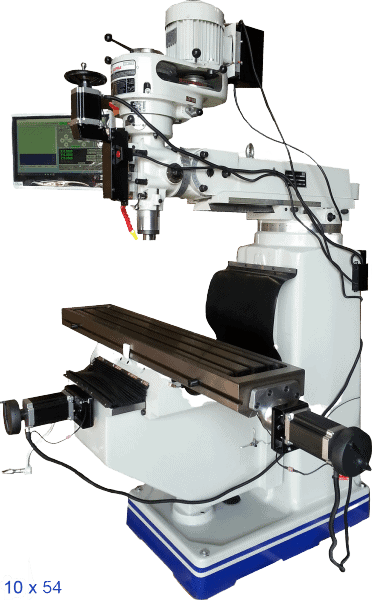

Vertical Milling Machines

vertical mills and vertical knee milling machines

At CNC Masters, we are proud to offer a unique line of CNC vertical milling machines. Each of our vertical mills is handcrafted right in the USA and supported by a team of specialists. Browse below to see our offerings and give us a call today with any questions or to start an order.

Classic Bridgeport Style Vertical Knee Mill CNC

Offered exclusively through CNC Masters, the CNC Supra Vertical Knee Mill is a strong and durable product, and offers the same benefits as a manual-driven Bridgeport vertical knee mill.

With simple-to-learn turnkey operation, this mill is suitable for any beginner machinist, as well as those with more experience who are interested in cutting parts the same day. The innovation and ingenuity of the CNC Supra Knee Mill allows for machining of complex and intricately designed parts through the use of automated technology. It also offers the option of manually machining simple parts by utilizing the hand wheels of the axis.

Table Top Milling Machines

CNC Masters offers three of the best Table Top Milling Machines. Each of our milling machines is turn-key, and easy to both learn and operate. All CNC Mills are built in the USA and come with our specialty MX Software and US-based support.

Frequently Asked Questions

A vertical milling machine is the most popular type of milling machine. It generally comprises a vertically oriented spindle that often holds, and rotates, the cutting machine against a stationary workpiece. Typically, the spindle can move up and down, and at the same time pushing against the workpiece to discharge material.

In general, there are two distinct kinds of vertical milling machines: bed milling machines and turret milling machines. When it comes to a turret milling machine, the table and spindle can move parallel and perpendicular to the axis. On the other hand, bed milling machines usually move the table only perpendicular to the axis. Due to the versatility feature that comes with turret milling machines, most manufacturing companies find it as a more preferable option. In most cases, they can carry out a wider range of milling projects as compared to bed milling machines, which makes them an ideal investment for many manufacturing companies.

A vertical milling machine is typically a precision tool that’s useful in fabrication and shaping by the removal of stock often from metallic workpieces. Based on the material and tooling, the mill can also machine plastics, as well as other materials. There are three main methods of operating mill controls: manually, computer numerical controlled (CNC), or perhaps a combination of both. Typically, mill machining and removal of material are done by a rotary cutter located in a spindle.

In comparison to a drill press, the cutting options are variable and more sophisticated by a vertical spindle movement (z-axis) and a moveable table and vice (x and y-axes). Additionally, most vertical mills consist of a rotatable turret primarily for the device’s upper cutting head that offers even better machining options.

Some of the common operations that a mill can deal with include:

– Slotting or keyways. Keyways, flats, or slots can be cut with correct fixturing

– Milling. In general, these operations offer a flat spot or surface on a workpiece, usually with a particular orientation to another piece, or other workpiece surfaces and features. Sometimes facing is applied on an irregularly shaped workpiece in order to “true” a single surface at a time and make sure that every surface has a suitable specific geometric correlation with each other.

– Drilling or boring. Where certain orientations are needed between workpiece features, this vertical mill offers the means to index and machine holes precisely.

Both milling machines have their pros and cons and making a choice between the two relies wholly on the type of milling that requires to be carried out. The number of planes needed to work on a piece, as well as the size and the shape of the piece, are huge factors in determining if the milling is more suited to horizontal or vertical milling.

The biggest difference between these milling machines comes in the orientation of the spindle. The spindle entails a vertical orientation in vertical milling machines. With horizontal milling machines, on the other hand, the spindle entails a horizontal orientation. Simply put, the horizontal type mounts the cutting equipment on a horizontally oriented spindle, which can selectively remove material from the specified stationary workpiece.

Additionally, horizontal milling machines typically consist of different cutting tools compared to vertical milling machines. For vertical milling machines, they often comprise long and slim cutting tools, whereas the tools are shorter and thicker with the horizontal milling machines. Also, the latter can carry out heavier, deeper cuts compared to the former. For this reason, most manufacturing companies use them to cut slots or grooves into workpieces.

Learn more about the difference between horizontal and vertical milling machines.

Manual milling machines are widely popular for cutting and shaping solid metal pieces into precision parts. These machines come with rotary cutters that can cut and remove metals by making small cuts. You can differentiate manual milling machines from other counterparts by the orientation of their cutting spindles. Also, you will find two types of manual milling machines: one that works horizontally and another that works vertically.

Vertical milling machines are ideal for precision cutting. All the spindles in this machine have a vertical orientation. This allows them to cut both the bottom and the top sides of your workpiece efficiently. Therefore, if you need very specific or very minute cutting, you should always use a vertical milling machine.

Horizontal milling machines, on the other hand, come with horizontally-mounted spindles placed on the arbor. The table on which the arbor rests has an XY plane that consists of the horizontal spindles. These machines are best for machining heavy or large pieces of metal. The work envelope in these machines is bigger than their vertical counterparts. Moreover, the configuration and mechanism of horizontal milling machines allow you to rapidly remove large pieces of unwanted metals.

Most people use manual milling machines so that they don’t have to make frequent tool changes. Some of the advanced manual milling machines come with indicators. These indicators contain a vertical dial that allows you to see the machine’s position while zeroing any metal part. Manual milling machines have the flexibility to work with multiple combination squares against your master square comparator. This will offer a micrometer depth stop graduated to 0.002″.

Another advantage of manual milling machines is the wedges fit in any T-slot tightly. Many users adjust the height and width for special clamping purposes.