There are many different types of wood you can use for your home projects. Some people decide to use cedar because it is a very strong and durable type of wood. Others may choose to use oak because it has a beautiful grain and color that will add beauty to your project. But one type of wood that doesn’t get talked about as much, but should be considered when building any outdoor structure, is Ipe Wood.

Ipe wood or Brazilian Walnut is an amazing wood that has various benefits. It’s very durable, available in many different types of grades, and can last for decades with proper care. We are going to cover the most important points about this type of wood so you will understand what makes it so special and why you should choose it for your decking project or any other outdoor project.

Where is Ipe Wood From?

Ipe wood is found in South America especially in the Amazonian rainforest that has very hot temperatures, high humidity, and plenty of rainfall. Strong winds are also common in this area, which makes for the perfect environment to grow these types of trees.

The bark on ipe trees can be thick and they can easily adapt to any climate because they often absorb moisture from various rainstorms that occur throughout the year.

It is sometimes called Brazilian Walnut because it shares a lot of similarities with American walnut trees.

Ipe Wood Appearance

Ipe wood is a beautiful type of Brazilian hardwood that ranges from light brown to a very dark color. It has an intense grain pattern, but the deeper grains are not always visible when it’s finished and sanded. In general, this wood is very strong and dense with a medium coarse texture.

Ipe Wood Strength

The appearance of ipe wood can greatly vary depending on the grade or level you are looking at for your project.

Ipe wood has a Janka rating of about 3510 lbs. It is considered one of the hardwoods in the world.

There are also different levels of hardness that range from semi-hard to hard, which makes it important for you to do your research before you start a project. The more knowledge you have about the exact type of ipe wood you want, the easier it will be for you to find what you are looking for in your search.

Common Ipe Wood Uses

Ipe wood is often used for outdoor projects because it’s so durable and weather resistant. Decking, fencing, gazebos, and pergolas are all popular uses for this type of wood. It doesn’t require a lot of maintenance but does need to be sealed every few years in order to keep its color and protect it for the future.

You might also use Ipe wood to make interior home decors such as furniture, cabinetry, floors, and even decorative molding. Installing ipe wood throughout your home can be a great way to add value to your property by increasing the beauty of every room.

There are many different grades of Ipe wood, so it’s important to know what you are looking for before you make a purchase. The harder grades of wood will be more expensive, but they will also last much longer with proper care.

However, the most common use for ipe wood is decking, furniture, fencing, and siding.

