Whatever your motion control applications, choosing a suitable motor is essential for its efficiency and productivity. It can be challenging to pick between stepper and servo motors since several factors come into play: among the most important are speed control, positional accuracy, and being cost-effective.

You can make the decision easier by first understanding the differences between the two motors, including their pros and cons, and aligning the motor’s capabilities with your application’s requirements.

Since both motors are used extensively in manufacturing equipment, we will look carefully at each motor to help you determine the right one for you.

What is a Stepper Motor?

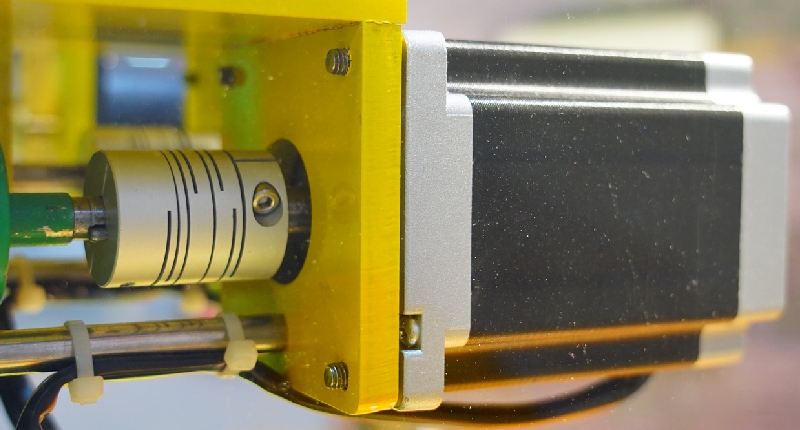

A stepper motor is a brushless synchronous DC motor consisting of a rotor with permanent magnets and a stationary stator carrying the windings. A current runs through the windings, generating a magnetic field that interacts with the rotor’s magnetic field, creating a turning force. Stepper motors have high pole counts, and each is energized in sequence, so the rotor turns in a series of steps that appear as continuous motion.

Stepper motors have several advantages, including running an open-loop system, which eliminates the cost and complexity of an encoder. The stepper’s high pole count allows it to generate high torques at zero speed, and they are typically compact and less expensive.

Unfortunately, this type of motor has speed limitations, meaning they run best at 1,200 rpm or lower. They generate high torques at zero speed, but torque decreases at higher speeds. A motor generating 100 oz-in at zero speed might only deliver 50 oz-in at 500 rpm and a mere ten oz-in at 1,000 rpm.

Adding a gearbox could provide higher torque, but the stepper’s low speed would be an issue. Adding a 10:1 gear reducer to a 1,200-rpm stepper motor could boost the torque, but it will also drop the speed to 120 rpm. If the motor drives a ball-screw actuator or something similar, it likely will not provide enough speed for the application requirements.

Stepper Motor Applications

Stepper motors provide excellent performance economically for applications requiring low speed, acceleration, and positioning accuracy. Common examples include XY positioning on machine tables or production line conveyor machinery that must advance at a constant rate.

Care is required to avoid vibration from the drive motor damaging the components when transporting circuit boards, semiconductors, or other precision components along a conveyor line. Micro-stepping techniques minimize vibration from the stepper motor to prevent this, ensuring the smooth movements of precision components.

Stepper motors can also drive the hands and joints of industrial robots. As movement precision and flexibility improvements are achieved by attaching a rotary encoder to the stepper motor, it will play an essential role in the field of robotics.

What are the Pros and Cons of Stepper Motors?

Pros

A stepper motor provides a simple design with excellent low-speed torque and smoothness. It offers less power consumption at zero speed, open-loop positioning, and repeatability, and does not require position feedback, lowering its overall costs and making it a popular choice. All in all, stepper motors are a versatile, reliable, cost-effective, and accurate way to control precise movements and increase the dexterity and efficiency of programmed movements over various applications.

Cons

On the downside, stepper motors have some limitations. They lose most of their torque as the speed increases, sometimes as much as 80%, and they create high vibration levels and are prone to resonance issues. Stepper motors also produce high heat and maintain a constant current regardless of requirements. Finally, the motors cannot respond to changes in load.

