Lathe technology has existed for centuries, dating back to the Egyptians around 1300 BCE. Later, around 1550 CE, lathe machines produced wooden products in France. By the time of the 18th century Industrial Revolution, workers in England were using a modern version of the metal lathe.

Unlike milling machines, where the cutting tool rotates, and the workpieces move into it, the lathe’s cutting tool is fixed and moves into a rotating workpiece, creating cylindrically-shaped parts. By definition, lathes have two axes: a Z-axis moving a cutting tool along the axis of the workpiece (toward the spindle) and an X-axis moving perpendicular to it (as in facing operations).

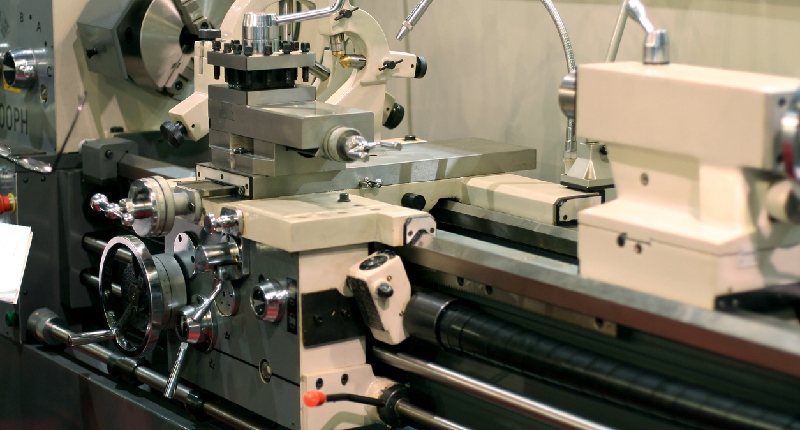

The original manual turning machines were integral to nearly every job shop, working side-by-side with milling machines and other machine tools in various manufacturing processes. And although two types of CNC lathes exist—horizontal and vertical turning centers—we will focus on the horizontal variety in this article to avoid confusion since more people are familiar with them.

Let’s start with the basics:

What is a Lathe Machine Used For?

Today, there are few limits on what a lathe can produce. Most lathes are used for industrial purposes, with horizontal turning centers involved in high-production machining and small machine shops using a standard engine lathe to work on projects such as replacement parts for an older machine or vehicle.

Automation has relegated the two-axis lathe to a predominately supporting role since the advent of computer numerical control, or CNC machining, over the last fifty years. However, these manual versions are so versatile that they will likely never be entirely replaced by modern technology. And hobbyists and small enterprises will continue to find that manual lathes meet their needs and their budgets.

What are the Technical Differences between Lathes and Turning Centers?

There is no hard and fast rule for making the distinction. Further muddying the waters is that CNC turning centers and lathes often look alike. Still, they usually refer to entirely different machines. Whether the lathe is a manual or CNC lathe, if it is capable of only two-axis (X and Z axes) machining, it is considered a lathe. The machine can perform operations including turning, facing, threading, knurling, drilling with the tailstock, boring, reaming, and taper turning. Still, each of these requires only the two axes and single spindles that are part of a lathe.

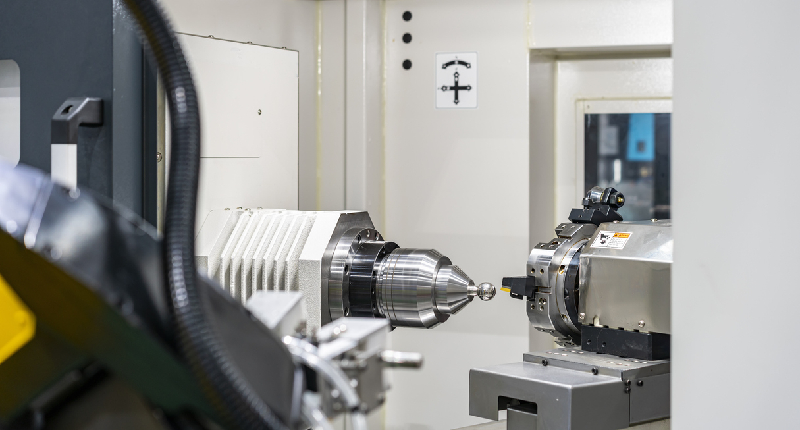

Lathes that include 3-axis, 4-axis, and 5-axis capabilities are known as turning centers, and they are an “evolutionary leap” from the CNC and manual lathes of the past. While traditional lathes rotate a workpiece as a cutting tool removes material to create a round part, multi-axis turning centers are far more versatile in their cutting ability. Adding the extra axes and twin spindles allows turning centers to perform operations beyond a traditional lathe’s capabilities.

Turning centers have cutting tool turrets for automated tool changing, live tooling, efficient chip removal, and a fully enclosed design for added safety and to keep high-speed coolant inside. Using sub-spindles for milling and drilling on multiple axes allows parts to be completed in one setup, eliminating the need to remove a workpiece for secondary operations on another machine.

Turning Centers Improve Conventional Lathe Operations

Even those operations that can be completed on a lathe are more efficient on a turning center. Turning centers drill, bore, and ream holes with ease as the workpiece spins, but with the live-tooling features, they can also perform this operation when the piece is stationary. The cutting tools drill and finish holes wherever the specifications require them.

