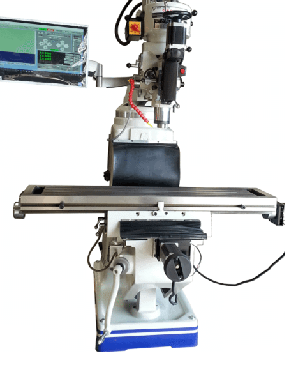

In the past, whenever machinists and machine operators talked about a Bridgeport mill, they were referring to a specific brand: The Bridgeport Milling Machine. However, the manual milling machines were so popular and iconic that the term “Bridgeport mill” was used to describe practically any vertical milling machine, no matter what brand it happened to be.

A Bridgeport is a multipurpose knee mill, having the rigidity and power table feed to be a milling machine and a variable speed head equipped with quill travel for drilling, tapping, and reaming operations. A rotating turret and a sliding ram head added to the milling machine’s versatility.

A Brief History of the Bridgeport Milling Machine

The Bridgeport corporation was founded in Bridgeport, Connecticut, and started selling its machines in the late 1930s. It established its reputation with its medium-sized vertical milling machines, equipped with quill travel and a vari-speed vertical milling head. It became known as a knee mill because of its ram-on-turret mounting over a knee-and-column base.

Who Invented the Bridgeport mill?

Reportedly, a man named Rudolph Bannow came up with the Bridgeport knee mill design in 1936 as the ideal machine on which to mount the milling head that the Bridgeport Pattern and Model Works were already producing. The Bridgeport Series I Standard Knee Mill is the original milling, drilling, and boring machine. The Bridgeport Series I is the most popular mill ever made, with over 370,000 machines built over the past 80-plus years, followed by the larger Bridgeport Series II. Today, Bridgeport milling machines are manufactured by Hardinge.

The Features of the Bridgeport Milling Machine

The Bridgeport table travels on the X-axis (longitudinal), Y-axis (saddle travel), and has a Z-axis on the knee travel and another z-axis with the quill travel. The turret can swivel, while the ram travel allows machinists to cover large areas of any table size. T-slots in the table make it possible to clamp a workpiece or a vise for various types of work.

Many Bridgeports have a power table feed, especially on the X-axis. Some are equipped with an Acu-Rite digital readout (DRO), one-shot lubrication to lube the gibs, a power drawbar, and a variable speed range. The Bridgeport J-Head accepts collets with an R8 spindle taper and a power feed on the quill travel. A mist coolant system can also be added.

CNC Machining Moves Bridgeport-Type Machines off Center Stage

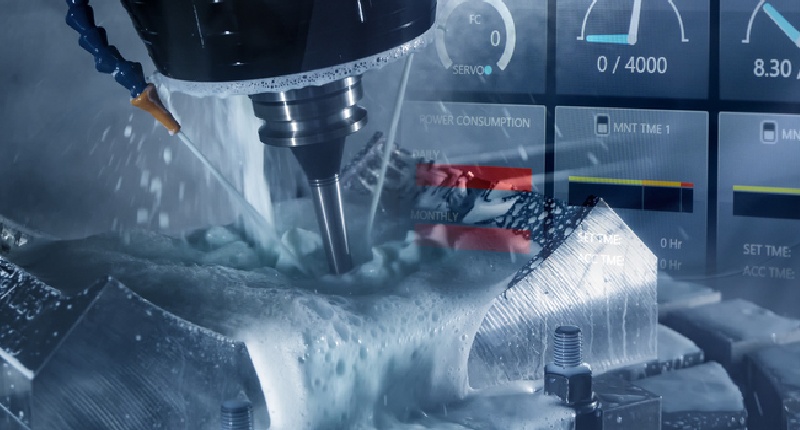

Computer Numerical Control (CNC) refers to directing traditional machines with computer systems. CNC machining grew when computers became widespread in industrial manufacturing processes. Conventional industrial machine tools such as lathes, vertical milling machines, and routers began being operated through computers, giving them more control.

Today, you’ll find that CNC machining in numerous industries supports higher productivity and streamlines the manufacturing process. Here are the primary benefits of CNC machining in manufacturing:

Increased Efficiency

CNC machining offers greater efficiency because computers control the control machine tools. Every operation is automated, spindle speeds are higher, as are feed rates, resulting in a faster turnaround, higher quality, and consistency in production. There is also much less intervention from a human operator running a CNC machine.

Unlike a standard vertical milling machine, CNC machines can sometimes run unattended at night. They don’t need a break unless for maintenance, meaning production does not halt at lunchtime or during scheduled breaks. It’s hard to match that efficiency with a standard Bridgeport mill.

High Levels of Accuracy

Another advantage of CNC machining is consistent quality. CNC machines are programmable, and every detail of the production process goes into the machine. Using CNC machines ensures repeatability and accuracy since human intervention (and mistakes) are no longer a factor.

CNC machines manufacture parts that meet close-tolerance requirements, and fewer errors eliminate waste. CNC machines enable companies to produce parts and products that would otherwise be impossible to make using a standard Bridgeport mill.

Enhanced Worker Safety

Some CNC machines isolate workers and mitigate their risk. Even with Bridgeport-type CNC machines, the operator’s proximity to the cutting tool and flying metal chips is increased to a safer distance. And if changes are required in the part’s design, they are made by adjusting the program at a safe distance.

Human intervention in CNC machining is now mostly limited to a supervisory role, monitoring the programmer’s performance and the software remotely.

In-House CNC Machining is Less Expensive than Subcontracting

If you rely on a third party’s machining centers for your production or complex work, having your own CNC machine will be much more affordable. As it turns out, when you factor in the speed and accuracy, along with the ability to expand the type of work you can take on, a CNC machine ends up being your most affordable option.

A Bridgeport and CNC Machine Rolled into One

CNC Masters—out of Irwindale, California—offers two CNC machines that incorporate the best features of a traditional Bridgeport-type vertical milling machine and a CNC machine.

CNC Supra Mill 9 x 49 and CNC Supra Vertical Milling Machine 10 x 54

Both Supra mills are easy to learn and operate, and they are capable of manual and CNC control. Each features heavy-duty cast-iron construction and three-axis interpolated movement with computer-variable spindle control.

The Supra 9 x 49 vertical milling machine is a classic CNC machine with a 9″ x 49″ table size and maximum travel of 34″ x 11.5″ on the X-axis and Y-axis. The Z-axis (spindle axis) has quill travel for accuracy.

Their larger model, the Supra 10 x 54, has a 10″ x 54″ table size along with 35.5″ longitudinal travel (X-axis) and 15.5″ on the Y-axis. Like the smaller model, the Z-axis is quill-driven.

The Supra CNC Milling Machines help you move your manufacturing business up to the next level while allowing you to keep your trade secrets to yourself. Our CNC milling machines have a smaller footprint, saving you the high cost of investing in additional floor space.

The Supra CNC machines are built in the USA and backed by an expert support team that will readily provide you with guidance—from setting up to troubleshooting any problems with the product.