Every machinist since World War II has experienced a Bridgeport milling machine at some point. Many talks about these versatile knee-type vertical milling machines in the same respectful tone usually reserved for their first muscle car as a teen. The machines were once so popular that machinists began calling all vertical manual milling machines “Bridgeport,” even though they were manufactured under another brand name.

So, what about these manual vertical knee mills makes them the most recognizable machine tool in the trade? Here are ten things to know about Bridgeport machines that have set them apart from other manual mills:

1. Why is it Called a Bridgeport?

The name originated in Bridgeport, Connecticut, where Rudolph Bannow designed the first Series I standard mill in 1936. The knee mills went on sale in 1938 and were sold by Bridgeport Machines, Inc. Within a few years, they became the standard for vertical mills, and their popularity continues today.

2. Who Makes Bridgeport Mills Today?

In 2002, the machine tool conglomerate Hardinge, Inc. acquired Bridgeport and began making variants of the Bridgeport mill while continuing to manufacture the Bridgeport Series I machine. Many of the newer models of Bridgeport made by Hardinge are CNC machines, meaning they drive the machine transmission using program codes.

V-Series, GX-Series, and XR-Series are today’s models of the Bridgeport mill. These machines are enclosed and have several advanced features.

3. What are the Main Parts of a Bridgeport Mill?

Column

The main casting on the Bridgeport mill is the column, which provides support and stability for all the other machine components. Weighing in at approximately 800 pounds, the column is the heaviest piece on the Bridgeport.

Knee

The knee is another heavy-duty casting supporting the worktable, and it rides vertically on a dovetail on the machine’s column. Depending on the height of the workpiece, Bridgeport’s operator can raise or lower the table manually, using the vertical feed crank, allowing knee travel along the Z-axis. Once the knee is in the correct position, the operator can lock it.

Saddle

The saddle supports the worktable and is driven by a screw. A dovetail alignment supports it as it moves along the Y-axis (in and out), either by manually turning a cross-feed crank or using a power feed. It can then be locked in position. The sliding surface of the knee that contacts the saddle is hand-scraped, creating surface pockets that allow lubricants to stay in place longer. The saddle travel on a Series I Bridgeport mill is 12”.

Worktable

The table sits on top of the saddle and moves along the X-axis (left to right), either by turning one of the handwheels on each end of the table or engaging the power feed if the machine has one. Like other moving parts on the machine, the table has a locking lever to minimize vibrations. T-slots machined into the table’s surface aid in clamping workpieces or vises for machining. The Series I standard mill has a table size of 9” x 49” and a table travel of 35.5”.

Turret

The turret sits atop the column and connects it with the ram. Because the turret rotates by loosening up a series of nuts, the cutting head can access otherwise hard-to-reach areas on the worktable. Some mills have a protractor marking on the turret, allowing precise positioning along the worktable.

Ram

The Bridgeport’s ram is locked into the dovetail assembly on top of the turret. A rack and pinion mechanism and a crank allow ram travel of 12” in and out, while a large hole on the back of the ram allows for mounting attachments. And because the ram is on a turret, the operator can swing the attachment 180 degrees and use it above the worktable.

Head

The head houses the spindle and the quill. The original Bridgeport mill has a C Head, but the J Head is standard on most Bridgeport mills. The spindle speed range varies depending on the head and motor attached to the machine. Operators can swivel the head 90 degrees left or right and 45 degrees up or down. The tilt joints have protractors to use as a reference for precisely tilting.

Quill

The quill is a unique feature on a Bridgeport mill, enabling it to act as a drill press by moving the spindle up and down using the quill feed handle. The quill travel is 5” and the quill diameter is 3.375. For boring operations, operators can raise and lower the quill slowly the quill handwheel to raise and lower the quill slowly or use an optional power quill feed. The drilling capacity in mild steel is 1.25” using manual feed and .75” with power feed.

4. Adding Enhanced Accuracy to a Bridgeport Mill

Digital readouts (DRO) from manufacturers like ACU-RITE and Newall make the manually-operated Bridgeport machines help improve productivity and increase the quality of a machined workpiece. An LCD indicates the axis positions, typically the X-axis and Y-axis, but 3-axis models also show the Z-axis position. DROs often come with new Bridgeport mills, but these units can be retrofitted on an older machine.

5. Applications of a Bridgeport Mill

Bridgeport mills are typically the most versatile machines in a machine shop. The rotating turret, movable ram, Z-axis movement from the knee and quill, and tilting head allow machinists to cut almost anything: milling, facing, drilling, tapping, boring, reaming, and angle cuts are some of the standard applications of a Bridgeport mill.

Even though Bridgeport mills have a relatively small footprint, they have a well-earned reputation for rigidity. Machinists can take deep cuts in tough materials on Bridgeports weighing only 2,000 pounds. The reason? Bridgeport mills are manufactured with a solid cast iron frame with excellent vibration-damping qualities that withstand the vibrations and impact of heavy cuts.

As a result, Bridgeport milling machines machine flat or irregularly shaped surfaces with larger face mills and cut gears or slots using smaller end mills. With a drill chuck or R8 collet in the spindle, it’s possible to drill, tap, bore, and ream quickly if the machine has a variable speed head. These machines are so well-made that it’s possible to broach keyways without fear of damaging them.

