In many manufacturing facilities, the toolroom is an area, usually segregated from production, where tools such as jigs, fixtures, and dies are stored. It’s also where these tools are inspected and repaired when they are returned after a production run.

The tools referred to in this context are typically not hand tools but expensive, complex assemblies installed into production machinery on the shop floor. Examples of these tools include a progressive stamping tool and die set to form metal parts and a mold assembly for plastic injection molding.

Since these dies and fixtures sustain normal wear and tear—and sometimes accidental damage—they must be repaired or replaced occasionally. For those operations, machine tools are placed within the toolroom, and specially trained machinists also called tool and die makers, perform the repairs or produce replacement parts using these machines.

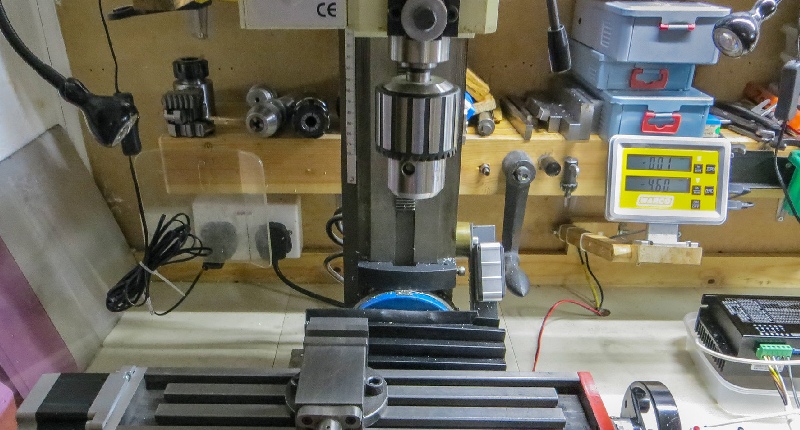

There will undoubtedly be at least one toolroom mill among the machines in the toolroom, including a lathe, saw, and grinder. Here is what makes it unique.

What is a Toolroom Mill and What Sets it Apart?

A toolroom mill is a milling machine, although usually smaller and more compact. Toolroom mills produce precision work on a reduced scale: typically one-off parts similar to a job shop that creates prototypes. These machines could be standard milling machines or small vertical machining centers (VMC) complete with an automatic tool changer (ATC).

Many smaller shops prefer a standard-sized toolroom milling machine so they can use it as a backup for operations unrelated to the toolroom. The ideal solution for these shops is a space-saving CNC knee mill that quickly converts to a standard mill while retaining the functionality of a full CNC model.

Although Haas CNCs, with their TM-2P and TM-3P models, have name recognition, a better candidate for a CNC toolroom mill comes from an American-made brand: CNC Masters, a leader in desktop CNC machines. They offer manual and CNC mode in one machine tool and plenty of features to qualify it as a CNC toolroom mill. Look at the following important toolroom mill features; the CNC Masters mills have every one of them.

What are the Essential Features Specific to a Toolroom Mill?

As you shop for a toolroom mill, remember the space you can allow for it, the type of work you anticipate, and who will operate it. Then, look for these features:

- Small footprint: Working within the confines of a toolroom, these milling machines are typically compact, large enough to handle the bulkiest jigs, fixtures, and dies but nothing more significant. Vertical knee and benchtop mills generally occupy significantly less space than bed mills.

- Precision: Tool and die work requires precision, so you need a machine tool that consistently holds tight tolerances. Although a toolroom mill can fill in on production work, that isn’t its primary function.

- Affordability: Even though toolroom mills are precision machine tools, they are affordable for minor operations. For example, CNC Masters offers their CNC Baron, an efficient and compact cast iron milling machine, for a starting price under $6,500.

- Flexibility: Sometimes, you need a 3-axis CNC for complex fixtures and molds, while at other times, you merely want to hop on a manual mill for a tapped hole or quick slot. The option of manual or CNC mode in one machine tool makes a machinist much more productive.

