Computer numerical control (CNC) technology has revolutionized the world of manufacturing and machine tools. With the help of CAD/CAM software, it can translate complex geometries and shapeless workpieces into parts and components with astonishing speed and high precision.

Although the machines come in several varieties, including CNC lathes, CNC routers, and 3D printing machines, the most commonly used CNC machining centers are the 3-axis and 5-axis CNC machines, each with unique advantages and applications.

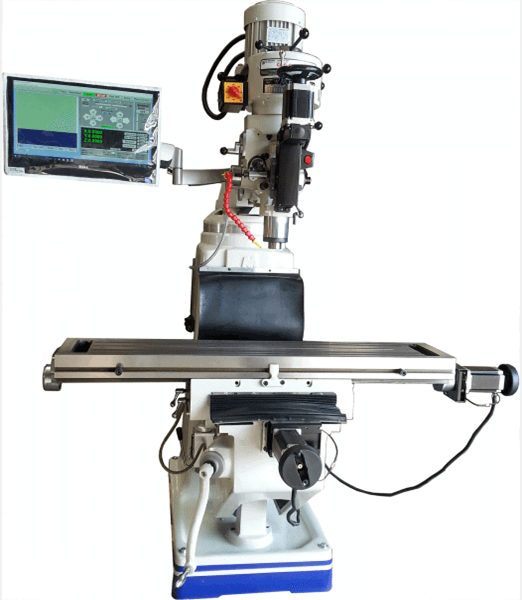

A 3-axis CNC machine operates along three primary axes of motion: the X-axis (left to right), the Y-axis (front to back), and the Z-axis (up and down). This machine is known for its versatility and can produce a wide array of parts relatively quickly. It is a staple in numerous manufacturing environments, where it lends itself well to high-volume, lower-complexity production runs.

On the other hand, the 5-axis CNC machine, in addition to the X, Y, and Z axes, can rotate along two additional axes. These rotational axes allow for more intricate and complex part designs, making it a favorite choice for industries requiring high-precision machining operations. This comparative guide highlights these cutting-edge machining technologies’ specific attributes, benefits, and suitable applications.

What is a 3-axis CNC machine?

A 3-axis CNC machine has become one of the most popular machine tools used in manufacturing processes. “3-axis” refers to the ability of the machine to move in the X-Y-Z linear axes. As mentioned, they work in three different directions: the X-axis (left to right), the Y-axis (front to back), and the Z-axis (up and down) to remove material.

The 3-axis CNC machine is versatile and remarkably efficient in producing complex geometries and contours, such as those found in molds, dies, and various machining parts. With the help of cutting tools and minimal human intervention, these machines can produce a high volume of parts with exceptional accuracy and consistency.

In addition to their precision and versatility, 3-axis CNC machines greatly enhance productivity. Because of automation, these machines operate around the clock and produce parts with minimal supervision, increasing the overall efficiency and throughput of the manufacturing process and reducing errors and rework, thereby saving time and resources.

What are the applications of a 3-axis CNC?

The 3-axis CNC is a pivotal part of modern manufacturing and prototyping. Its applications span various sectors because of its accuracy, efficiency, and versatility.

In the automotive industry, 3-axis CNC milling machines can manufacture parts like engine components or custom modifications with high precision. They ensure consistency and quality, which are vital in this industry, where a small error can lead to catastrophic consequences.

In the aerospace industry, these machines produce complex shapes and critical components. The complexity of aerospace parts often requires close tolerance machining that only a CNC machine can provide. Accurately replicating components is crucial in this sector to maintain aircraft safety and performance.

The 3-axis CNC finds applications in creating surgical instruments and medical devices in the medical industry. It also plays a role in creating orthotic devices and prosthetic limbs. The accuracy of CNC machines is critical in this field, where precision can affect a patient’s health and recovery.

In the construction industry, machinists use 3-axis CNC machine tools to precisely cut construction elements like wood, metal, or glass. They can generate high-quality customized pieces that fit perfectly into specialized designs or structures.

In the arts and crafts sector, these machines have empowered artists with the ability to create intricate designs with precision, ranging from sculptures to delicate jewelry pieces.

3-axis CNC machines have revolutionized these industries by providing precise, consistent, and repeatable results which increase productivity and reduce waste. Their versatility allows for manufacturing parts that would be impossible with manual machining techniques. As technology advances, so will the capabilities and applications of 3-axis CNC machines.

What is a 5-axis CNC machine?

The 5-axis CNC machine is another multi-axis weapon in the manufacturer’s arsenal, notable for its ability to operate on five different axes simultaneously. It can machine a workpiece from five different directions, distinguishing it from the 3-axis CNC machine. Those two additional axes–the A-axis and B-axis–combine with the X-Y-Z linear axes to form the 5-axis CNC machine.

The A and B axes are rotational, allowing the workpiece to be rotated around the X and Y axes, respectively. This extra rotation capability provides a broader range of motions and improves geometrical precision. Additionally, there are cases where the machine moves to the C-axis instead of the B-axis. The C-axis indicates the rotation along the linear Z-axis.

A key advantage of 5-axis CNC machines is reducing setup times. Unlike 3-axis machine tools, which often require the workpiece to be manually repositioned for different operations, a 5-axis machining center does this automatically, significantly reducing human error and increasing the manufacturing process’s overall efficiency. Moreover, the advanced capabilities of 5-axis CNC machines make them ideal for producing complex parts with one setup, reducing lead times and increasing productivity.

What are the applications of a 5-axis CNC?

A 5-axis CNC machine has numerous applications across various industries. One significant application is in the aerospace industry, where complex shapes and high precision require an extra number of axes to produce them. 5-axis CNC machines create complex shapes and angles in aero-engine components or airframes.

In the automotive industry, 5-axis CNC machines create prototypes, engine components, and custom parts with intricate designs. These machines provide the accuracy needed in manufacturing high-performance vehicles and detailed automotive parts.

The medical industry also benefits from the precision offered by 5-axis CNC machines. These machines create medical equipment and orthopedic implants like hip and knee replacements because they can produce these highly specialized components’ complex and organic shapes.

In addition, the energy sector counts on 5-axis CNC for creating components of turbines, especially wind turbines, where optimal efficiency comes from precision-crafted parts produced with accuracy and consistency.

These are only a few examples of how 5-axis CNC milling machines contribute across various industries. Their ability to machine complex shapes and close-tolerance parts makes them essential equipment in high-standard manufacturing or production.

Choosing between 3-axis and 5-axis CNC machines

When it comes to accurate high-speed machining, both 3-axis and 5-axis CNC machines have great capabilities but with notable distinctions between them.

5-axis CNC machines are the biggest, baddest, most complex machine tools available today. They also carry a corresponding price tag. Only the most advanced applications require the full range of a 5-axis CNC machine. In those situations, 5-axis CNC machining centers provide automation, high-speed, and high-precision manufacturing solutions.

Most smaller machine shops and toolrooms don’t need the full capability of a 5-axis machine; a 3-axis machine, along with some creative workpiece mounting and a bit more work, will do the trick just fine. Since 3-axis machines are less complex, they are also less expensive, making them a popular choice, especially for more straightforward applications.

Both 3-axis and 5-axis CNC machine tools have their place in today’s manufacturing environment. The choice between them should be driven by the project’s specific requirements, the complexity of parts, and the available budget.