Nothing beats the impressive power of a freestanding industrial lathe. Larger models can occupy an entire room and handle parts with dimensions measured in feet, not inches. But while full-sized lathes are incredibly powerful, they aren’t usually suited for small toolroom work or the DIY projects in the home workshop.

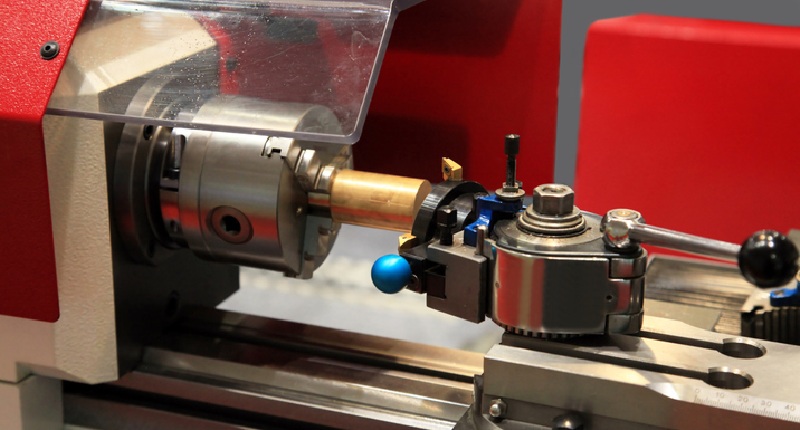

Here’s where the benchtop CNC lathe works better. Desktop or benchtop lathes are more compact versions of freestanding industrial lathes. Despite being smaller, desktop CNC lathes can perform as many functions as the larger models. They’re equipped with powerful built-in control technology, and they typically feature the same components used in the bigger machines.

Smaller doesn’t mean more delicate: high-quality benchtop CNC machine tools feature the cast-iron columns and rigid construction of large lathes or milling machines. All the components of a desktop lathe, especially a metal lathe, must be heavy-duty and stand up to wear and tear. Like its larger counterparts, a desktop CNC lathe must support and display CAM files and converted DXF files.

What is a desktop CNC machine?

CNC controls allow an operator to automate much of the machining process. Computer Numerical Control relies on computer programming in a machine language known as g-code, enabling the programmer to deliver precise instructions. CNC can be integrated with all categories of machine tools, from turning centers to CNC mills.

Desktop CNC machines are smaller versions of their industrial counterparts, and these machines are designed to offer the same power and precision in a more comprehensive package. That makes desktop or benchtop machines ideal for small machine shops or even home workshops, where CNC precision can be applied to smaller workpieces.

Common CNC machine tools

CNC technology applies equally well to several different materials. Woodworking and metalworking shops use CNC milling machines, routers, and CNC turning machines (lathes) to cut everything from steel to PVC and carbon fiber.

Most CNC machine tools share common characteristics: programmable machine controls, a bed to support the workpiece, jaw chucks to mount the workpiece, and movement along multiple axes. That includes at least the X-axis and Y-axis, although machines with a minimum of 3-axis movement (including the Z-axis) are common.

Some of the most common tools for CNC machining are lathes–woodworking and metalworking.

Basics of a CNC desktop lathe

Nearly all lathes employ the same principles. Sometimes, the workpiece is mounted between the headstock and the tailstock. Other times the workpiece is held in a chuck or collet. As the workpiece rotates rapidly, a cutting tool is brought into contact with the workpiece, removing material and shaping it into the correct pattern.

Even small CNC machines are capable of high degrees of precision. For example, a desktop CNC lathe with two axes can handle parts up to six inches in diameter and is commonly used for smaller projects like jewelry. These mini CNC lathes are also used for small parts fabrication or prototyping in R&D labs, and they’re also perfectly at home in a hobbyist’s workshop.

Lathes rely on simple mechanical processes to remove material, but that doesn’t mean they aren’t capable of highly detailed work.

What can I make with a desktop CNC lathe?

Desktop CNC lathes are great for learning how to apply basic CNC machining principles to the world of parts manufacturing. You can learn and apply the same CNC commands used in big industrial CNC machines with a CNC desktop lathe. Operating a desktop lathe is a great way to learn the basics of g-code, CNC programming, and even Computer Assisted Design (CAD) and Computer Assisted Machining (CAM) programs.

