Machinists looking for a new addition to their machine shop or home workshop face several choices. Which lathe or mill is the best, how large should they be, and which make and model?

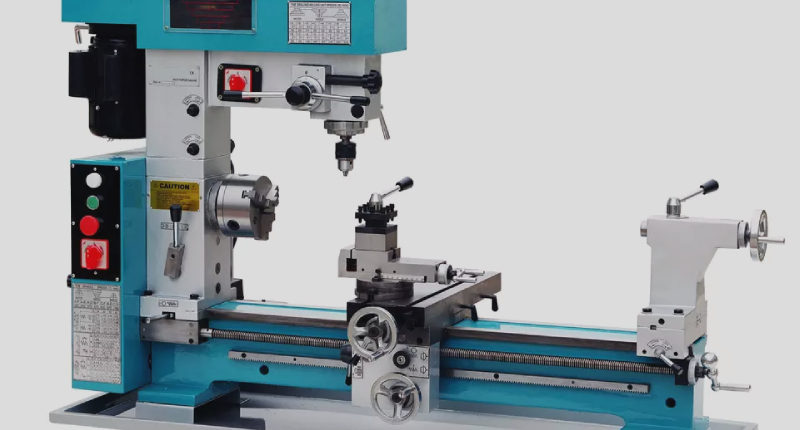

For machinists working in small spaces, lathe/mill combination machines provide an attractive choice. These are typically small lathes with a built-in milling turret that also acts as a drill press. These combos offer machinists the flexibility of multiple operations in a single machine.

Anyone interested in a lathe and mill combo should consider a few things before making a final decision. Here are ten things to know about purchasing your combination lathe machine, milling machine, and drilling machine.

1. What is the Primary Purpose of the Lathe/Mill Combo?

A combo lathe/mill machine shines at jobbing shop projects where the quantities are limited and require turning and milling operations. Of course, they can also be used in production work and are especially useful for secondary operations. As long as you anticipate booking a lathe and millwork, a combo machine should fit the bill.

However, if you intend to machine long shafts between centers, you should ensure you get a steady rest. Other features are a four-way turret tool post to hold the lathe tools and a rotating vise.

2. What are Your Machine Size Requirements?

The DIY machinist or home shop hobbyist will usually appreciate the reduced footprint of a lathe/mill combo. With space being at a premium in a small shop, the space-saving design of a benchtop lathe and mill combo makes it a significant benefit.

However, a reduced footprint can quickly turn into a disadvantage if you start taking on larger workpieces that don’t fit on your worktable. Think about the size of the pieces you might be working on in the future, and match it with a larger lathe/mill combo that gives you the flexibility to machine more significant parts. In any case, be sure to check the combo’s cross-slide travel distance.

3. What is the Horsepower of the Combination Lathe and Mill?

Will you be working primarily on metalworking or woodworking projects? Although 3/4 horsepower is typical for a lathe/mill combo and will work for either, if you want to use the turning portion exclusively as a metal lathe, consider 2 HP on the lathe motor and a 3/4 HP motor on the mill. If wood turning is your thing and you plan to use it as a wood lathe, the combo’s low horsepower might not trouble you.

4. Does the Combo Operate at Variable Speeds?

You want a machine with variable speeds on the lathe and mill. Also, check the spindle speed range since some will have a limit of 1300 RPMs, while others will span from 50 to 2500 RPMs. Make sure the speed range covers the types of work you need.

5. What is the Spindle Bore Size?

Spindle bore size refers to the maximum diameter of stock that you can feed through the headstock. So, if the machine has a spindle bore of 1.1″ inches, you can work on a long piece of 1” diameter stock. However, if you want to machine short components of 1.25” stock, you’ll have to cut it to length ahead of time on a bandsaw since it won’t fit through the metal lathe’s spindle bore.

6. Does It Come With a Digital Readout?

A digital readout (DRO) gives you so much essential information you don’t want to be without. If your combo has not provided a DRO from the factory, at least ensure it has mounting holes so you can easily add one later.

7. What Type of Drill Chuck is Provided?

Although there are two kinds of drill chucks—keyless and keyed, most machinists prefer keyed chucks since they typically have less runout. Also, check that a chuck arbor comes with the machine. The arbor is a steel shaft with two ends, one ground to fit into the machine’s tailstock and the other ground to fit into the rear of the drill chuck for holding drill bits and other cutting tools.

A 15-pc. collet toolset should also come with the mini lathe since collets help prevent the “whipping” action from long pieces of small diameter stock sticking out from the back of the tailstock.

8. Find Out if a Self-Centering 3-Jaw Chuck is Part of the Package

A lathe chuck holds the workpiece for turning or drilling. Each jaw of a three-jaw chuck fits into a scroll plate, meaning the jaws move simultaneously when tightened by the chuck wrench. Thus, the term self-centering chuck.

9. Who is the Manufacturer of the Combo Lathe/Mill?

Lathe/mill combination machines can work well, but much depends on the manufacturer, like other machine tools. If it isn’t a high-quality brand, you could lose many of the benefits of the machine to inferior quality.

For any machine tool to produce excellent parts, it must be built sturdy to face the challenges of the machine shop. And that goes for routers, grinder machines, table saws, or bench lathes. So, check out the combo’s manufacturer to be confident in your choice.

As mentioned, identify the primary purpose of your machine and any size requirements. Be sure you need the flexibility of a combination lathe and mill because it might be that a dedicated machine could work more appropriately for your purposes.

10. Might a Dedicated Machine Be Better?

For example, suppose you anticipate a steady supply of long production runs for a lathe in the future. In that case, you are better off investing in a compact CNC turning center and adding a space-saving desktop mill for any milling and drilling tasks. Since combination lathe/mill machines generally surrender power for versatility, manufacturing more challenging materials or significant production runs is better achieved on a single-purpose machine.

Check Out Our Lineup of Small-Footprint Lathes and Mills

After you have determined that two separate machines would better serve your needs, your next step is to find machine tools of the highest quality and most compact footprint for your work area. Advanced lathes and mills that provide the flexibility of operating in either manual or CNC mode on a smaller footprint could be the answer.

The CNC 1340 Turning Center from CNC Masters is an elite lathe seamlessly converting between CNC and manual modes. The 1340 and its bigger counterpart, the 1440, are rugged machines designed for the hobbyist or professional to deliver high-level performance while providing exceptional value. In addition to all the features of more expensive lathes, our space-saving turning centers offer a thread-cutting range of 4 to 112 TPI or metric threads from 0.25 to 11.

Regarding versatility, precision, and conserving precious space, our desktop CNC milling machines are second to none. With a range of features, including variable spindle speed, easy-to-learn control software, user-friendly controls, and a robust power supply, our desktop mills provide the elements of higher-priced machine tools combined with the convenience of a milling machine that fits conveniently in a small workshop.

At CNC Masters, we have been providing high-quality CNC mills, milling machines, and CNC lathes for over 20 years. Business owners, machinists, scientists, researchers, teachers, and even hobbyists have discovered our California-based company’s superior quality, competitive prices, professional service, and an excellent warranty.

Call us at 626-962-9300 or email us at sales@cncmasters.com. Better yet, call us for an appointment and visit our facility in Irwindale, CA.