If you’re reading this article, there’s a good chance you are already familiar with at least some of the equipment that populates most fabrication and machine shops, the two primary machines being the milling machine and the metal working lathe. You also probably know that these machine tools are available in a traditional manual model and as a CNC machine.

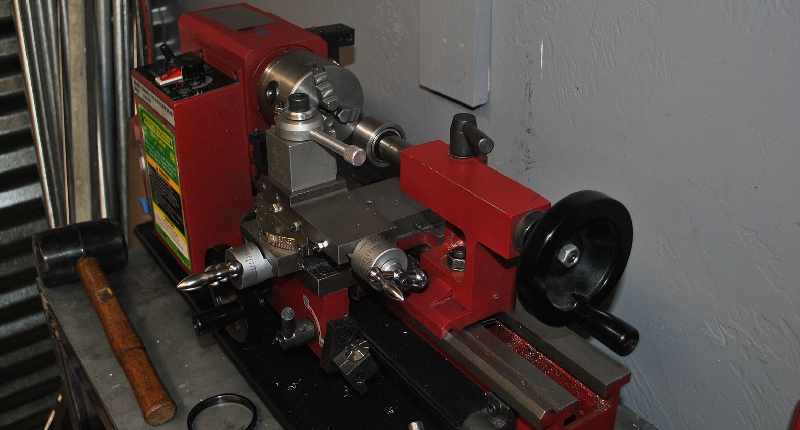

However, you might have yet to realize that these machines can be purchased as benchtop models, so named because they fit on a workbench like one of your drill presses. These smaller versions offer plenty of advantages for home hobbyists and DIY enthusiasts and serious machinists looking to make money from them.

Let’s take a look at one of these benchtop models, the mini metal lathe, to discover what they are, their practical uses, features, and pricing.

What is a Mini-Lathe?

A mini metal lathe can be defined as any benchtop lathe with a distance of 20 inches or less between the lathe chuck and tailstock (sometimes called “between centers”) and 12 inches or less of swing over the bed. (Swing is the largest workpiece diameter you can turn on a mini lathe machine).

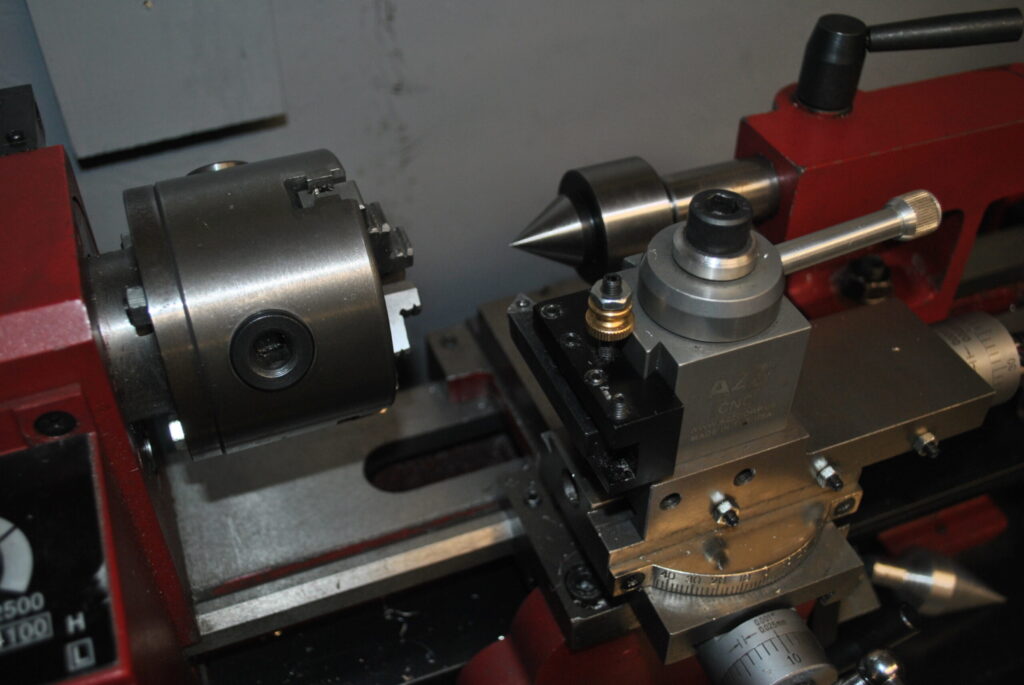

Usually, a mini lathe has a 1/2 to 3/4 HP motor and a 1.0” to 1.5” spindle bore diameter. A mini metal lathe can weigh as little as 10 pounds or as much as 150 pounds. However, they have all the components of a full-size lathe, including a tool post, lathe chuck, cross slide, centers, steady rest, and tool holder.

