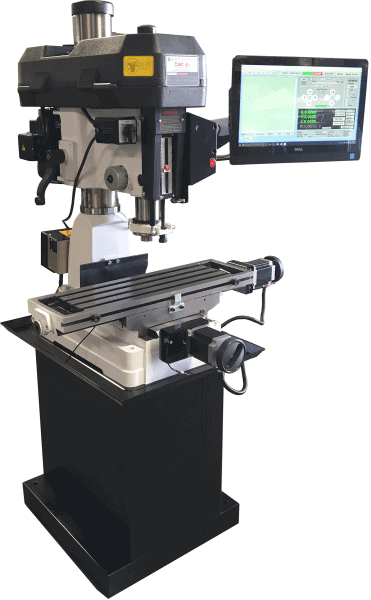

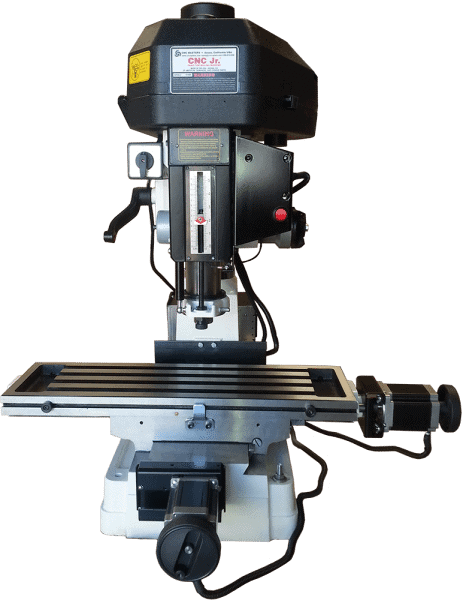

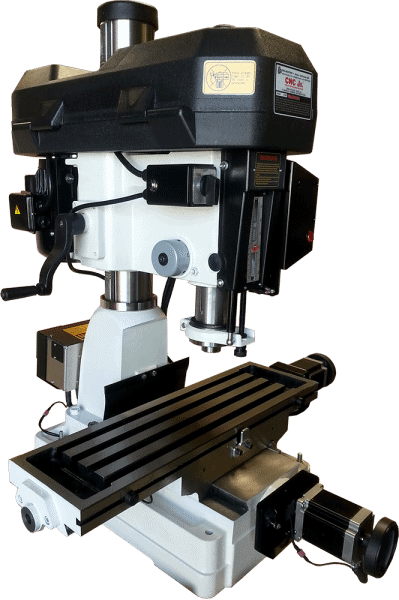

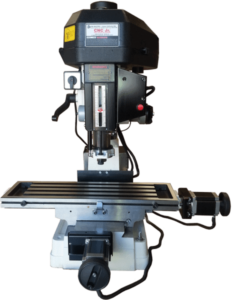

Recommended for general CNC machining, 3D surface milling and mold making. It includes a ready to run 3 axis CNC table top mill, user friendly MASTER Software with G-CODE file interpreter, X & Y ball screws with pre-loaded ball nuts, and CNC Control Unit. (requires 115 AC)

***Test out the Master MX to run your CNC Mill and be sure to check out the video here: Master MX Intro Video

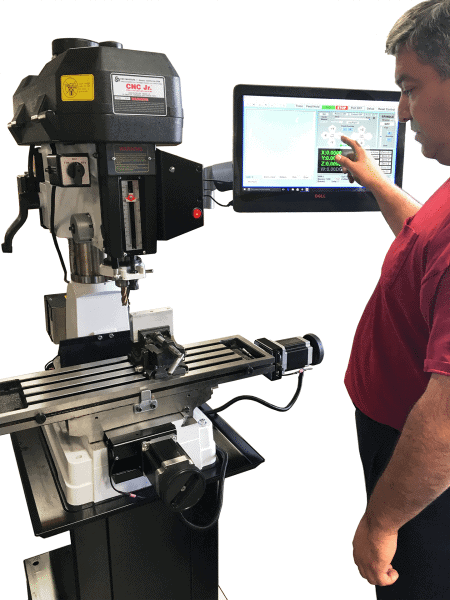

There might be something essential missing from your garage or workstation. Whether you are a hobbyist or a businessman with a small to medium-sized enterprise in need of machine parts, the CNC Jr. Table Top Mill is the perfect choice for you. This Jr. Table Top Mill is as powerful as the full sized model without the size. This smaller size milling machine comes to you already pre-built and hooks up easily to your computer. The software is easy to use and will help you get to your projects that much quicker. All CAD-CAM software is compatible with the table top mill machine as long as it produces standard FANUC based G codes. The CNC Jr. Table Top Mill comes with a one year warranty. In addition to a one year warranty, our company provides comprehensive quality testing on all of our machines. Any and all answers are just an email or phone call away. Call today to order your CNC Jr. Table Top Milling machine.

