CNC milling machines have transformed the metalworking world over the last several years. Amid all the enthusiasm for these fantastic machine tools, we often overlook the standard-type milling machines that contribute versatility and productivity to our operations, sometimes at a lower initial cost.

A universal milling machine is a variation of the knee-type milling machine, but it can perform more functions than a standard mill. Because it isn’t discussed as much as machining centers and Bridgeport knee mills, some think it’s new to the metalworking industry. However, the first universal milling machine was created in 1861 and is still popular today.

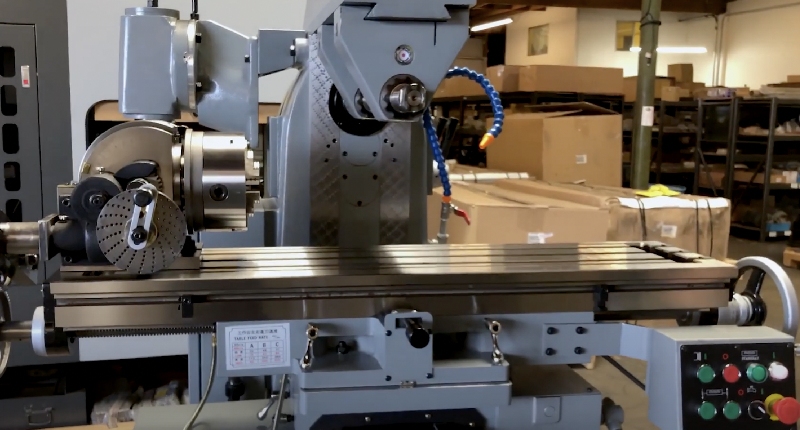

Universal milling machines can handle an array of solid materials on their long table surface with a universal milling head suspended above it. These machines are typically durable since they are made from heavy-duty cast iron.

Here are a few things you should know about them:

What is Special about a Universal Milling Machine?

One noteworthy feature of the machine is it can be transformed from a universal horizontal milling machine into a vertical milling machine by removing the arbor support brackets and the horizontal arbor and attaching a vertical milling head using several bolts. Changing to a vertical milling head increases the possibilities of the work you can perform.

Also, the worktable of the universal milling machine can swivel 45º on either side to enable helical milling work. Also, various attachments, such as a rotary table and indexing head, or dividing head, make it adaptable to more milling operations than other machine tools. Working as a horizontal or vertical milling machine enables the use of many other milling cutters and more types of machining.

A universal milling machine has a more comprehensive range of motion than the typical milling machine. For example, these machines usually have an automatic feed and rapid traverse on the X-axis (left to right), y-axis (in and out), and Z-axis (up and down). And, as mentioned, it operates vertically and horizontally, adding to its capabilities.

Why is it Called a Universal Milling Machine?

The name Universal Milling Machine comes from its capacity to function as a horizontal and vertical milling machine. Although it looks like a standard knee mill at first glance, a closer inspection reveals a horizontal ISO 50 spindle taper above the table with separate controls for spindle speed and direction.

Above the horizontal spindle is a movable ram with a drive motor traveling on dovetail ways on one end. On the other end is a universal swivel head that you can rotate to either side or use as a vertical milling head using the attached overarm to position it. The vertical spindle can be removed and replaced with a horizontal spindle arbor support installed on the ways for line-boring or gang milling with multiple milling cutters.

Depending on the type of work you’re doing—high-precision or rough cuts—you can devise numerous combinations of features and attachments to accomplish it. When you purchase a universal milling machine, you can match the table size and table travel to the type of work you anticipate.

You can also add helpful options such as a digital readout (DRO) on the X/Y/Z axes for high-speed, accurate milling, a centralized lubrication system, and a coolant system. Although the specific capabilities of each universal milling machine might vary considerably, these machines are united by their versatility, flexibility, and ability to do the operations of multiple machines in one tool.

What are the Differences Between a Plain and Universal Milling Machine?

Plain milling machines and universal milling machines have much more in common than they have in contrast. For instance, they both have worktables with t-slots for clamping. They move along the X/Y/Z axes at a designated feed rate, and they each move their X-axis and Y-axis by either automatic feed or a handwheel.

However, there are features of each that set them apart:

- The universal mill has the versatility to perform as a vertical and horizontal milling machine.

- Although the plain and universal milling machine each has three table movements (longitudinal, cross, and vertical), the universal milling machine adds an ability to swivel, giving it direction at an angle to the spindle.

- With the universal milling machine, it’s possible to create spur, spiral bevel gears, twist drills, reamers, milling cutters, and numerous milling, drilling, and cutting operations.

- The plain milling machine tends to be more rigid in construction than a universal milling machine of the same size

- The plain mill is particularly suited for manufacturing operations, while the universal type is a tool room machine intended to produce accurate work.

What are the Disadvantages of a Universal Milling Machine?

Even though universal milling machines are durable, efficient, and reliable, they can be more complicated and high maintenance than more straightforward Bridgeport-type milling machines, for example. The complexity of these machines means they have more components to break down and require extra upkeep.

In addition to being more costly to buy and maintain, universal milling machines tend to be more dangerous to operate because they have all those extra parts to crash, causing potential safety issues.

Does Anyone Still Sell Universal Milling Machines?

Since inexpensive CNC knee mills are available for most budgets and can take your manufacturing business much farther than manual machines, universal milling machines have dropped in popularity. However, some companies like Huron, Deckel, and Knuth, and Kent continue successfully selling these versatile machines.

Speaking of Versatility!

CNC Masters highlights their Supra Vertical Knee Mill with all the latest features to enable you to machine complex parts or increase productivity. The Supra allows for either CNC automation mode or optional manual machining when a quicker operation is required.

Along with our line of lathes, the Supra is a high-quality, USA-built knee mill with ball screws, a warranty, and excellent service, all at a competitive price! Please email us directly at sales @ cncmasters.com, call us at 626-962-9300, or visit our contact page. We look forward to hearing from you!