If you ask a machinist how they cut a slot into a workpiece, they will answer that they used a milling machine, as if that should explain everything. However, to be specific, that person should tell you which of the approximately ten types of milling machines they chose to machine that slot, why they decided on it, and whether there was another type they could have used if they had one in their shop. Who knew there were so many different types of milling machines?

CNC milling machines have encroached on much of the territory that once belonged to machines that went by the name of drum milling machines, C-frame milling machines, and simplex manual milling machines.

Let’s look at ten types of milling machines that still occupy floor space in the modern machine shop.

1. Vertical Milling Machine

The most common type of mill, the vertical milling machine, has a vertical spindle for attaching milling cutters, such as end mills and face mills, for various milling operations. The machine is used for machining grooves, slotting keyways, producing flat surfaces, and drilling and boring holes.

Vertical mills use different cutting tools with cutting edges to remove material from workpieces made from metals, wood, plastics, etc. Today, vertical milling machines have computer numerical control (CNC) and are operated manually or combined. The machine’s worktable moves horizontally right to left, in and out, and sometimes up and down but always perpendicular to the spindle axis. On some vertical mills, the table does not move up and down; instead, the spindle head moves.

Prices on vertical milling machines can start at $6,000 for a desktop CNC machine for hobbyists to $500,000 for 5-axis machining centers. Used manual machines typically come in between $10,000 and $20,000 depending on their size and condition.

2. Horizontal Milling Machine

Some call it a plain milling machine, but for most machinists, it’s a horizontal milling machine, so named because the spindle is parallel to the worktable instead of perpendicular as with the vertical mill. However, like the vertical mills, the machine moves along three axes, but the cutting tools will be mounted horizontally.

Besides the horizontal spindle, the machine also contrasts with the vertical mill in that it can use a horizontal arbor featuring different cutting tools than the vertical mills. Horizontal milling machines tend to be more rugged, and you’re likely to see them working on larger workpieces and heavy-duty roughing cutting operations.

Most horizontal milling machines are of the CNC variety and used models range between $15,000 and $85,000, while a new machine will start at $150,000, depending on its size and make. You can pick up a used standard horizontal mill for a few hundred dollars up to several thousand or a new one for $200,000.

3. Universal Milling Machine

One of the most versatile standard machines you can own, the universal milling machine performs various milling operations since it can be set up as a horizontal or vertical milling machine. Adding attachments such as an indexing head, slotting attachment, or rotary table increase the machine’s versatility.

Many shops use the universal mill to produce tooling like milling cutters, reamers, drills, etc. Aside from the CNC milling machine, no machine on this list can perform as many machining operations. Helping this is a worktable that swivels up to 45 degrees on both sides, allowing for helical milling.

A sizeable universal milling machine with 47” longitudinal movement is $130,000 new and used between $10,000 and $15,000.

4. Vertical Knee Type Milling Machine

These machines are sometimes referred to as turret milling machines, Bridgeport-type mills, variable-speed vertical milling machines, or knee-and-column milling machines. However, vertical knee mills use rotary cutting tools, like end mills and face mills, to remove material from a workpiece. These cutting tools differ from the lathe machine, where the workpiece rotates, and a single-point tool removes material similar to a planer.

The milling cutters are held vertically, and the workpiece is clamped in a horizontal position on the machine’s worktable. The table can be raised and lowered for Z-axis movement, or a quill can provide up-and-down movement.

Vertical knee mills are easy to operate, take up little space, and offer versatility since they can double as a drill press and, on some models, can be CNC and manually operated on the same machine.

Today, a new standard Series I knee mill sells for $27,000. Compare that to a new comparably-sized CNC Masters Supra Bridgeport-type knee mill at around $13,500!

5. Bed Type Milling Machines

With a bed-type milling machine, the worktable is placed on a fixed bed, allowing longitudinal movement in the X and Y axes. However, since there is no knee on a bed mill, the bed cannot move in a vertical direction. Instead, the bed mill’s vertical axis (Z-axis) is provided by the vertical spindle, enabling the bed mill to provide a 3-axis range of movement.

Although bed mills and vertical milling machines are similar in construction, they are two different types of milling machines. However, bed-type milling machines are typically more rigid than knee mills and are preferred with more substantial projects and heavier workpieces.