- Works with Windows 10

- Powerful X, Y, and Z axis micro-stepper motors – size 34 with 1200 in/oz torque

- Hand-wheels for manual option machining

- X & Y Zero Backlash Ball Screws with Pre-loaded ball nuts to eliminate table play

- X & Y Direct Drives – no timing belts to adjust

Reasons to Choose CNC Masters:

Support – We take our after-sales support very serious on our cnc machinery for as long you own the machine. Call or email as needed, we will be happy to assist along the way.

We are an American business based out of Irwindale, California. You will never be directed to an off-shore service.

All of our CNC Masters machines are built here in the USA. We test every machine for quality and reliability before we package and crate them here at our Irwindale facility.

Our machines are easy to use and learn, easy to maintain.

These are simple, low cost cnc machines that can be operated full time for productions runs, R & D work, small or large volume manufacturing.

An operator without cnc machining experience will pick up using these machines fast.

The CNC Jr. Table Top Mill Will Help Get Your Projects Done Faster

Compact

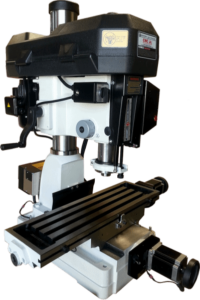

This table top mill has the power and performance of our CNC Bridgeport-type sized machine, without the large size. Whether you use it in your man cave or it ends up in your shop. Either way, you do not want to take up more room than what is necessary.

Versatile

We have received rave reviews about the CNC Jr. table top mill, from engineers, research institutions, high schools, universities, and small business owners who need to mass produce parts but are tired of paying someone else to do it. It is also popular with hobbyists, who are now able to have more fun than ever before since entire weekends are no longer spent trying to get that one part just right.

Easy-to-Use

The CNC Jr. table top milling machine arrives pre-built from our factory, and it easily hooks up to your computer. You will be able to master the software in no time at all, and you will be ready to machine parts in a matter of minutes.

Precise

Our software program allows you to get the cuts you want without a lot of time spent measuring and then re-cutting. Whether they are parts for that boat you are building for fun or important components for a research project, you need to get them done so you can get going with the other tasks you need to do.

Run your shop – or have fun with your hobby – for less. How much money have you wasted sending your parts to someone else to have them fabricated? How much time have you wasted on projects that you ended up giving up on and throwing away because you could not get the parts just right? With the CNC Jr. table top mill, you will not have to deal with these problems ever again.

The CNC Jr. Table Top Mill is Offered by CNC Masters with pride!

We are an American company based in Irwindale, California. We back our products with a hand-tested quality check, stellar e-mail or live telephone technical support, and a one-year warranty.

No shop – or project – is complete without the CNC Jr. table top mill, so order yours today.

The CNC Masters Testimonials:

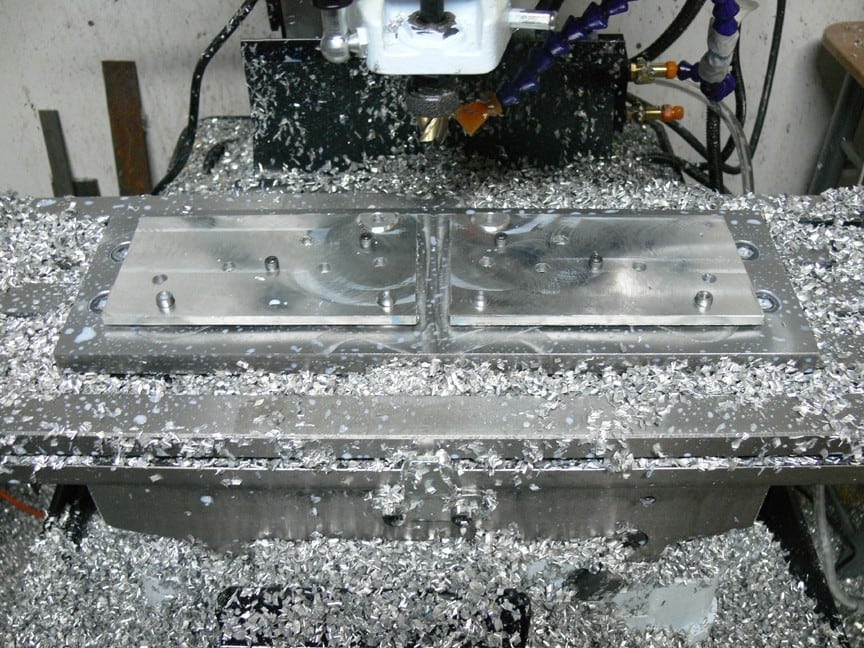

This picture was given to us by a satisfied customer, John Russell of Ruscool Electronics Ltd. from New Zealand using the CNC Jr. Mill. The CNC Jr. Mill is a popular machine that is purchased by many customers worldwide besides the USA. We take our aftersales support very seriously regardless if you are in the USA or abroad. These are just some of the countries that represent our customers who have purchased the CNC Jr. Mill or the CNC Jr. Retrofit Kit: South Africa, New Zealand, United Kingdom, Gabon, Thailand, Japan, Mexico, El Salvador, Philippines, Spain, Italy, Israel, Germany, Norway, Sweden, Vietnam, South Korea, Australia, Canada, Columbia, Argentina, Brazil, Puerto Rico, and Peru just to name a few!

“Many of the parts I have produced on much larger and more expensive machines could have been produced on the CNC Jr. The benefits of the CNC Jr. are less cost and less size. When we are looking at new machinery, we sometimes forget that the concrete these machines sit on is not free.” – John Kitchens, Dallas, Texas

These pics were given to us from Avro Enterprises in Ontario, Canada. He said it took him only 15 minutes to machine these two aluminum frames (third pic on right) using the CNC Jr. desktop milling machine.

“Being a hobbyist who enjoys designing RC model boats from the ground up, I have found the CNC Masters Milling Machine to be indispensible for the creation of custom design fittings, which in turn allow me to fit out my craft with one of a kind parts.” – Mark Moon, Queensland, Australia

The CNC Masters CNC Jr. Table Top Milling Machine

The CNC Jr. table top mill combines the high quality and power of our CNC Bridgeport-sized machines with space efficiency and ease of use. Machinists of any type always benefit from powerful machining products and shops are always cramped. By using the CNC Jr. Table Top mill, work areas are larger without sacrificing craftsmanship.

CNC Masters is proud to include the CNC Jr. table top mill in our product lineup, as we know it consistently helps our customers get work done the first time. Our customers range from individual hobbyists to larger businesses, even academic research institutions. This product allows any user to save time by creating their own prototype parts or producing the perfect components in-house.

Due to the simple and easy-to-use controls, the CNC Jr. table top mill can be set up and running within minutes of delivery. The CNC Jr. will arrive pre-built, eliminating any mechanical installation or time-wasting assembly procedures. Once the machine is in place, it will be ready as soon as a computer is connected. Furthermore, the bundled software is simple and easy to master. Difficult and complex designs are easily manipulated and controlled so cuts are done right the first time, regardless of the application.

Any CAD-CAM software is compatible with our table top mill as long as it produces standard FANUC based G-codes. Customers have employed AutoCAD, Alibre, MasterCam and others to produce G-codes that our Master Software uses to mill and cut parts. Different file formats, such as IGES, DXF, and DWG, can be imported and read by the Master Software.

As with any of our products, CNC Masters provides unlimited technical support for our customers. Every one of our products is manufactured and tested in the United States and the CNC Jr. table top milling machine is no exception. We welcome our customers to contact us with any questions. We are available for support through email for non-urgent situations or over the phone for any type of concern. Please contact us at any time to receive prompt and professional assistance.

With the CNC Jr. table top mill, projects are finished on time and for less. Regardless of the application, the CNC Jr. will provide the same power as a larger machine but with a far smaller footprint. Complete any workshop with the CNC Jr. mill today.

There might be something essential missing from your garage or workstation. Whether you are a hobbyist or a businessman with a small to medium-sized enterprise in need of machine parts, the CNC Jr. Table Top Mill is the perfect choice for you.

Manufactured by: CNC Masters

Reviews

There are no reviews yet.