A mini-lathe uses the same tooling, such as carbide and high-speed steel (HSS) lathe tools, parting (cutoff) tools, turning tools, and threading tools. And a workbench model can perform many of the same operations as a larger lathe, with the workpiece size being the main limitation.

What is the Difference Between a Mini-Lathe and a Full-Sized Lathe?

The primary differences between the traditional lathe and the mini-lathe are size and price. Benchtop lathes take up much less space, fitting into out-of-the-way corners or on top of a workbench. Its size means the mini-lathe does not take up critical floor space, a significant advantage for those working in garages, home workshops, and small facilities.

Mini lathes are affordable, with prices as low as a few thousand dollars, while even used metal turning lathes are in the tens of thousands, with new CNC machines costing hundreds of thousands.

On the other hand, full-size lathes can handle longer and heavier workpieces requiring bigger diameters. Because they weigh thousands instead of hundreds of pounds, they can take deeper cuts without vibrations, making them more productive. However, many mini-lathes can be lifted by a couple of works, giving them portability that the big lathes don’t have.

What are the Mini-Lathe’s Benefits?

- The cost is a fraction of a full-sized lathe

- Replacement parts and upgrade parts are considerably less expensive than bigger models

- Most precision mini lathes have variable speed control

- Producing tiny parts on a mini lathe is less cumbersome than on a big lathe

- They work equally well for metal turning or wood turning

- Variable spindle speeds range from 50 to 2,500 RPMs

- Modest power requirements, as most mini lathes work on 110V

- Many benchtop models are CNC lathes

- CNC lathes used for woodworking can eliminate the hand-cutting tools and chisels used in manual lathes

- High-speed mini lathes are ideal for polishing and sanding operations

- Thread indicators on many mini lathes help lathe operators turn screw threads from 12 to 52 TPI in either metric or imperial

- Most mini lathe tooling packages include quick-change tool posts for convenience and higher productivity on wood lathes and mini metal lathes

- Mini lathes often offer powerful brushless motors

Features to Look for When Shopping for a Mini-Lathe

As you search for the ideal mini lathe, keep reminding yourself how you will use it. For instance, if you’re turning the ends on long bars, ensure they fit completely through the machine. Many spindle bores are .85” in diameter, meaning a 1” diameter will not fit through.

If you’re looking for a versatile machine that can machine metals, wood, glass, and plastic, be sure the lathe has a high-quality cast iron bed with standard nylon gears and bushings. Metal gears would be an excellent upgrade.

Your package should also include a self-centering 3-jaw chuck to accommodate various workpiece configurations for most turning and cutting operations, an MT3 dead center, and an MT2 tailstock taper.

Check the motor. Most mini lathes are either 1/2 or 3/4 HP with speeds up to 2500 RPMs, but there are models with 1 HP motors with higher speeds. Since you might be turning some relatively small diameters, you want to make sure your machine provides enough speed and ensure it has a variable-speed motor.

Look for a straightforward design so you’ll immediately be comfortable using it. You want to be making parts, not suffering through a long learning curve.

Some other accessories you may have yet to consider include a chip tray to help keep your work area clean, and a set of service wrenches for working on your machine.

What are the Capabilities of a Mini Lathe?

There are virtuously endless possibilities for producing parts on a mini metal lathe. You can probably turn and face most metals up to 2.75″ diameter with a 3-jaw chuck. You can turn a brass piece down to .050” in diameter on smaller parts, drill a tiny hole through it, and use a parting tool to cut it off.

You can work most metals, including aluminum, brass, and steel, on a mini-lathe. With metals such as stainless and with bigger diameters, you’ll need to take smaller cuts, while on non-ferrous metals (aluminum and brass), you can take .040″cuts (.080″ on the diameter) without a problem.

You can also get excellent results from plastics like Delrin, Nylon, Acetal, and Teflon. If you intend to use your machine primarily as a wood lathe, you can check online for dozens of woodworking projects that will fit your benchtop lathe.

How Much Should I Expect to Pay for a Mini Lathe?

Here is an example of a lower-range model from Harbor Freight: the Central Machinery 7 in. x 12 in. Precision Benchtop Mini Lathe runs at two speeds: low running 0 to 1100 RPM and high at 0 to 2500 RPM. It has variable speed control, 3/4 HP, and 12” between centers. The price is $800.00.

On the high end, the Grizzly G9972Z 11″ x 26″ Bench Lathe with Gearbox has a 10” swing over bed, 26” between centers, 1 HP, and a 1” spindle bore for $2,300.

Before you start shopping, be prepared with a list of requirements, so you can quickly narrow down your choices. Be sure to check on the warranty for each machine that meets your qualifications.

Images provided courtesy of HeatSync Labs.