As CNC milling machines become more popular and manufacturers of all sizes can now afford them, manual milling machines continue to fade in importance. Some companies are trying to decide whether to switch their machining operations to CNC technology. Should they transition their milling operations from manual machines to CNC machining centers or their manual lathes to CNC lathes? Do you still need that manual toolroom grinder?

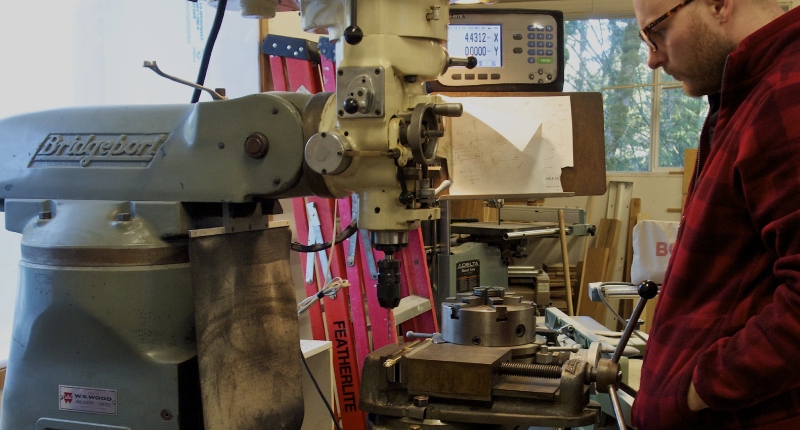

However, although CNC machining overshadows its manual counterpart, machinists still rely on them for specific tasks, and manual machines keep earning floor space in the modern machine or fabrication shop. Vertical milling machines are remarkably versatile, even more so than horizontal mills or bed mills. A shop without a manual Bridgeport mill, or any vertical knee mill for that matter, is unthinkable.

So, it’s not so much a matter of keeping one or the other (you likely need both CNC and manual mills), but in which situations do it makes sense to turn to the manual mill, and when does CNC milling provide the most benefits?

Before delving into when to use a manual mill, let’s briefly discuss these tried-and-true machines.

What is a Manual Mill?

A manual milling machine removes material from the surface of a workpiece with special cutters, creates slots using end mills, and drills, taps (internal threading), bores, and reams holes. Because many manual mills include a digital readout (DRO), manual milling and drilling are precise and relatively fast. Depending on the machine’s table size, you can add an indexer or rotary table to a vertical mill’s table to expand the types of parts the manual mill can produce.

Milling machines remove material along the X-axis, Y-axis, and Z-axis. Manual mills are not automated and typically require a machinist or experienced operator to use the machine correctly and safely. The operator determines the spindle speeds, feed rates, and depth of cuts, but most milling machines have power feeds, eliminating the need to “hand crank” the table during vertical machining.

Like a CNC mill, you can clamp the material directly to the machine’s table surface or hold it in a vise that has already been fastened.

Manual Milling Machine Advantages

Considering buying a manual mill? Here are some of the benefits you would get.

Initial Cost

The most obvious and immediate value you would see is in the initial cost. CNC technology is sophisticated: the machine tool, computers, and software enable them to complete complicated projects, but they are expensive.

Perfect for Small Projects

Manual machines are ideal for small projects. For example, if you need to add two tapped holes to a cast iron block, or you want to replace a broken key and have none in stock. Neither of these jobs requires programming or is complex, so why go through the extra operations when you can jump on the mill and finish the job in minutes?

Your Best Customer Needs a Part Today

Your customer might be demanding or could have a true emergency. Either way, you don’t want to have to tell them all your CNC mills are booked up with long-running projects. Instead, use your idle manual universal milling machine and put your best machinist on it. You’ll pick up an “atta-boy” and get to charge your premium rate in the process.

The manual milling machine is a lifesaving backup for your CNC machine tools, especially if you employ an experienced machinist to run it.

The Workpiece is Too Large for the CNC Mill

You often need to machine specific areas of a large workpiece by moving and re-clamping it multiple times along the table. Whether you’re machining it on a Bridgeport-type knee mill, a horizontal milling machine, or a lathe mill combo, you will get through it much more quickly and efficiently on a manual mill.

You Need to Drill a Horizontal Hole or at an Angle

It might not happen often, but there are times when you need a hole or two drilled parallel to the work table, but you don’t own a machine capable of horizontal machining. Here is where the versatility of a variable-speed vertical knee mill comes into play. You can swing the spindle motor ninety degrees and drill the hole horizontally using collets if a drill chuck causes clearance issues.

CNC Mill Advantages

If You Must Create Highly Complex Parts

CNC milling is technologically advanced, meaning you can machine components that would be virtually impossible on a manual milling machine. You would always choose a CNC mill when you must machine multiple surfaces and want to do it on a single setup.

When Precision is Critical

CNC machines are precise and can hold tight tolerances. Unlike manual mills that are susceptible to human error, CNC mills rely on computer technology. Once the design and dimensions are in the system, each part should come off the machine identical.

During High-Production Runs

CNC milling machines shine on production projects. For instance, if you book an order to machine 10,000 cast iron pipe fittings and have promised a short turnaround, there is no need to consider any machine other than one of your CNC mills. They will turn over most pieces in the shortest time with the lowest labor costs.

When Repeatability Matters

And uniformity always matters. One of the advantages of CNC milling machines is they can produce the same part repeatedly. Low scrap rates, quicker turnovers on larger quantities, accuracy, and the ability to handle the most complex geometry are all reasons to turn to the CNC mills instead of the manual mill.

Some Milling Machines Transition Between CNC and Manual

The Supra CNC Vertical Knee Mill from CNC Masters offers the best of two worlds in one excellent milling machine at a reasonable price. It’s a CNC milling machine with all the benefits of the latest technology, and it quickly switches to a manual machine for those quick jobs that pop up during a typical workweek.

The Supra comes in two table sizes, has an excellent warranty, and, best of all, it’s made right here in the USA. Contact the pros at CNC Masters for more information on the Supra and our other CNC machines. Whether you’re a seasoned machinist or a hobbyist, you will receive top-notch service with any of our excellent machine tools!

Image source: https://www.flickr.com/photos/dale_simonson/13907754106