One of the challenges of modern manufacturing is understanding how different machines and processes function. Understanding the difference between CNC turning and CNC milling allows a machinist to use the right machine to achieve the best results. In the design stage, it allows CAD and CAM operators to create parts that can be machined primarily on one device, making the entire manufacturing process more efficient.

Turning and milling processes overlap quite a bit but use a fundamentally different method to remove material. Both are subtractive machining processes. Both can be used for large or small parts across a wide range of materials. But the differences between them make each more suitable for certain applications.

In this article, we’ll cover the basics of CNC turning, CNC milling, how each is used, and the key differences between the two.

CNC Milling – Common Questions & Answers

What is CNC Milling?

Working from custom, usually computer-assisted design programs, CNC milling uses a variety of rotating cutting tools to remove material from a workpiece. The result is a custom part, produced from a G-code CNC program, that can be repeated as many times as desired to achieve a production run of identical parts.

What are the production capabilities of CNC Milling?

CNC milling is used in production runs both large and small. You’ll find CNC milling machines in heavy-duty industrial facilities as well as small machine shops or even high-end scientific laboratories. Milling processes are suitable for every kind of material, though certain milling machines may be specialized (i.e., metal vs. woodworking mills).

What makes CNC milling unique?

Milling machines generally fix the workpiece in place on a bed. Depending on the configuration of the machine, the bed may move along the X-axis, Y-axis, or Z-axis, but the workpiece itself doesn’t move or rotate. Milling machines typically use rotating cutting tools mounted along a horizontal or vertical axis.

Milling machines can bore or drill out holes or be making repeated passes over the workpiece, which can achieve a grinding action.

CNC Turning – Common Questions & Answers

What Is CNC turning?

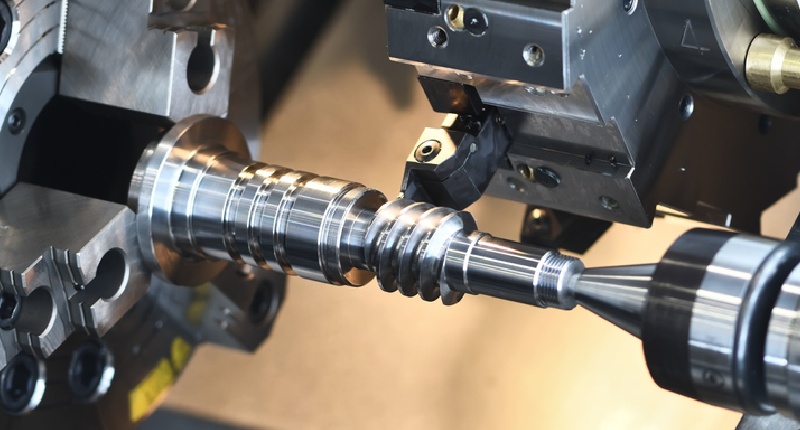

The process of turning is done by holding bars in a chuck and rotating them while feeding a tool to the piece to remove material until the desired shape is achieved. CNC turning uses computer numerical control to pre-program the exact set of operations for the turning machine.

How does CNC turning integrate with modern manufacturing?

CNC turning excels at cutting asymmetrical or cylindrical parts. It can also be used to remove material in the same shape – think of boring, drilling, or threading processes. Everything from large shafts to specialized screws can be crafted using CNC turning machines.

What makes CNC turning special?

CNC turning machines, like the CNC lathe machine, rotates the part itself while generally using a stationary cutting tool. The resulting cutting operation allows CNC turning machines to tackle designs that wouldn’t be possible with traditional CNC milling machines. The tooling setup is also different; the stability that comes from mounting a workpiece on a rotating spindle between headstock and tailstock allows turning centers to use cutting tools that a fixed. Tools with angled heads and bits can produce different cuts and finishes.

Live tooling – powered cutting tools – can be used on CNC turning centers, though it is more commonly found on CNC milling machines.

The differences and similarities between CNC milling and CNC turning

CNC milling uses rotary cutters and perpendicular motion to remove material from the face of the workpiece, while CNC drilling and turning allows engineers to create holes and shapes into the blank with precise diameters and lengths.

The basic idea behind CNC turning is simple enough — it’s just like using any lathe except instead of holding the piece steady, you hold the spindle itself. The difference lies in how the machine moves along its axis. In most cases, the spindle will be attached to an electric motor that spins at high speeds, allowing the operator to turn the entire assembly through 360 degrees without having to stop every time. This means that the whole operation takes place on one continuous cycle.

Both processes use CNC control to pre-determine the exact order of operations. Make a cut of exactly a certain length, then move to a precise spot on the workpiece, make another cut, etc. – CNC allows the entire process to be pre-set exactly.

For that reason, both CNC turning and milling are highly automated. Actual cutting operations are completely hands-free; operators need only troubleshoot and, if necessary, load the next round of parts.

When to consider CNC milling instead of CNC turning

When designing a part, CNC milling is best-suited for surface working (grinding and cutting), as well as for symmetrical and angular geometries. CNC milling machines are available as horizontal milling machines or vertical milling machines, and each subtype has its own unique properties. A well-built vertical mill is surprisingly versatile, making it ideal for precision work of all kinds. Horizontal mills, or heavier, production-level vertical mills, are often designed and built for high-end, high-volume production runs. You’ll find industrial milling machines in virtually every modern manufacturing center.

CNC turning, on the other hand, is generally well suited for prototyping low-volume production. For asymmetrical and cylindrical geometries, CNC turning excels. CNC turning centers can also be used for high-volume production of certain specialized parts, such as screws or bolts.

So what’s the big difference? Both CNC machines are crucial parts of modern CNC machining. Turning machines rotate a part, while milling machines rotate the cutting tool. A skilled machinist can use either machine or both, to create parts cut to exacting tolerances.