Threading and taper cutting are time-consuming on a two-axis lathe, but they become quick and simple tasks with more than two axes. Turning center threading reduces machining time, and tapers can be applied anywhere along a workpiece’s length instead of only on its end.

What are the Advantages of Turning Centers?

A multi-axis turning center is particularly valuable for machining complex parts. Here are the four axes it employs:

- X-axis: As mentioned, this is the normal lathe cutting axis, referring to the movement perpendicular to the axis of the stock, as in a facing operation using the cross-slide.

- Z-axis: As the stationary cutting tool moves along the axis of the stock removing material, it travels along the Z-axis. Along with the X-axis, these are the two traditional lathe axes.

- C-axis: The C-axis is movement around the axis of the stock, so it is the same axis as the spindle. However, during milling operations, the main spindle drive is disengaged, and a servo drive controls the C-axis, enabling accurate positioning. A C-axis allows slots to be machined into the part and holes drilled in the X-axis plane.

- Y-axis: The Y-axis is moving perpendicular to the axis of the stock with a live tool or separate milling head. It works with the C-axis to mill slots and flats and drill holes off-center to the X and Z axes.

Some 4-axis CNC turning machines have turrets at both ends of the spindle, simultaneously allowing the machining of both ends of a workpiece. These models are helpful when machining long items such as axle shafts for the automotive sector.

Here are some benefits you can expect from 4-axis turning centers:

Versatile machining

Multi-axis turning machines allow turning operations and CNC milling capability on every workpiece surface. In other words, cutting slots, grooves, or designs on the front, back, top, and bottom with high precision is possible.

Complex design capability with speed

Combining a heavy-duty turning machine with CNC control and software enables intricate designs and configurations to be machined with shorter cycle times and higher accuracy. This benefit is essential for custom machining, rapid prototyping, and high-production work requiring a high-performance machine tool with multitasking capabilities.

Greater efficiency

Because multi-axis CNC machines act as turning centers and milling machines, companies can reduce the required machinery. For instance, there is no longer a need to cut round parts on a lathe and move them to a mill to add flats. The turning center completes all the operations on the same machine tool, increasing productivity, saving money, and minimizing waste.

Swiss Lathes: A Slight Variation on the Turning Center

The Swiss lathe is another type of CNC turning center capable of high production. They are based on the horizontal CNC turning center design described previously but add a few unique features. First, the headstock slides the material through a rotating collet as multiple tools engage the workpiece simultaneously, resulting in a “bar feeder” action for high production. Swiss Style CNC turning centers can mill, drill, turn, and tap, allowing them to produce parts accurately and quickly.

What is a Turning Center Used For?

Turning centers can produce parts for industrial use, including oil and gas, aerospace, automotive, construction, medical instruments, and military. Here are a few examples from different industries:

Aerospace

Turning centers play a significant role in producing parts for the aviation industry. Shafts, probes, eccentric hollow shafts, joint connectors, fasteners, landing gear parts, and structural components are just a handful of the items turning centers manufacture for the aerospace industry.

Automotive

The automotive industry needs parts and components in various shapes and sizes, and turning centers offer fast solutions to meet their demands. The machining includes gears, camshafts, transmission parts, steering components, hydraulic valves, valve housings, sensor housings, and clutches.

Electronics

Precision electronic parts must be produced with high consistency and reliability. Turning centers make earphone housings, computer panels, aluminum tubes for e-cigarettes, conductive pins, bushings, probes, and other electronic accessories.

Medical

Medical and dental instruments need CNC turning and machining processes to create packaging, processing machinery replacement and spare parts, R&D fixtures, analysis instrument parts, medical tooling, and medical mold components.

Mechanical

Parts used in the mechanical industry must meet specific technical specifications to ensure the quality of machinery or equipment. Some components include motor shafts, connector joints, shaft sleeves, hydraulic fittings, hose joint pipe couplers, and various fasteners.

How Much Do CNC Turning Centers Cost?

A standard CNC lathe typically starts at around $50,000. Add a Y-axis, and the price goes to almost $90,000, while a dual-spindle will set you back nearly $160,000. These are starting prices, and already they are beyond the budget of almost every independent shop owner or hobbyist. So, what’s the alternative?

CNC Masters offers the CNC 1440 lathe machine, an elite CNC lathe machine that seamlessly converts back to all original manual modes for added flexibility. Designed with the independent shop owner in mind, the CNC 1440 delivers high-level performance with a smaller footprint and provides excellent value at under $15,000 fully loaded!

Designed to be reliable, portable, and compact, the 1440 CNC lathe and turning center open new opportunities for independent businesses. With a simple hands-on learning process, the machine tool is integrated to work efficiently with most CAD and CAM software programs. And these turning centers are built for fast and reliable automatic product development.

Break free of third-party CNC machining and turning centers, and keep the entire manufacturing process in-house. The CNC 1440 is one item in our broad-ranging product line made and serviced in the USA with an ironclad warranty to back them up.

Talk to the CNC experts at CNC Masters, and discover the benefits of this excellent and affordable turning center today!