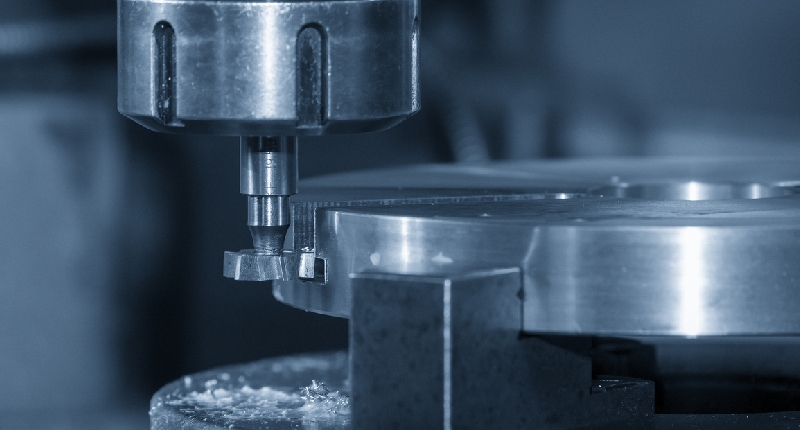

You’ll find a milling machine in nearly every machine shop and manufacturing facility, and the machinists working on them complete an array of cutting operations to produce finished parts. One of the primary reasons for the popularity of the milling process is its ability to remove more material per cut than single-point cutting tools on a lathe machine, shaper, or planer.

The following are fifteen of the milling operations you can expect to perform on one of the many types of milling machines. Although this is not an exhaustive list, it will cover most of them.

1. Face Milling

The face milling operation is one of the simplest. The workpiece’s dimensions determine the size and type of the face mill. The teeth are on the outside and do most of the work, while the cutting edge on the face removes a tiny bit of material of stock left from the springing of the workpiece or cutter, providing a better surface finish.

The facing operation is used only on flat surfaces perpendicular to the axes of the milling cutter. It removes the material by rotating the facing tool in the counterclockwise direction as the table feeds the workpiece across the cutter.

Face milling can be set up on either a vertical or a horizontal milling machine with the cutter mounted on a stub arbor.

2. Plain Milling

Plain milling is another common type of milling machine operation, producing a simple, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor.

An operator sets the depth of cut by cranking the vertical feed screw to raise the table. After determining the correct feed and speed, the table is moved along the X-axis into the rotating cutter to remove material.

3. Side Milling

If you are trying to produce a flat vertical surface in the workpiece, side milling is the option. The side milling cutting tool is fastened to the horizontal arbor, and the table is raised to determine the depth of cut for milling slots or anything with a vertical wall.

Although the side milling cutter’s size, type, and diameter will depend on the machining, you should remember to use the smallest diameter cutter that will work properly and allow for sufficient clearance between the arbor support and workpiece or vise to keep the cutter’s flex to a minimum.

4. Straddle Milling

Straddle milling is used when you must have two or more parallel vertical surfaces machined in one cut. You accomplish this by mounting two side milling cutters on a horizontal milling machine on the same arbor. The cutters are kept apart by a spacing collar that’s the same dimension as the parallel sides so that they “straddle” the workpiece to produce the flat vertical surface.

You can use the straddle milling operation to cut splines, squares, or a hexagon on the end of a round part.

5. Gang Milling

The gang milling operation involves two or more milling cutters secured together on one arbor to machine several surfaces simultaneously. Typically, milling cutters of different diameters, shapes, or widths are mounted on an arbor with spacing collars. The combination of cutters is determined by the requirements of the part and is virtually unlimited.

Gang milling saves machining time and is often used in repetitive work. The cutting speed of a group of cutters is calculated from the cutter with the largest diameter.

6. Angle Milling

The angle milling operation can be accomplished in several different ways: with special form cutters mounted on a horizontal arbor, using end mills ground to the specific angle required, or by tipping the milling machine’s head to the proper angle. The last method is often used on Bridgeport-style vertical knee mills using a straight end mill and side-milling the workpiece.

