35+ Useful G-Code and M-Code Commands You Might Not Know

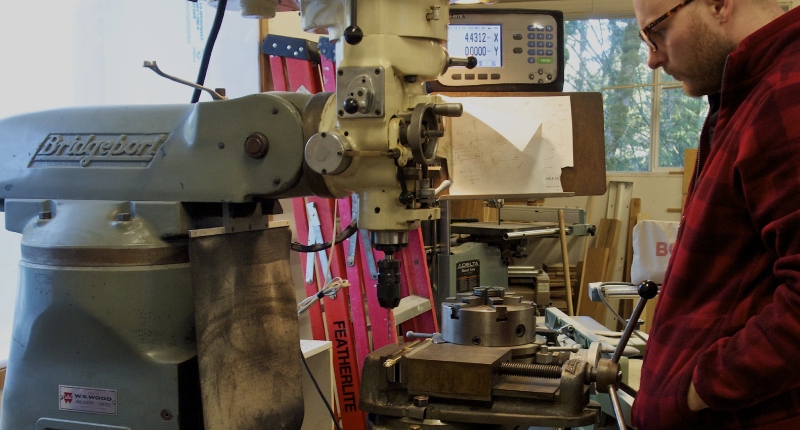

Like most coding languages, G-code looks strange when you first see it. There’s no apparent rhyme or reason, the numbers don’t seem to relate to each other, and the whole thing can appear a bit haphazard. It gets even stranger when you try to tell the codes themselves to the machines they work with. What

35+ Useful G-Code and M-Code Commands You Might Not Know Read More »

Like most coding languages, G-code looks strange when you first see it. There’s no apparent rhyme or reason, the numbers don’t seem to relate to each other, and the whole thing can appear a bit haphazard. It gets even stranger when you try to tell the codes themselves to the machines they work with. What