Skilled operators can craft nearly anything on a high-quality CNC lathe. That includes custom replacement parts for a classic car, threaded screws or custom bolts, or just basic cylinders or shafts.

What are the benefits of a desktop CNC lathe?

Greater accuracy and precision on smaller parts: Smaller machines are often better suited for more delicate or detailed machining. With benchtop lathes, you can achieve precision and accuracy on smaller parts while maintaining control.

Compact but powerful package: Many machinists don’t require a full-sized industrial lathe, but they need something to provide the necessary machining precision without taking up half their workspace.

Easy to learn: Learning to use a benchtop CNC lathe is getting easier all the time. While no CNC lathe is exactly simple, enhancements like CAD/CAM and conversational language have made CNC lathes quite a bit easier to learn.

Easy to use: CNC machines don’t require a lot of human intervention once the programming code has been loaded. The operator needs to change the workpiece, check a few dimensions, replace cutting inserts, and make any other needed tooling changes.

Budget-friendly: Industrial CNC lathes can be extremely expensive, with a single machine running into the tens or hundreds of thousands of dollars. Desktop CNC lathes are available from reliable manufacturers like CNC Masters for far less.

Smaller footprint: Desktop CNC machines don’t require as much space, and they are the ideal solution for smaller companies that don’t have a lot of room but still require the features of a CNC machine.

Safer operation: CNC machines are safer than manual machines because the operator is not as close to the machining and might even be behind a guard or transparent safety door.

What are the desired features of a CNC desktop lathe?

Look for the following:

- High-speed spindles

- Variable spindle speed settings

- Live tooling control

- Collet chuck

- Threading guides

- Advanced coolant systems

- Extended warranty

- Stepper motor driver with 2-axis interpolation capability

- Large swing over bed to offer a substantial working area

- Quick-change tool post with multiple tool holders

- 3-HP spindle motor

Benchtop CNC Mills from CNC Masters

CNC Masters also offers three high-precision benchtop mills, suitable for advanced hobbyists and full-function machine shops.

The CNC Jr Table Top Mill packs all the features of a mid-sized CNC milling machine in a compact package. The smallest of the CNC Masters CNC machine tools, the Jr. still weighs an impressive 700 lbs., thanks to solid cast-iron construction. That’s enough weight to provide much-needed stability and ensure accurate cuts.

CNC Masters’ Baron Table Top Millis a level up, adding another 100 lbs. to the overall weight and taking the precision up another notch. X and Y zero-backlash ball screws keep the machine on track, while micro-stepping motors ensure that the entire cutting process moves smoothly.

Top of the line is the CNC Max Table Top Mill. With the potential for 4-axis cuts, the CNC Max is an incredibly powerful machine tool at home in nearly any situation.

Each desktop CNC mill and CNC lathe from CNC Masters comes with complete technical support services

If you’ve thought about investing in a CNC machine in the past but lack the room or resources for a large freestanding unit, a desktop model is a great option to consider. At CNC Masters, we can work with you to help you find a machine that suits your unique needs.

We offer a diverse selection of CNC lathes and milling machines that can be used for various applications. Our CNC lathes are crafted in the United States, and their quality is 100% ensured. No matter your situation, if you’re in the market for an affordable CNC with high performance, our desktop machines are a great option.

Master MX Software Program is included with every desktop CNC machine

Try out the new Master MX. The MX works exclusively with the CNC Masters MX Numerical Control Units now being built with our CNC milling and lathe machines. The MX software is included with your CNC Masters Machine.

You can import FANUC-based G code and M code programs from your CAM software. We also offer Visualmill CAM as an option which comes with a guaranteed post processor made for CNC Masters machinery.

At CNC Masters, we have been providing high-quality CNC mills, milling machines, and CNC lathes for 20 years. Business owners, machinists, scientists, researchers, teachers, and even hobbyists have discovered our California-based company’s superior quality, competitive prices, and professional service.

Call us at 626-962-9300 or email us at sales@cncmasters.com. Better yet, call us for an appointment and visit our facility in Irwindale, CA.