6. CNC Milling Machine

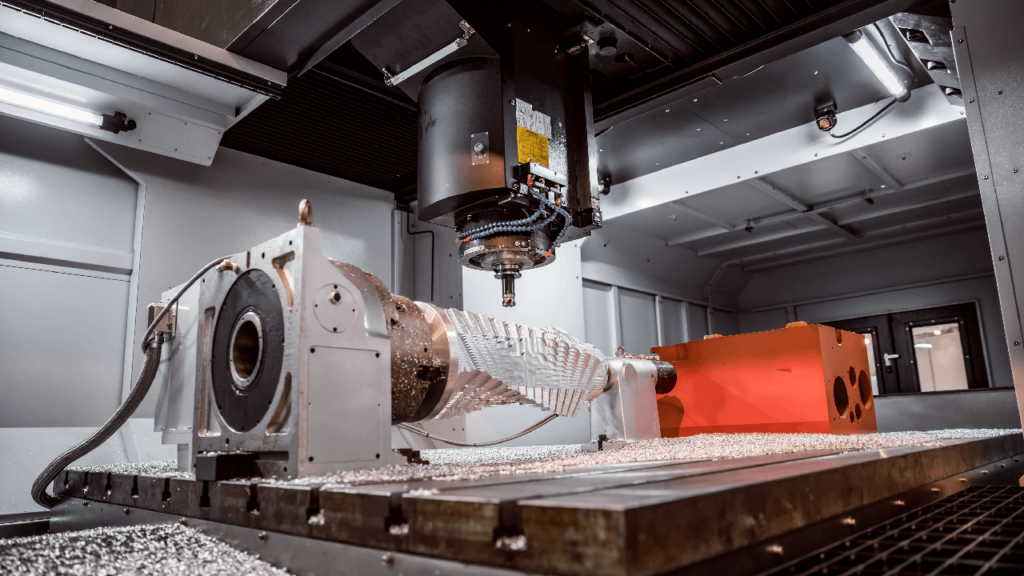

Also known as computer numerical control milling machines, CNC mills are computer-controlled and work with minimal human interaction. Cutting tools are programmed to remove material from flat or contoured surfaces, and cutting materials is typically faster than with manual machines. As a result, CNC milling machines are excellent for production work. Still, because they can machine complex shapes, they are also ideal for custom-designed parts requiring precision, detail, and a better surface finish.

As with any type of machine used for milling, a CNC milling machine relies on rotary cutters moving along multiple axes to complete the milling process. Various types of CNC machines can operate on several axes (sometimes five or more) to produce the kind of complex parts you would find in the aerospace industry.

CNC milling machines are vertical and horizontal machining centers with features including automatic tool changers, tool magazines, enclosed worktables, and coolant systems, all designed for high-quality machining.

Excellent CNC Bridgeport-type vertical knee mills are under $15,000, while large multiple-axis machine tools could cost your company $500,000!

7. Tracer Controlled Milling Machine

Any metal pattern shop producing cast iron patterns for automated foundries in the 1970s had several tracer mills on their shop floor. These machines used a stylus to follow a pattern (usually made of wood and built by expert wood patternmakers) while multiple heads with ball end mills machined cast iron blocks to reproduce patterns, cams, and other contoured surfaces in cast iron or some other metal.

Although tracer-controlled milling machines were standard equipment several decades ago, high-speed 3-axis CNC mills have long replaced the wooden patterns and the talented wood patternmakers who created them. Today, a CNC programmer using sophisticated manufacturing software takes the place of the patternmaker and avoids the pattern altogether.

Since the tracers have lost much of their demand, you can buy them for a few hundred dollars.

8. Column Milling Machines

The column milling machine, or column and knee type, is a blanket term to cover a few of the most common machines, including vertical and horizontal milling machines. So named because the vertical column is attached to the base, and the knee is mounted to guideways allowing it to move vertically.

The column is the primary supporting frame of the knee, worktable, and overarm while housing the driving mechanisms for the spindle and table feed. Column milling machines were typically used to machine car parts, but they work well for operations in various industries.

Since column milling machines cover an extensive range of machines, their costs will vary from a few thousand dollars to hundreds of thousands.

9. Duplex Milling Machine

Duplex milling machines are a combination of two machines placed opposite one another. The two machines work separately or as a single unit when the workpiece is machined with two spindles simultaneously. Duplex spindles can move either horizontally or in vertical directions. And they can be either CNC machine tools or manual machines.

10. Rotary Table Milling Machine

A rotary table is an attachment fastened to a milling machine rather than a separate machine. Typically clamped to a vertical milling machine, it enables precise positioning or allows for cutting round shapes. The rotary table can be fastened either horizontally (flat) on the table or vertically, depending on the shape of the finished part. It can also be operated manually or by CNC control.

Most rotary table attachments start at a few hundred dollars up to about $1,500.

Get the Best of Both Worlds in Your Next Milling Machine

The CNC Supra Vertical Knee Mill is a versatile machine tool from CNC Masters offering computer numerical control and manual-driven operations in one product. This innovative machine enables the machining of complex parts through CNC technology and also provides the option of manually machining simple parts by turning the handwheels.

However, the Supra’s versatility doesn’t stop there. It’s a machine at home on the shop floor of the largest corporation or in the home workshop of a one-person operation or hobbyist. For smaller companies, start machining your parts at a fraction of the cost of outsourcing them. Larger companies get the benefits of a CNC machine and also one that machines simple parts quickly and effortlessly.

Please email us directly at sales@cncmasters.com, call us at 626-962-9300, or visit our contact page. We look forward to hearing from you!