CNC Lathe 1340 Turning Center

This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

Like the 1440 CNC Lathe, the 1340 CNC Lathe machine can revert back to manual operation instantly. The ease of use that the 1340 incorporates also guarantees that even the most complex operations can be done as swiftly and easily as more simple procedures. The same features allow the 1340 to be relied on for continuous high-quality operation over long productions, regardless of the application.

Producing parts in-house ensures a high level of quality, often keeping costs down for many manufacturers. Additionally, efficient production lines and manufacturing times prove to be crucial for success. To this end, most machinists seek CNC lathes that incorporate easy-to-learn features that can produce parts the day the machine is set up.

Our CNC technology is unique and new to the field; it combines a conventional manual lathe machine with the power of automation technology through CNC. This ease-of-use allows for advanced control by even novice operators. In doing so, creators can fabricate parts without outsourcing to competing companies, designers will no longer wait for parts, and small operations can program complex procedures to save time and money. The CNC Masters 1340 Lathe machine can create a small toolpath program to control the X and Z axes repeatedly with minimal interaction from the user.

Made for primary or secondary applications, the 1340 CNC Lathe is a gear head bench top mid-size turning center. Different from other cnc lathes, our 1340 takes up far less space than larger machines while continuing to deliver the same high-level performance. All types of machining shops will benefit from the 1340, but it truly shines when utilized in smaller areas and for smaller operations. A fantastic investment for any shop not wanting to outsource parts and orders, the 1340 will lower production costs by allowing a shop to produce in-house. The small size of the 1340 lathe machine ensures any shop will be able to house the machine while still being able manufacture most applications within 13″ on the swing or 8″ over the cross slide, and 35.25″ on the carriage travel.

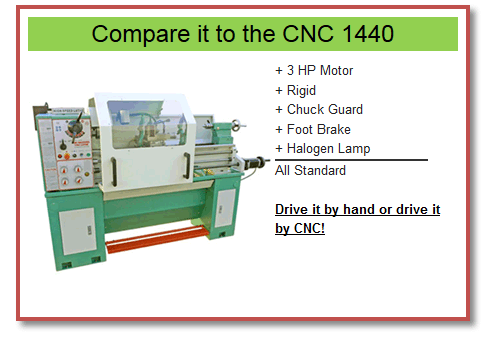

While slightly smaller than the CNC Lathe 1440 turning center, the 1340 still provides any user with the same level of high-quality performance. CNC Masters believes that the 1340 CNC Lathe machine offers some of the best results, and we commit to our product. Built to be extremely space-efficient while retaining the features of a larger machine, the 1340 also boasts a smaller price tag than larger, more complicated machines that require specialized technicians to service.

The 1340 CNC Turning Center represents a new take on a classic machine, and it represents a viable and desirable solution for machining shops throughout the industry, whether machinists need to fabricate a single prototype or automate a large run of a complicated part. Coupled with our time-saving accessories designed for CNC, the 1340 CNC Lathe truly becomes an elite lathe machine.

CNC Masters values all of our customers. As with our other products, we welcome any comments or questions concerning the CNC 1340 Lathe. Our company considers our customer service to be one of our greatest assets, and the relationships we build with our customers are among our top priorities. While we completely stand behind our products, please contact CNC Masters immediately should you have any questions or issues with your CNC Lathe machine.

CNC Masters keeps prices low while maintaining high-quality products, but we realize that CNC machines can represent a major purchase. To offset the initial investment for small firms interested in machines like the 1340, we offer financing options. Contact us for more information, or use our online form to apply.

EVERY CNC MASTERS 1340 CNC LATHE TURNING CENTER IS HAND-TESTED FOR QUALITY AND PERFORMANCE BEFORE LEAVING OUR MANUFACTURING FACILITY IN IRWINDALE, CA.

The CNC 1340 Turning Center: Built for the Independent Shop Owner

Designed with the independent shop owner in mind, the CNC 1340 Turning Center is the ultimate lathe machine to bring control and greater profit to your own business. This machine was built to allow for fast and reliable automatic product development; but at the same time, it can be quickly converted to manual operation to bring the best of both worlds to an independent shop.

Designed to be reliable, portable and compact, the 1340 CNC lathe opens new frontiers for the independent business. With a simple hands on learning process and integrated to work flawlessly with most CAD and CAM software programs, the CNC 1340 CNC lathe machine can spell the difference between breaking even versus a profitable year.

There are many advantages to operating your own turning center. In addition to always being first in line for your development needs, you can also keep your trade secrets and upcoming projects under wraps until you are ready to launch your new creation. The extremely competitive pricing of the 1340 CNC Lathe also makes it the machine of choice when you do decide to take control of your own business matters and product development.

