CNC router machines have emerged as a game-changer in the dynamic manufacturing and design world. These versatile machines, employing the precision of computer-controlled cutting, are opening up new possibilities across various industries. From carving complex patterns to crafting furniture with absolute accuracy, a CNC router is the ideal blend of technology and creativity. In this guide, we delve deeper into the critical features of CNC routers, showcasing their capabilities and exploring how they are revolutionizing the manufacturing landscape.

But first, here is a brief look at these CNC machines to help you determine if they are right for you.

What is a 4X8 CNC Router?

A CNC router is a computer-controlled cutting machine used for machining various materials including wood, metal, plastics, acrylic, MDF, and foams. It’s a vital tool in many industries, particularly manufacturing, where precision and efficiency are paramount. The machine operates on the Cartesian coordinate system (X-axis, Y-axis, and Z-axis), allowing three-dimensional cutting and milling.

The 4×8 CNC router has a cutting area that is 4 feet wide by 8 feet long. The 4×8 is on the medium/large size for routers. Its size means it can handle full sheets of wood like plywood, which makes it perfect for woodworking. Some routers, referred to as desktop/tabletop routers, come in smaller sizes, while other routers are much larger still.

It is programmed with a set of specific commands, or G-codes, which control the cutting and movement of the machine. The precision of a CNC router ensures repeatability, allowing for the same design to be cut or milled multiple times with negligible variation. This makes them indispensable in large-scale production where consistency is essential. Moreover, CNC routers can also be used for intricate and detailed work in smaller settings, such as woodworking shops, due to the flexibility provided by their control software.

Which Industries Use CNC Routers?

CNC routers are extensively used across multiple industries due to their high precision and efficiency. The woodworking industry, for example, utilizes CNC routers for intricate carving, engraving, and cutting tasks, while the metal industry uses them for their precision in metal fabrication. CNC routers offer precise shaping and cutting of materials in the plastics industry, while signage companies also utilize them for creating detailed and complex signs. Additionally, CNC routers find applications in foam industries for cutting various foam materials and in the arts and crafts sector for creating intricate designs and patterns.

Which Features Do the Best CNC Routers Offer?

Computer Numerical Control (CNC) routers are revolutionizing the manufacturing and woodworking industries with precision, versatility, and efficiency. With features ranging from intricate carving capabilities to high-speed automated routing, these machines deliver exceptional accuracy, often unattainable with manual operations. Let’s look at the top features of CNC routers that make them an invaluable asset in modern production environments.

1. Automatic Tool Changer

Automatic tool changers (ATCs) are critical components of modern CNC routers, enhancing their versatility and efficiency. ATCs vary in design, but their primary function is to enable the CNC router to switch between a variety of tools in a quick, automated manner. This capability significantly reduces machine downtime associated with manual tool changes, thereby increasing productivity. Moreover, ATCs facilitate precision and repeatability in machining complex parts, thereby maintaining high-quality standards. With the integration of ATCs, CNC routers become more adaptable and capable of efficiently handling complex, multi-step machining tasks.

2. Steel Frame for Durability

Steel frame construction is paramount for CNC routers, providing stability, durability, and precision. The rigidity of the steel frame ensures that the machine can withstand high-intensity operations without deformation, maintaining an accurate routing path over time. This feature translates to consistent, high-quality outputs even in demanding work environments. Remember, steel’s inherent longevity affords a longer lifespan to the machine, yielding a higher return on investment.

3. A Table Top Matching Your Requirements

One can use several types of tables with CNC routers, each with distinct advantages for particular applications:

- The most common type is the T-slot table, which allows for easily adjustable clamping to hold workpieces of varying sizes.

- Vacuum tables, on the other hand, use suction to hold materials in place, especially useful for thin, lightweight materials that might otherwise shift during cutting. These tables should come with valves, plumbing, and a vacuum pump.

- Perforated tables utilize a series of small holes to create a secure mount for workpieces using vacuum or mechanical hold-downs.

Understanding the capabilities of each type of table is crucial to maximizing the efficiency and precision of your CNC routing tasks.

4. Sufficient Work Area

Most full-size CNC routers feature 48″ x 96″ table sizes. However, they offer substantial table sizes such as 120″ x 240″ or even more significant for larger commercial and industrial applications. These measurements can handle large sheet materials, making them ideal for extensive production operations.