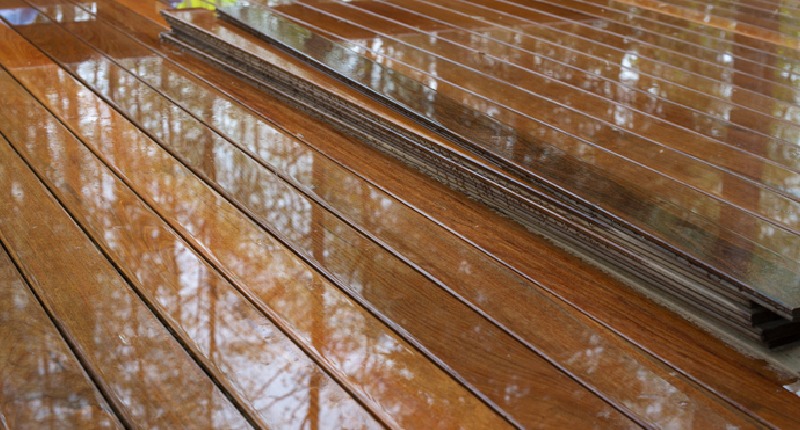

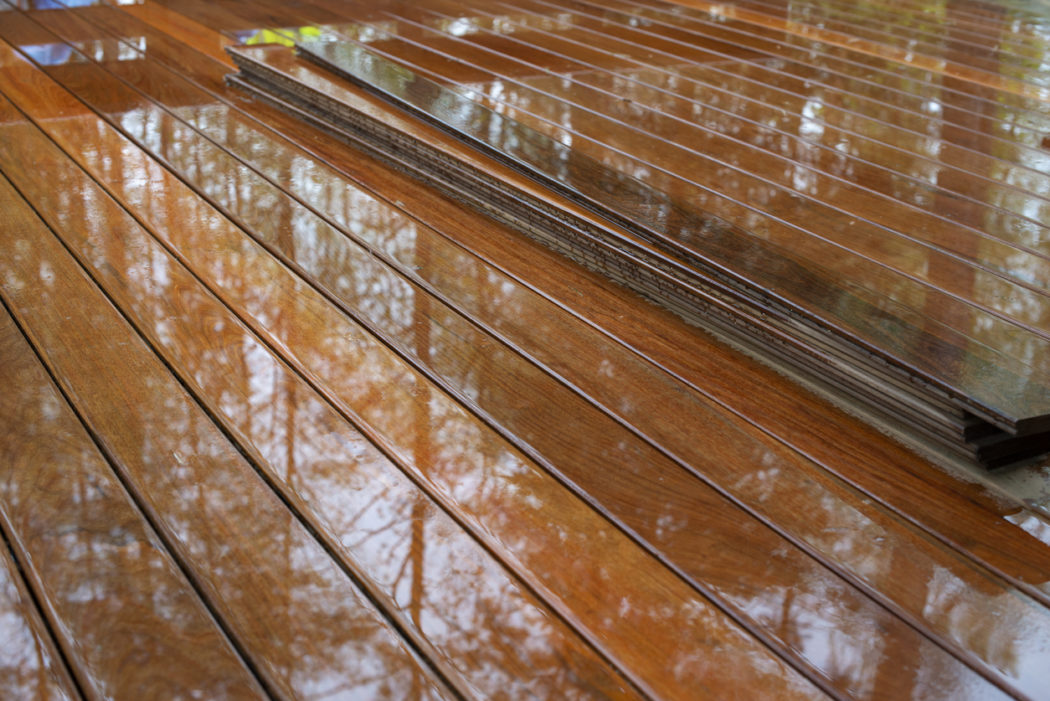

Ipe Wood Decking

Ipe wood is very popular around the world for decking because it’s a strong and attractive type of hardwood lumber. It is one of the densest hardwood decking materials. Due to its high density, Ipe decking is very durable and stands for a long time without warping, rotting, or needing replacement.

One of the biggest benefits of ipe wood for decking is that it’s available in many different grades and levels of hardness, so you will be able to make a smart choice when you are looking to complete your ipe deck projects. As long as you choose the appropriate level of toughness for your area, the ipe lumber can make an outdoor patio that won’t require much maintenance in the future.

The natural color of ipe wood is a beautiful dark brown, but it can also be stained or sealed to match any type of exterior décor. You will need to apply a sealant every few years to your ipe decking in order to protect it from weathering, but this will help keep its color and beauty for many years to come.

Ipe Wood Furniture

Ipe wood is often used to make quality furniture because it’s strong and has a beautiful grain pattern. There are many different types of ipe wood furniture available, but the more expensive pieces will typically be made with harder grades of lumber that can last for decades without warping or wearing down.

This type of hardwood is perfect for indoor and outdoor use, so you can get great pieces of furniture that will last for years to come. Furniture made with Ipe wood is often very heavy and requires two people to move it, but the benefits are well worth the extra effort.

You can find many different types of tables, chairs, couches, beds, and cabinets made with this type of lumber, so be sure to take your time and look for the perfect piece of furniture for your home. Ipe wood furniture is also a great investment that will add value to your property when it’s time to sell.

Ipe Wood Fencing

Ipe wood fencing is a great way to add privacy and security to your property while also increasing its value. This type of lumber is very strong and durable, so it can withstand the weather and keep its appearance for many years. It’s also a lovely material that looks great with any style of outside décor.

When you are choosing a type of fencing for your home, be sure to consider ipe wood. This lumber can be ordered in different grades and thicknesses to make sure that it’s the perfect fit for your needs. You will also need to decide on the height of your fence, but most types of ipe wood fencing come in 5 foot, 6 foot, and 8-foot height options.