The angle cutter for the horizontal milling machine could be ground to a double angle for producing parts such as V-blocks.

7. Form Milling

The form milling process allows for machining contours made up of curves and straight lines in a single cut. Formed cutters are ground to the shape of the contour of the workpiece and used on both vertical and horizontal milling machines. Sometimes, the contour will be ground on a single-point fly cutter.

The irregular shapes can be convex, concave, or any other shape and are usually inspected using a template gauge. After machining, the formed surface is checked by a template gauge. Feed rates and spindle speed for form milling are typically 20% to 30% slower than for plain milling.

8. End Milling

End mills are the standard vertical mill cutting tools, producing a vertical, horizontal, or angular flat surface. You can hold end mills in standard holders or collets. (You should only hold single-ended end mills in a collet). The two most common end mills are 2-flute and 4-flute. Most machinists use 2-flute, high-speed steel end mills for aluminum since the flutes are less liable to clog with chips. The 4-flute end mills with reduced cutting speeds are recommended for cutting steels.

End mills are ideal for cutting various slots, grooves, and keyways. End mills can be re-sharpened several times, making them an economical cutting tool.

9. Conventional Milling and Climb Milling Operations

No article on milling operations would be complete without discussing conventional and climb milling. It is essential to understand how the cutting action of a milling cutter changes when the feed direction changes.

Also referred to as up milling, conventional milling is the cutter rotating against the direction of the table feed. Contrast this with climb milling, also called down milling, where the cutter rotates with the direction of the table feed. In one case, the tool tends to climb onto the work, while the other wants to move away from the cut.

Except for light finishing cuts, conventional milling is the safer of the two milling operations.

10. Saw Milling

In this operation, thin cutters make a narrow slot in the workpiece, or they can cut it in two. Feeds and speeds will be slower since rushing the cut could cause the blade-like cutter to break. The workpiece may be held in a vise or clamped directly onto the worktable with the cutter positioned directly over one of the T-slots.

11. Milling Keyways, Grooves, and Slots

Keyways milling operations are made for vertical and horizontal milling machine. Standard keyways are machined on a shaft using a side milling cutter on the horizontal milling machine or an end mill on the vertical mill. Dovetail slots, T-slots, and woodruff key slots require special cutters of the same name, while open slots can be cut with a plain milling cutter, a metal slitting saw, or a side milling cutter mounted on an arbor.

12. Gear Cutting

Gear-cutting operations can be performed using a form cutter mounted on a horizontal arbor or an end mill ground to the proper profile and held in a vertical spindle. The cutter profile fits precisely with the tooth space of the gear, and the equally spaced gear teeth are machined on a gear blank by holding the workpiece on a universal dividing head and indexing it.

13. Thread Milling

Although not used as much as thread turning, machine shops prefer thread milling in specific applications, such as when the threads are against a shoulder, close to the bottom of a blind hole, or they do not want to risk breaking a tap in an expensive part.

The operation is performed with either a single thread or multiple thread milling cutter. It requires three driving motions in the machine: one for the cutter, one for the workpiece, and the third for the longitudinal movement of the cutter.

14. Cam Milling

Cam milling produces cams on a milling machine by using a universal dividing head and a vertical milling attachment. The blank is mounted on the dividing head spindle, while an end mill is held in the milling attachment.

The axis of the cam blank and the end mill spindle should always remain parallel when setting for cam milling. The dividing head is geared to the table feed screw so that the cam rotates around its axis while feeding against the end mill. The axis of the cam can be set from 0 to 90° to the surface of the worktable for the various rises of the cam.

15. CNC Milling

Computer Numerical Control (CNC) milling is a cost-effective way to perform most of the operations on this list (and a few more). CNC mills have become a valuable asset for manufacturers because those processes requiring additional equipment, such as rotary tables and dividing heads, are no longer needed.