5. Servo vs. Stepper Motor

Servo motors have several advantages that make them better suited for CNC routers. For starters, they offer higher precision and accuracy in their movements, owing to their feedback loop that provides real-time adjustments and reduces the risk of errors. Servo motors also offer superior speed control, essential in CNC routing applications where maintaining a consistent speed is critical. Additionally, they have a higher torque-to-inertia ratio, allowing for quicker start and stop. They can hold their torque even at lower speeds, ensuring the CNC router operates efficiently across various speeds.

Alternatively, the NEMA23/34 stepper motor is vital in automation and robotics. It has superior torque, precision, and durability. The designation “NEMA23 and NEMA 34” refers to the motor’s faceplate dimensions, making it adaptable to various applications. This stepper motor is prevalent in CNC machining for its ability to perform intricate movements with extraordinary accuracy.

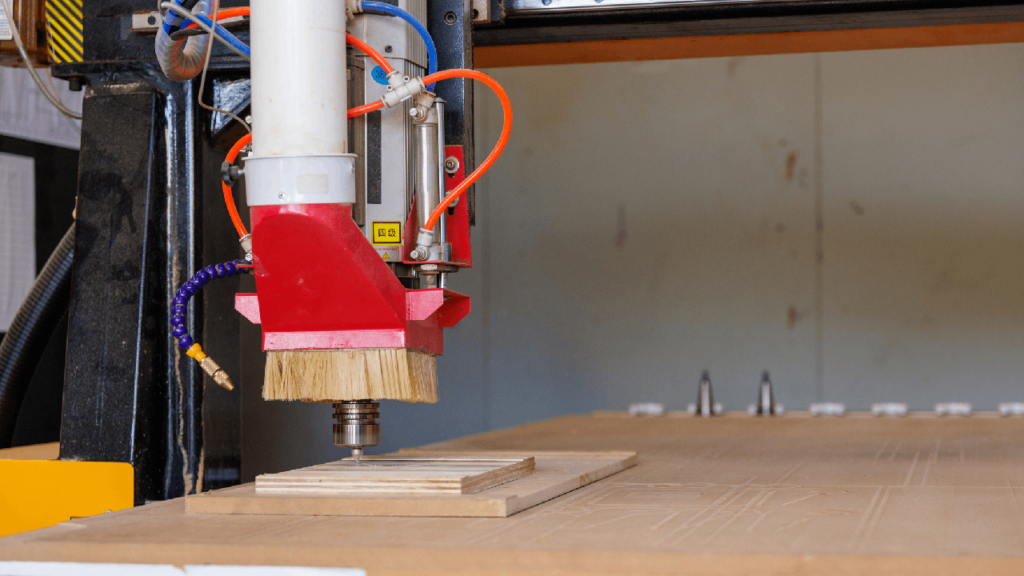

6. Dust Collection System

Dust collection systems for CNC routers are essential. As these machines cut, carve, and shape materials, they inevitably produce dust and waste. Without an effective dust management system, these particles can accumulate, leading to operational inefficiencies and potential health risks for workers. A dust collection system effectively captures and removes these particles, ensuring the cleanliness and safety of the work environment.

7. Ball Screw Drive System

Ball screws are optimal for CNC routers due to their efficiency and precision. They operate on the principle of rolling contact, resulting in significantly less friction than rack-and-pinion drives, leading to higher mechanical efficiency. Ball screws require less energy to deliver a specific force, reducing power consumption. Furthermore, they provide smooth, backlash-free motion and excellent positioning accuracy, vital characteristics in CNC machining. The wear and tear on ball screws is also lower, making them more durable and ensuring a longer lifespan for the CNC router.

8. Safety Features

CNC routers need to incorporate several safety features to ensure their safe operation. An emergency stop button should be easily accessible, enabling operators to immediately halt machine functions in case of any potential hazards or malfunctions. Additionally, the machine should include protective shields to prevent accidental contact with the cutting tool, which can cause serious harm. Dust extraction systems are also critical to maintaining a safe and clean work environment, reducing the risk of respiratory problems. Also, advanced CNC routers should come with software to detect potential design errors before execution, reducing the risk of damaging the machine or workpiece. Finally, proper grounding and insulation protect users from electrical shocks.

9. Heavy-Duty Gantry

Heavy-duty gantries are crucial in CNC routers, contributing significantly to their efficiency and precision. Specifically, they support the cutting tools, ensuring smooth and accurate movement across the working surface. The robustness of a heavy-duty gantry enables it to withstand high levels of vibration and stress experienced during the routing process. Minimizing vibration enhances the output quality and extends the lifespan of the CNC router, making it a cost-effective investment for businesses involved in industrial manufacturing.