Ipe Wood Siding

Ipe wood can also be used as siding for exterior walls to add a touch of elegance and style. This type of lumber is stronger than many other types of siding, so it will stand up well against the weather and other elements that might cause deterioration over time.

It’s also very easy to maintain. You can clean it with soap and water or a commercial cleaner, and you will only need to repaint it every few years depending on where you live. When you are looking for a way to add charm and personality to your exterior walls, this lumber is the perfect option.

How to Clean Ipe Wood

The best way to clean ipe wood is by using a mild detergent and a soft brush. Be sure to rinse the wood thoroughly after cleaning to remove any residue. You can also use a pressure washer if you have one, but be careful not to damage the wood with high-pressure water.

Cleaning your ipe wood deck is a quick and easy process that will help it look its best for years to come. You can use soap and water or a commercial cleaner to get the job done, but be sure to follow these simple steps:

1. Start by sweeping or hosing off any dirt or debris that is on the surface of the wood.

2. Mix a small amount of soap into a bucket of water and use a soft brush to scrub the decking boards.

3. Rinse the deck with clean water and let it air dry.

4. Apply a sealant every few years to protect the wood from weathering.

Follow these simple steps and your deck will look like new for many years to come.

If you have any grease or oil stains on your decking material, you can use a commercial cleaner to remove them. Be sure to follow the instructions carefully and test the cleaner in an inconspicuous area before applying it to the entire surface.

You will also need to reseal your finished deck every few years to protect it from the weathering effects of wind, rain, and sun. Sealing your deck will help keep it looking beautiful for many years to come.

Ipe Wood Pros and Cons

There are a few things to consider before purchasing ipe wood. It is important to be aware of the pros and cons of this type of wood so you can make an informed decision. Here is a look at some of the key benefits and drawbacks of ipe wood:

Pros

- Ipe wood is incredibly durable. It is one of the hardest types of tropical hardwood, which makes it naturally resistant to wear.

- It has low shrinkage and expansion rates. This means that your flooring won’t crack or buckle over time due to fluctuations in humidity levels.

- It has a dense composition, making it heavy and stable for an excellent foundation.

- It has a beautiful color. Ipe wood has a rich dark brown or honey color that looks gorgeous in any home or office space.

Cons

- Ipe is hard on tools, which makes it difficult to work with. It dulls saw blades quickly and requires some extra effort for sanding projects. It is also challenging to drill holes in this type of wood.

- The cost of ipe wood can be prohibitive for some budgets. It is one of the more expensive types of lumber available, but its durability and beauty make it a wise investment.

Overall, ipe wood is an excellent choice for flooring, decking, and other construction projects in all Brazilian hardwoods. Its long-lasting durability and beautiful color make it a popular choice for many homeowners and businesses. Be sure to weigh the pros and cons before making a purchase, but in most cases, ipe wood is a wise investment.

Is Ipe Wood Eco-Friendly?

One of the beautiful properties of Ipe wood is that it is eco-friendly. It is a renewable resource (tree) and its density prevents it from catching on fire easily. The resins inhibit insects and fungus growth while reducing sap seepage into the heartwood. When properly sustainably harvested, ipe can be safely reused for furniture, flooring, decking, and other applications for years to come.

As well, it is very sustainable, requiring little maintenance and reducing waste. Ipe wood leaves no harmful chemicals or poisons behind when used in construction projects, which makes it a good option for Eco-friendly businesses and households.

Is Ipe Wood FSC certified?

YES!

The Forest Stewardship Council (FSC) provides third-party certification for the benefits of environmental conservation, social welfare, and economic well-being. Ipe is one of many exotic lumber species that are certified by the FSC. This ensures that it comes from forestry operations that comply with sustainable harvesting practices.

Conclusion

The next time you are planning a construction or remodeling project, give some serious consideration to this Brazilian ipe wood. It is a durable and Eco-friendly option that will look stunning in almost any room at home or work. It is a great choice for those who want the very best in durable wood flooring, decking, and other construction projects. Its rich color looks gorgeous as a floor or as a wall covering and its incredible durability will stand up to your family’s needs for years to come.