CNC Lathes

CNC LATHES FOR SALE

CNC Masters is proud to present our catalogue of CNC lathes, including the 1340 and 1440. With the CNC Masters 1340 and 1440 CNC Lathe, you can cut down on the need to outsource work to produce prototypes or even complete projects.

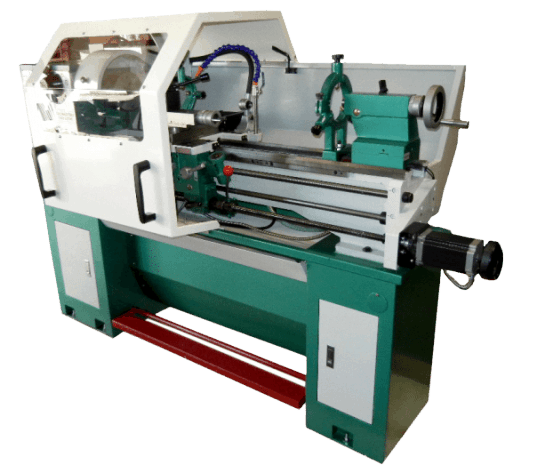

CNC 1340 Manual Lathe Turing Center -- Out of Stock

The CNC Masters 1340 CNC Lathe, allows you to cut down on the need to outsource work to produce prototypes or even complete projects.

- Powerful size 34 Z-axis micro-stepper motor within 1500 in/oz of torque

- Very accurate with micro-stepping motion

- X & Z Direct Drives – no timing belts to adjust

- X & Y Zero Backlash Ball Screws with Pre-loaded ball nuts to eliminate play

- Full 2 Axis coordinated motion control on bipolar motors – True interpolation

- Transition between CNC and Manual modes

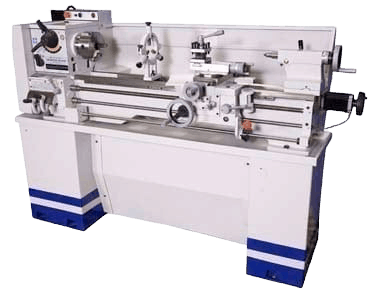

CNC 1440 Manual Lathe Turing Center

The 1440 CNC Lathe has the ability to revert to manual control quickly and efficiently, eliminating the need to write a CNC program for short runs. At the same time, its advanced CNC capabilities transform complex turning applications into simple designs that can be programmed and executed accurately many times over on production runs. The CNC MASTERS 1440 Lathe is a Gear Head Bench Top mid-size turning center made for primary or secondary CNC machining applications. This 1440 lathe is intended for the user needing the ability and performance of a true CNC working lathe without taking up floor space like larger, expensive CNC machines which require highly skilled trained CNC machinists and service technicians to tune and maintain the machine for you. Turn, face, chamfer, or machine threads on your part with this CNC Lathe. You can machine just about any application within 13″ on the swing or 8″ over the cross slide, and 35.25″ on the carriage travel.

- Versatile machine that instantly converts from CNC to Manual mode

- 40″ Distance between centers with 14″ swing over bed

- Full 2 Axis coordinated motion control on bipolar motors – True interpolation

- Home Reference sensors on the X & Z Axis

- 3 HP main spindle motor

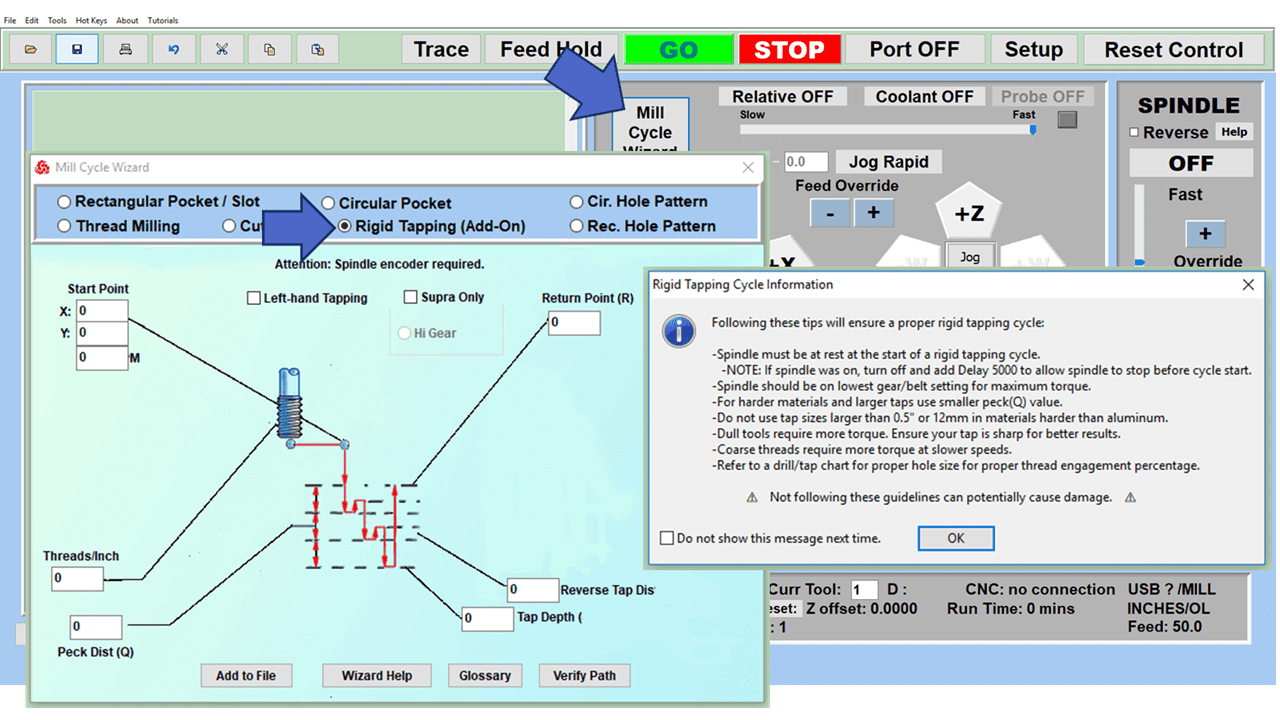

- CNC Masters custom software is included

Birmingham Lathes

Our line of Birmingham Lathes are designed and used by expert machinists around the world. Each lathe is made in the USA with the highest standards. Go ahead and browse our collection Birmingham lathes to see the variety we offer.

What is a CNC Lathe?

A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though. The process of cutting any workpiece that rotates on the spindle is known as ‘turning’. As the spindle is rotated, the material is removed and formed through drill bits and cutting tools, of different widths and shapes. Eventually, the lathe produces a symmetrical product. These machines have the capability to produce many different details on the rotating workpiece through different cuts and shapes. A CNC machinist can program their lathe to make hard cuts on very tough materials while also producing high-caliber pieces at high volumes.

READ MORE