10. Electrical Requirements

A CNC router necessitates a robust and reliable electrical setup to function optimally. Typically, these machines operate on single-phase or three-phase power, with the requirement depending on the machine’s size and design. Although many small to medium-sized routers will run efficiently on single-phase power, usually requiring 110-220 volts, industrial-grade CNC routers often demand three-phase power setups and 220-440 volts. These machines also need a stable power supply, as fluctuations can cause performance issues or damage the electrical components. Therefore, it is crucial to account for the CNC router’s electrical requirements during the planning and installation to ensure safe and efficient operation.

11. Variable Speed, Liquid-Cooled Spindle Motor

Variable-speed, liquid-cooled spindles bring significant advantages to the operation of CNC routers:

- They offer a broad range of speeds, allowing for optimal tooling performance across varied materials and tasks, resulting in improved accuracy and quality of work.

- The variable speed function can enhance the tool’s life by reducing wear and tear.

- The liquid cooling system minimizes heat build-up, a vital factor in maintaining the spindle’s longevity and ensuring consistent output.

It helps maintain the spindle’s stability, reducing the chances of deformation and resulting in more precise machining. By mitigating the impact of heat, it allows the CNC router to function for extended periods without downtime, thus boosting productivity.

12. Plug and Play NEMA 34 CNC Control System

The Plug and Play NEMA 34 CNC Control System is a revolution in CNC routers. This system embodies a seamless blend of power and precision, delivering robust performance for various routing tasks. Its user-friendly interface facilitates an easy setup process, significantly reducing the learning curve for hobbyists and DIY operators. The system harnesses the power of NEMA 34 stepper motors, known for their high torque capabilities, ensuring excellent control and accuracy even under demanding routing conditions. This plug-and-play system truly simplifies the operations of CNC routers, making it an indispensable tool for novices and professionals.

13. CAD/CAM Software

CAD/CAM software in CNC routers has modernized the manufacturing industry by offering enhanced precision and efficiency. CAD (Computer-Aided Design) allows for detailed 3D modeling of products, enabling designers to visualize and tweak designs before manufacturing. On the other hand, CAM (Computer-Aided Manufacturing) takes the CAD designs and converts them into machine-readable instructions, automating the control of CNC (Computer Numerical Control) machines. Look for brand names like VCarve Pro and Vectric as you research the software.

CNC Router Machines vs CNC Mills

CNC routers and CNC milling machines, while both being computer numerically controlled (CNC) machines, serve different purposes and are used in varying applications. CNC routers are typically used in large-scale applications, including sheet material cutting and carvings. As mentioned, they are ideal for cutting softer materials like wood and plastic, and routers run at higher travel speeds, measured in inches-per-minute (IPM). They can handle larger sheets on their 4’ x 8’ table tops, making them popular in the sign-making and furniture design industries.

Conversely, CNC milling machines are commonly employed in jobs requiring more strength and precision. Milling machines can handle more rigid materials, such as steel and titanium, and are used to produce machine parts, tools, and intricate designs. Their heavy-duty construction, higher torque, and increased rigidity allow for precise, heavy-duty cutting. Milling machines are prevalent in industries such as aerospace and automotive, where precision is paramount.

Routers and milling machines, while both used in manufacturing and woodworking, employ different types of cutting tools. Routers typically use a rotary tool called a router bit, which allows diverse shapes and designs to be cut into the workpiece. Milling machines also use various cutting tools depending on the task at hand, including end mills and face mills. Unlike router bits, these tools can cut in multiple directions and are typically used for heavier-duty milling operations.

Remember your application when choosing between a 4’ x 8’ router and a large mill. The router was designed to comfortably handle a full sheet of plywood and spoil board. Most mills cannot!

Additional Considerations

As you shop for a CNC router, keep your budget in mind.

The cost of a full-size CNC router can vary significantly based on its specifications, capabilities, and the manufacturer. A basic model, primarily used for hobbyist or educational purposes, may start at $5,000 – $10,000. However, industrial-grade CNC routers with advanced features for precision manufacturing can cost anywhere from $30,000 to $150,000 or more. These high-end models typically offer superior accuracy, speed, and durability, making them well-suited for heavy-duty operations in the automotive, furniture, and aerospace sectors. It’s important to note that additional costs may also accrue from maintenance, software upgrades, and tooling requirements.

Check the machine’s warranty and spec sheet to ensure everything you need from the machine is included there. Finally, confirm where your machine was manufactured. If “Made in the USA” is important, verify that your machine was made here!