Machine tools, like most equipment in the modern age, have both improved and gotten a bit smaller over the years. Modern lathes and mills have come a long way from the giant, room-sized machines of the Industrial Revolution. While you can still find room-sized machines in large factories and high-end production facilities, you’re also more likely than ever to find small machine tools in home workshops.

But even with advances in technology and affordability, most small lathes and mills are not CNC-equipped. For most hobbyists, that isn’t a problem, but it does mean that there are some things a small lathe simply cannot do.

Buying a CNC mill is beyond the scope of most hobbyists – most machines are too expensive or too large. Fortunately, there is a convenient workaround available for small shops or hobbyists who have a bit more time on their hands: a CNC milling machine conversion kit.

What are these kits, how do they work, and are they the right fit for you? Read on to find out.

What is a CNC conversion kit?

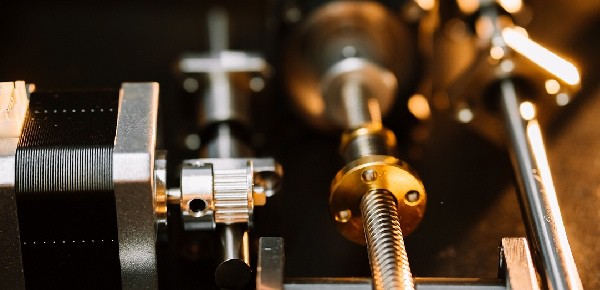

A typical CNC conversion kit for an older mill includes a range of new components, along with instructions for installation. There will be new hardware, including motors to give the mill automated movement along the X, Y, and Z-axes. You’ll also find a new control unit and software.

Other key parts might include:

- Home/limit switches – prevent the machine from damaging itself by moving to the extreme end of one particular axis.

- Motor control unit

Conversion kits vary widely; most are designed to work with certain older machines, or sometimes with certain families of machines – specific lines of machines by a specific manufacturer.

Some conversion kits will be quite extensive, including full electronics packages with control unit and programming software. Others are far simpler – the motors and other hardware needed to make the machine CNC-capable, but without the full control packages.

When shopping for a CNC conversion kit, you need to remember that it isn’t a “one-size-fits-all” solution. Find the conversion kit that is right for your machine.

How do conversion kits work?

Conversion kits take advantage of a mill’s current layout; they typically don’t add new axes of movement, but they motorize existing ones and allow pre-programmed movement. This keeps the work necessary to modify the mill to a minimum, making most conversions a matter of hours, not days.

When you receive your conversion kit, you’ll receive new hardware along with detailed instructions. Installing the kit may require removing components from your machine before installing new ones. Most conversion kits are marketed at DIY-ers and hobbyists, so the instructions tend to be accessible and understandable.

Conversion kit pros and cons

Why doesn’t every shop use a CNC conversion kit? Along with the benefits, there are some potential downsides.

Cons:

- Can’t replace broken components – a conversion kit is not a repair kit. While converting an older machine is a great idea, damaged parts will need to be repaired or replaced before your newly-converted CNC machine can work properly

- Limited capabilities – likewise, conversion kits don’t add a new range of motion or extra power to the mill’s original motor. The abilities of a converted CNC machine are limited by the original mill or lathe.

- Technical knowledge required – sellers market conversion kits to DIY-ers and small shops, but even then there is a chance that carrying out a CNC conversion will require a bit more technical skill than you have.

Pros:

- Cost-effective upgrades – the single biggest advantage of a CNC conversion kit is that it provides a cost-effective means of upgrading obsolete machinery. Conversion kits vary in price, but are typically less than half the cost of a new CNC machine – and sometimes far less than that.

- Allow high-quality customization – often, a hobbyist will use a conversion kit along with his own tweaks. This could be a custom control module modified from an old computer, or upgrades to the machine itself apart from the ones in the conversion kit.

- Increasing production abilities – a CNC conversion kit gives you all the capabilities of a fully-functioning CNC machine. Custom part runs, automated production, and a high degree of precision are all capable with a CNC conversion kit.

Is a CNC conversion the right choice for you?

Should you opt for a conversion kit, or simply go straight for a new CNC machine? A lot depends on your particular circumstances. If you need to open a new production line for a major manufacturer, it might be more cost-effective long-term to invest in a high-end, brand-new CNC machine.

However, if you are a smaller shop with tried-and-tested machines that are now obsolete, CNC conversion kits provide a fantastic opportunity to increase your capabilities without adding the overhead of a new machine. After conversion, you’ll have the capabilities of a genuine CNC machine – not a poor imitation – and the reliability of your old workhorse.

Of course, CNC conversion kits are also ideal for the home hobbyist, allowing them to upgrade their current machine at minimal cost and experiment with CNC programming, g-code, CAD, and all the other aspects of CNC machining.

While the prospect of upgrading your current milling machine might be daunting, the rewards – a high-end CNC milling machine at a fraction of the cost – are well worth the challenge.