are the options for a worktable?

The work surface is where you will clamp your workpiece. On many professional machines, the work table has T-slots milled into the surface, allowing you to use T-nuts and bolts to secure your materials or vices. Others use a square piece of 18 mm birch-plywood to fasten the materials with screws and replace them when needed, providing an affordable work surface. You could also use MDF with anchor nuts and bolts, but avoid screws and nails in MDF since it doesn’t grip them as well as a plywood board.

Helpful hint: You could use your newly completed CNC machine to flat mill the work surface and call it your first project!

How challenging is it to build a CNC mill?

Designing and building a DIY CNC milling machine is an ambitious project requiring careful planning, precise execution, and a solid understanding of mechanical and electronic principles. In other words, it’s not for everyone!

Check out this full video of a talented and experienced man building a CNC mill. Remember that some people make things look easy because they know what they are doing, and this young man is an excellent example of this. He has all the tooling, including a nifty portable magnetic drill press, and he is an experienced welder with all the safety equipment and a welding machine. Unless he worked on this project full time, he likely invested at least six months and several thousand dollars into this project.

For a lower-end option, watch “How to Build a Homemade CNC Milling Machine Based on the V-SLOT OpenBuilds System”. Although not in English, this lengthy video is helpful for understanding the details involved. Keep in mind that this and similar Chinese models available at Amazon are not robust machine tools and are limited to cutting wood, PCB, and other lightweight materials.

Advantages and Disadvantages of a DIY CNC Milling Machine Project

What are the advantages of DIY-ing your machine?

Creating your own CNC milling machine offers many advantages, primarily in customization, cost-effectiveness, and educational value.

When you build your own CNC machine, you can tailor it to your specific needs. Whether your projects require a particular size or special modifications, you have complete control over the design. You can adapt the machine’s capabilities to your specific applications, thus ensuring that it perfectly fits your requirements, a luxury not readily available with off-the-shelf solutions.

As for cost-effectiveness, building a CNC machine from scratch can be more economical than buying a ready-made one, especially if you’re a hobbyist or running a small-scale operation. Assembling your machine lets you control the budget and prioritize where you want to invest most, whether in higher quality components or advanced software.

Finally, the educational value of building a CNC machine is immense. The process involves understanding the fundamental principles of CNC technology, mechanical engineering, and electrical systems. It’s an opportunity to acquire new skills and deepen your knowledge in these areas, which can be highly valuable for hobbyists and professionals. A hands-on experience in building a CNC machine aids in troubleshooting and maintenance tasks as you become familiar with every machine component.

Building your CNC milling machine can offer a customized, affordable, and educational solution for machining needs. It’s an endeavor well worth considering for anyone interested in CNC technology.

What are the downsides of DIY-ing your CNC machine?

While undertaking this project can seem exciting, it carries several disadvantages worth considering. The first piece of advice: don’t underestimate the complexity of assembling a CNC milling machine. These machines require intricate calibration and precise installation of components, which can prove challenging for individuals without advanced technical skills.

Second, the time commitment required for a DIY project of this magnitude is considerable. Assembly, testing, and tweaking can consume significant hours you could spend on other projects. Moreover, the process is often trial and error, leading to potential frustration and project abandonment.

Third, cost implications can outweigh the benefits. While the initial perception might be that DIY saves money, the truth can be quite the opposite. The costs of individual parts, tools, and potential replacements for errors can quickly add up, possibly exceeding the price of a pre-assembled machine.

Finally, don’t ignore safety. Improper assembly or use of a CNC machine can lead to severe injuries. Professional manufacturers adhere to stringent safety standards that may not be part of a DIY approach.

While the sense of accomplishment from building a CNC milling machine can be rewarding, the potential drawbacks make it crucial to carefully weigh the decision before embarking on a DIY CNC Milling Machine Project.

Comparing DIY CNC Mills and Desktop CNC Mills from CNC Masters

- Cost: DIY CNC mills can often be more affordable because the price primarily includes components and raw materials. However, CNC Masters’ desktop machines, though more expensive, come fully assembled and ready to use.

- Ease of Setup: DIY CNC mills require specific technical knowledge for assembly and calibration. In contrast, desktop CNC mills are pre-calibrated and ready to use out of the box.

- Support and Warranty: With DIY CNC mills, troubleshooting and maintenance are up to you. CNC Masters, for example, offers warranty and support for their desktop CNC machines.

- Reliability and Precision: DIY CNC mills can vary in reliability and precision depending on the quality of the build and the deflection on the longer axis. Desktop CNC mills from CNC Masters are built with quality components and have rigorous testing to ensure accuracy and reliability.

- Software Compatibility: Depending on the controller, DIY CNC mills can be compatible with various software. Desktop CNC mills from CNC Masters come with their proprietary software, which might limit compatibility with other programs.

- Time Investment: Building a DIY CNC mill requires a significant time investment in addition to skills in electronics and mechanics. CNC Masters’ desktop CNC mills save time since they come fully assembled.

- Safety: Desktop CNC mills from CNC Masters have safety features like emergency stop buttons and shielded wiring. Safety in DIY CNC mills depends entirely on the builder’s precautions and design.

Remember, the choice between a DIY CNC mill and a pre-built one, like those from CNC Masters, greatly depends on your needs, budget, skills, and time availability. Professionally produced machines benefit from years of design refinement and the use of premium materials, ensuring their durability and longevity, which makes a powerful case for choosing a high-quality CNC mill over a DIY alternative.

At CNC Masters, we offer three of the best Desktop CNC Mills, and they are all available online. These CNC machines provide compact power at an affordable price. CNC Masters offers options in small CNC machines to fit your work and budget. We sell only high-quality, USA-built machine tools with ball screws, a warranty, and excellent service – all at a competitive price!

Please email us directly at sales@cncmasters.com, call us at 626-962-9300, or visit our contact page. We look forward to hearing from you!