- Shallow learning curve: Your CNC toolroom mill should be easy for any beginner or experienced machinist to learn and operate.

- Capable of 4th-axis CNC: Besides the X and Y-axis table movements and the Z-axis quill and knee movements, a 4th-axis rotary table offers even more options for machining complicated parts.

- Coolant base: Directing coolant at the cutting tool when machining the tough material used on dies and fixtures keeps the temperature in check, prevents tool failure, and washes the chips away from the part.

- Taper spindle: The R8 taper, found on Bridgeport-type mills, gives you a more comprehensive selection of tooling, such as end mills and chucks, typically at a lower price.

- Conversational programming with G-Code: Conversational CNC is programming G-code by asking the programmer questions to create operations similar to those a manual machinist might use. It is an option built into many CNC controls.

Do the New Breed of Mini-Mills Qualify as Toolroom Mills?

CNC mini-mills meet all the criteria for a toolroom mill, especially the tiny footprint, and affordability. However, the determining factor is whether the size of the worktable and its travel limits are substantial enough for the work you have in mind.

For instance, the CNC Max Tabletop Milling Machine from CNC Masters has 21.5″ of X-axis travel and 10.5” on the Y-axis. A 2-horsepower motor generates 4,500 RPMs, while ball screws on all three axes provide precision and accuracy. The machine’s head tilts for angled drilling, horizontal milling, slotting, and more.

The MAX CNC Mill has a cast-iron body, sliding dovetail ways, and tapered gibs on the square column for accuracy, repeatability, and alignment. It is a versatile benchtop CNC mill offering primary or secondary CNC machining applications. And you can add a fourth axis to machine cylindrical parts such as gears, fan blades, and splines.

You get all this for under $6,000!

Advantages and Disadvantages of Toolroom Mills

A toolroom mill has advantages over a full-size milling machine, but there are also some disadvantages.

Toolroom Mill Pros

- Cost: You can purchase a new CNC mini-mill for under $6,000 or a compact toolroom CNC knee mill starting at $12,500. That’s a fraction of the price of a new full-sized milling machine at $100,000 and up

- Technology: For CNC mini-mill and vertical knee mill prices, you get a boatload of technology, especially if your package comes with CAD/CAM software

- Size: Another benefit of the mini-mill or the knee mill is its small footprint. Mini-mills fit on a desktop or bench, often called “desktop” or “benchtop” mills. Bridgeport vertical knee mills take up little space and fit comfortably in the corner of the toolroom.

Toolroom Mill Cons

- Size: Yes. The size of a compact toolroom mill can also be a disadvantage if you must repair or produce a part that doesn’t fit on the worktable. The machine is too small for some parts, and you could experience rigidity issues on more challenging materials

- Capability Problems: You may not be able to take deep cuts on carbon or stainless steel with most mini-mills because they are not as rigid as a full-sized machining center. Many are designed to machine plastics, wood, and soft metals like copper and aluminum. On the other hand, CNC knee mills do pretty well with roughing and hogging operations

An Example of the Ideal Toolroom Mill

Considering the best features of a toolroom mill, is there a specific machine tool meeting all the criteria with few or none of the disadvantages? The good news is that one CNC milling machine has all the best features of a toolroom mill: the CNC Supra Vertical Knee Mill from CNC Masters.

With a 62.5” x 57” footprint, the Supra is a compact and versatile mill capable of CNC or manual control. Repeatability within 0.0005″ defines the Supra as a precision machine worthy of the tight tolerances of toolroom applications. Easy to learn and operate, the Supra starts at $12,500, and for an additional $1,500, you can add a rotary table and have a 4-axis machine.

If you have questions, please email us directly at sales@cncmasters.com or call us at 626-962-9300. You can also visit our facility in Irwindale, CA. Please get in touch with us for an appointment, so we can give you our undivided attention and ensure we have a machine up and running for your visit.

Featured image courtesy of Tudor Barker