Versatile CNC milling machines have boosted productivity, nearly eliminated human error, saved money, and provided safety by enclosing the operation, protecting machinists from flying chips and splashing coolant. These machine tools cannot only take on the most complex milling operations but also drill, bore, ream, and tap without removing the part and completing them as a secondary operation.

Milling Operations are Performed on Several Different Types of Milling Machines

There is also no shortage of cutting tools for the many operations possible on these machine tools, and several different types of mills add to their reputation for versatility. Let’s look at some standard milling machines and the most often used milling cutters before looking at the top 15 machine operations performed on the typical workpiece.

Different Types of Milling Machines

Although milling machines can be categorized into several subsections, the column and knee type machine is the most common. The table is mounted on a knee casting, and the knee is mounted on the vertical slides of the main column. The table moves up and down depending on the size of the workpiece.

- Machines within this category include:

- Vertical milling machine (Manual and CNC milling machines)

- Horizontal milling machine

- Universal milling machines

- Benchtop milling machines (a.k.a. hand milling machines)

Another category includes heavy, rigid machines where the table is mounted on the ways of a fixed bed. The table movement is restricted to the right-to-left direction (X-axis) and in-and-out (Y-axis), with vertical movement (Z-axis) provided by the head. These fixed-bed milling machines are further classified as simplex, duplex, and triplex based on the number of spindle heads.

Types of Milling Cutters

Since no milling operations can happen without a milling cutter, these cutting tools play an essential role in the milling process, and they are used to machine parts on various types of milling machines. Milling cutters are of numerous sizes and shapes, and here are the most recognizable of them:

- Face mill cutters have replaceable carbide inserts with cutting edges on the sides of the cutting head. They are ideal for milling flat surfaces.

- Slab mills are placed on the arbor of a manual horizontal milling machine to machine large surfaces and increase the depth of cut.

- End mill cutters have cutting edges on the end and the circumference of the cutter. End mills work well for small milling operations such as cutting slots and profile milling operations.

- Ball mill cutters are ideal for 3-dimensional milling operations.

- Woodruff cutters have teeth perpendicular to the outside diameter and are used to cut keyways into shafts and other parts.

- Thread mill cutters produce threaded holes, although taps can do that faster.

- Fly cutters are single-point cutting tools that work much like a face mill.

- Angle milling cutters can be in the form of an end mill, or they can fit on an arbor and be used on a horizontal milling machine.

- Formed cutters have irregular profiles on the cutting edges to create irregular shapes such as concave, convex, corner rounding, and gear cutting.

- Dovetail cutters are special cutting tools for machining trapezoidal-shaped grooves (dovetails) into the workpiece. You can also use them to cut angles, undercuts, and deburr parts.

- Helical plain milling cutters have a coarse pitch and a helix angle on the teeth, and it’s helpful in profile milling work.

- Side milling cutters have teeth on the periphery and one or both of its sides. They are typically used on an arbor with the horizontal milling machine, and end mills serve the same purpose on vertical milling machines.

- Sawmilling cutters produce narrow slots or grooves on a workpiece or can be used as a parting tool.

What is the Difference Between a Milling Machine and a Drill Press?

In the not-so-distant past, it was easy to distinguish a milling machine from a drill press by its operations. Milling machines executed one or more of the fifteen operations we will detail below, and drilling machines drilled, tapped, reamed, and bored holes.

However, with the advent of Bridgeport-type vertical knee mills, these versatile machine tools began taking on the operations of a drilling machine and the milling machine operations of a vertical milling machine. And when these knee mills became CNC mills, their capabilities were nearly limitless.

Talk to an Expert in CNC Technology

CNC Masters offers a Bridgeport-type CNC vertical knee mill in two sizes. Called the Supra, our CNC milling machine quickly transitions between manual and CNC milling to perform numerous milling operations. We sell only high-quality, USA-built machine tools with ball screws, a warranty, excellent service, and all at a competitive price!

Please email us directly at sales@cncmasters.com, call us at 626-962-9300, or visit our contact page. You’ll be happy you did!