What is a Servo Motor?

The primary difference between the two motors is in the overall pole count. While stepper motors have a high pole count—typically between 50 and 100—servo motors have a pole count between 4 and 12. The difference in pole count means that stepper motors move incrementally (in steps) with a consistent pulse in an open-loop system.

Servo motors require an encoder to adjust pulses for position control, and because they have significantly fewer poles, they must run under closed-loop control. As a rule, servo motors run at high speeds of several thousand rpm and with gearboxes for higher torque at valuable speeds. They also deliver consistent torque control across the motor’s speed range.

Unlike stepper motors, servos do not have holding torques. However, closed-loop servo control commands the load to remain at a specific position. The motor makes continual adjustments to keep it there, amounting to a de facto holding torque.

Servo motors often use expensive rare-earth magnets to help them generate more torque in smaller packages. Their larger size also gives them a torque advantage, with servo motor diameters ranging from NEMA 17 to 220 mm. Combining these factors, servo motors can supply torques up to 250 ft-lb.

Servo motors have the speed and torque for higher accelerations while delivering more accurate positioning, thanks to the closed-loop system. Servo motors can also provide peak torque briefly to overcome variations in load and higher motor acceleration.

Servo Motor Applications

Servo motors provide precise motion control for CNC milling machines, lathes, grinders, and other equipment used in metal fabrication. Servos are also used in automation, specifically in robotics, where a servo motor at each robot arm joint can actuate movements and give it a precise angle. They also have applications in food services, pharmaceutics, and the in-line manufacturing process.

Servo motors are utilized in everyday items such as electronic devices like DVD and Blu-ray Disc players, where servos help to extract and retract disc trays. Automobiles also use servo motors to control their speed by sending electrical signals to the car’s computer for processing and onto a servo attached to the car’s throttle to adjust the engine speed. Servos even control motion in commercial aircraft.

Servos play a role in today’s toys, such as remote-controlled toy cars, airplanes, helicopters, and robots. They also position control surfaces for radio-controlled planes and electrically operated machinery, including elevators, rudders, walking robots, and working grippers, which use servo motors.

What are the Pros and Cons of Servo Motors?

Pros

Three-phase AC servo motors use rare earth permanent magnets, offering excellent torque density and advanced algorithms. A servo uses position feedback to control the motor’s position, speed, or torque, and if a heavy load is placed on the motor, the driver will increase the current to the motor coil as it rotates the motor. And because of its precision, a servo allows companies to operate it faster. Servo motors run at lower temperatures and are a better choice for variable-load systems.

Cons

Although servo motors offer convenience and efficiency, they tend to inflict high operating and maintenance costs. Adding the cost of position feedback, an encoder, and perhaps a gearbox, the motion system becomes even costlier. Remember that the need for an encoder and gearbox makes the system more mechanically complex, resulting in more frequent maintenance and higher costs.

Which is Better: Stepper or Servo Motors?

No simple answer exists to which motor is better, except to reply, “It depends.” A lot hinges on your requirement, so choose a stepper motor if your application meets any of the following criteria:

- Low speed and high accuracy

- Short, rapid repetitive movements

- High torque and low speed

- You prefer simple control

Steppers have the advantages of lower system costs, minimum system tuning, low maintenance, and rugged construction.

Go with a servo motor if your application meets any of these requirements:

- Control of the applied force

- Requirements for high speeds

- Dynamic motion profiles

Servos execute complex motion commands, control torque, and adjust to load changes, giving them a significant performance advantage. However, steppers don’t need feedback, use less expensive magnets, and rarely have gearboxes. In terms of repeatability, stepper motors are competitive. Their high pole counts and ability to generate holding torque while consuming less power at zero speed make them a favorite of manufacturers working within a budget.

This adds up to steppers being less expensive than comparable servo motors.

The bottom line: If costs are a priority and the application is lenient, stepper motors will do the job. If performance is the overriding consideration, servo motors will also do the job—but at a much higher cost!