Perhaps most important to consider when you choose to outfit your shop with the 1340 CNC Turning Center is the fact that you have the full support and expertise of CNC Masters, who will be by your side from the point of delivery and throughout the life of your valued equipment. In fact, you will find that even before you become a valued customer of CNC Masters, the benefits of working with such a quality company becomes evident through the very flexible and customer-oriented financing program. You can get up and running without a significant outlay or delays from looking outside for more financing options, which turn out to be more expensive.

Contact CNC Masters today to improve control over your operations and the bottom line of your balance sheet! To learn more about this machine, feel free to browse the links below and on the sidebar for specifications, a video, and the accessories we offer for it.

John runs his own business. He has a cad design he needs to have machined but is unsure what his best option is. He knows he could work with a third party machine shop but without a large bulk order this is expensive, time-consuming and frustrating to deal with. Orders can be late, parts made incorrectly and John is stuck dealing with someone outside of his organization. What if he could machine his own designs in house, cheaply and easily?

With CNC Masters he can. CNC Masters offers high quality, affordable machining products and software that give business owners flexibility and control over their machining process. With the CNC Masters machine, John can machine a single piece to prototype his latest invention, or turn out production runs 40 hours a week.

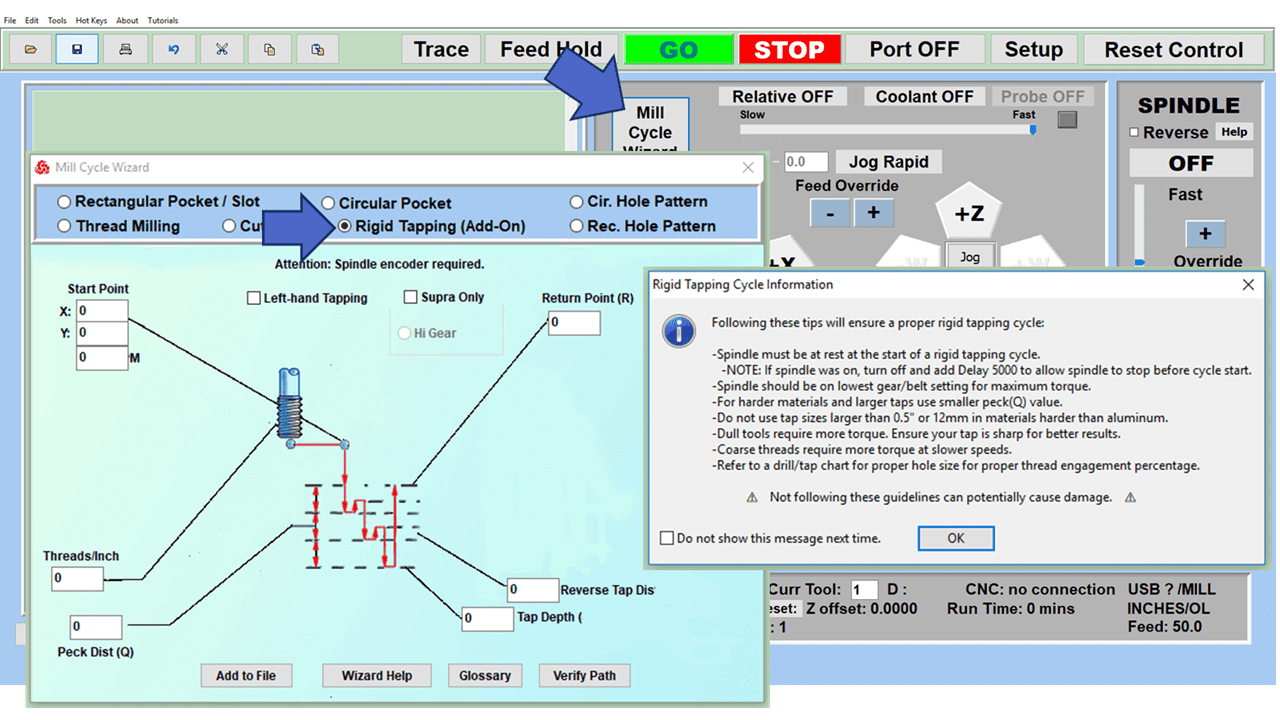

Our Master software is easy to learn and with cam software being so intuitive John can quickly take a cad drawing, convert it into a tool path program and import it into the Maters software to run his CNC Masters machine. Meaning John will be automatically machining his part in no time and you can too; With CNC Masters, keep profit margins high by owning your own machine. Just install the software on to your PC, load your cad drawing and let the cam software do the rest. Plus, you are never alone.

CNC Masters tech support is included as long as you have a CNC Masters machine. We will help you troubleshoot mechanics, electronics, and the Master software directly by phone or email. Now that’s support! The ROI is undeniable. Contact CNC Masters today and get started milling your own parts.

Reviews

There are no reviews yet.