6. What is the Difference Between a Bridgeport Mill and Other Mills?

Every milling machine removes material from a workpiece by rotating a cutting tool and feeding (moving) it into the workpiece. Although there are several types of milling machines, they are usually differentiated as knee-type and bed-type.

Although you can mill, drill, bore, and cut slots with either machine, the vertical knee mill is preferred for its versatility and is the most popular milling machine found in most machine shops today. With a knee-type milling machine, the table is mounted on a knee that moves vertically along the column. The knee supports the table and allows for the up and down movement, which is how the machine adjusts the position of the workpiece. The milling head can also be tilted to machine at various angles.

On the other hand, bed-type milling machines feature a fixed table and movable ram, which is the opposite of the knee mill. Bed mills typically have greater load capacity, with a bed mill carrying approximately twice the load of a knee mill. The bed mill’s cutting tool is mounted on a vertical or horizontal spindle moving along the bed to remove material from the workpiece. One advantage bed mills have other lighter machines is their stability, allowing them to handle larger workpieces.

One advantage of a bed-type milling machine is that it provides greater stability and accuracy than other milling machines due to its sturdy construction and the fact that the workpiece is securely clamped to the bed. Bed-type milling machines are available in various sizes and configurations, from small benchtop models to large, floor-standing machines.

Here’s a comparison of the two types and the difference between the two:

- Design: The significant difference between a knee and a bed milling machine is their design. A knee mill has a vertically adjustable knee mounted on a column attached to the bed, and the worktable is mounted on the knee and moves along the Z-axis. In contrast, bed mills have a fixed bed to support the worktable and the cutting tool, and the spindle head moves along the bed to perform the machining.

- Size and capacity: Bed mills are more potent than knee mills. They are designed to handle larger and heavier workpieces, while knee milling machines are typically suitable for small to medium-sized workpieces.

- Accuracy and precision: Both types of mills offer excellent accuracy and precision.

- Versatility: Bridgeport milling machines are more versatile since the adjustable knee enables a greater range of cutting operations. Knee mills are ideal for small- to medium-sized machine shops, home workshops, and general-purpose milling operations.

7. Should I Buy a Bridgeport Mill?

The answer will depend on your specific applications and floor space.

These are the advantages of a Bridgeport knee mill:

- They have a smaller footprint and fit comfortably in the corner of most shops

- They are high-speed, productive milling machines that need no programming

- They are easy to learn and operate

- Perfect for secondary operations such as drilling, tapping, and simple primary machining operations

- One more advantage if your Bridgeport has a power drawbar for faster tool changes and coolant for specific metals

Remember that a step pulley design is cheaper and easier to repair but time-consuming if you want to be productive.

8. How Much do Bridgeport Mills Cost?

A new Bridgeport Series I standard package includes an R-8 spindle, chrome ways and gibs, and one-shot lube and sells for $19,600. Add a 12-piece collet set with R-8 spindle taper for $642.

9. Are Bridgeport Mills Still Made?

Yes. However, they are now produced by Hardinge, Inc. and they will now manufacture the Bridgeport mills in the company’s Elmira, New York facility.

10. Who Makes the Best Bridgeport Style Mills?

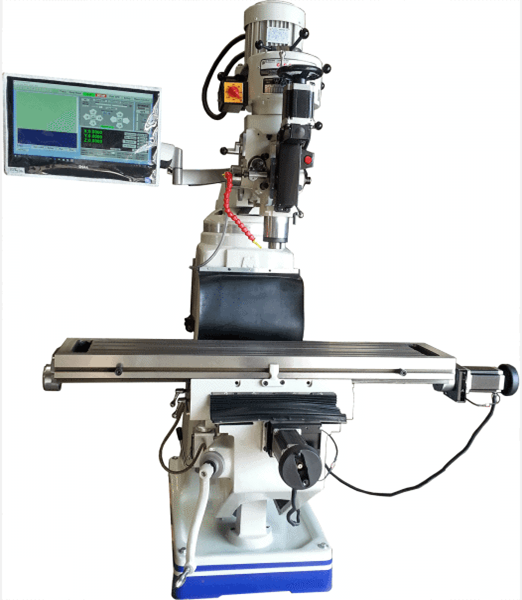

CNC Masters, an American company, offers its Supra 9 x 49 vertical knee mill as a classic Bridgeport-type milling machine with CNC technology on a 9″ x 49″ table size. Like the original, it features heavy-duty construction and space-saving design and is easy to learn and operate. The big difference is in the CNC control with full three-axis interpolated movement with computer variable spindle control.

The Supra 9 x 49 mill handles maximum travel of 34” x 11.5” on the X and Y axes, while the Z-axis (spindle axis) is quill driven for accuracy. The best news is that these can switch to manual control and back to CNC control faster than you can say: These must be expensive machine tools! The new Bridgeport manual machine sells for $19,600, while a brand new American-made Supra—capable of CNC and manual control—starts at under $13,000!

Why wait? Talk to one of our experts at CNC Masters, and we’ll fit you with a CNC mill to increase your production immediately. Please fill out our contact form today!