This CNC Lathe will instantly revert back to its manual capabilities eliminating the need to write a CNC program for short runs. Its advanced CNC capabilities can turn any complex turning application into a simple one that can be programmed and executed accurately many times over on production runs. The CNC MASTERS 1340 Lathe is a Gear Head Bench Top mid-size turning center made for primary or secondary CNC machining applications. This 1340 lathe is intended for the user needing the ability and performance of a true CNC working lathe without taking up floor space like larger, expensive CNC machines which require highly skilled trained CNC machinists and service technicians to tune and maintain the machine for you. Turn, face, chamfer, or machine threads on your part with this CNC Lathe. You can machine just about any application within 13” on the swing or 8″ over the cross slide, and 35.25” on the carriage travel. THE CNC MASTERS 1340 Lathe Turning Center IS TESTED FOR QUALITY AND PERFORMANCE IN-HOUSE IN IRWINDALE, CA USA.

CNC MASTERS 1340 Lathe: Recommended for general turning, chamfering, facing, boring, inside thread and outside thread. Built-In Turn-Key CNC system for true 2 axis X and Z control with computer variable spindle encoder control and safety limit switches. X and Z axis ball screws with pre-loaded ballnuts and motors installed as direct drives. The user-friendly windows Master operating software is included with user’s manual. Standard 1340 lathe items also included: Motor Pulley, Backplate for Three-Jaw Chuck, Backplate for Four-Jaw Chuck, 3-Jaw Scroll Chuck, 4-Jaw Independent Chuck, Center Sleeve Bushing MT-5 to MT-3, Change gear for threading (needed for manual option threading only), Tool Post Wrench, 4 Way Tool Post, Steady Rest, Follow Rest, Faceplate 11.75″, Machine Stands with Center Kick Plate and Chip Pan. One Year Warranty. Life-long tech support for as long as company owns this equipment. Power requirements: 115vac for controller. 208, 220-240vac, single phase for spindle motor. Accessories include: Removable Sliding Splash Guard with Lever Locks, Wedge-Type Quick Tool Change Tool Post on machined T-Nut with 5 holders, Computer Control Coolant Pump with hose, container, and flex nozzle, speed, jogging, and micro-positioning.

$10,849.00

$10,849.00Add to Quote

CNC MASTERS 1340 Lathe: Recommended for general turning, chamfering, facing, boring, inside thread and outside thread. Built-In Turn-Key CNC system for true 2 axis X and Z control with computer variable spindle encoder control and safety limit switches. X and Z axis ball screws with pre-loaded ballnuts and motors installed as direct drives. The user-friendly windows Master operating software is included with user’s manual. Standard 1340 lathe items also included: Motor Pulley, Backplate for Three-Jaw Chuck, Backplate for Four-Jaw Chuck, 3-Jaw Scroll Chuck, 4-Jaw Independent Chuck, Center Sleeve Bushing MT-5 to MT-3, Change gear for threading (needed for manual option threading only), Tool Post Wrench, 4 Way Tool Post, Steady Rest, Follow Rest, Faceplate 11.75″, Machine Stands with Center Kick Plate and Chip Pan. One Year Warranty. Life-long tech support for as long as company owns this equipment. Power requirements: 115vac for controller. 208, 220-240vac, single phase for spindle motor.

$9,899.00

$9,899.00Add to Quote

CNC Accessories

Wedge-type Quick Tool Post with 5 holders Set. Quickly change out your cutters while retaining the cutter edge at the center of your stock. No more need to shimmy and properly align your cutters to the center of your stock with this Quick Change Tool Post. The kit comes to you with a block that you will need to machine into a custom T-Nut to fit the size of your T-Slot…..$395.00.

$395.00

$395.00Add to Quote

Sliding Splash Guard which can easily be removed or locked into place with two built-in levers. Keep debris and splash enclosed during your CNC lathe operation. 28″ long, and plenty of space for parts on a 13″ swing.

$354.00

$354.00Add to Quote

Computer Control Coolant Kit. Keep your cutters from quickly dulling out. Keep debris from welding on your cutters with coolant control. You can operate coolant on/off or through M-codes on the Master operating Software. This system comes to you with a pre-drilled hole and strainer mounted at the center of your chip pan. Also included: funnel, hoses, container, magnetic base with flex nozzles, and submersible pump

$235.00

$348.00Add to Quote

Software Packages

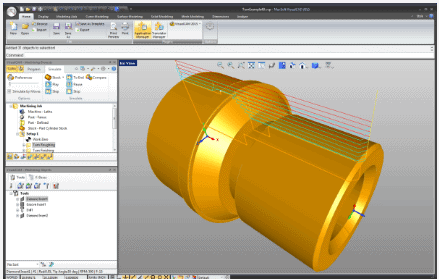

VisualCAD/CAM Software is ideal for the general machinist. This option gives you modeling, milling, and turning all into one software. This product is ideal for production machining (milling and lathe), rapid prototyping where ease of use and powerful toolpath generation methods are of paramount importance. Standard Version Includes:

- 2D & 3D Modeling, Mesh modeling

- 2 1/2 Axis Milling

- 3 Axis Milling

- Drilling

- TURN Module – 2 Axis Turning/Lathe programming module

- ART Module – Artistic Modeling (Raster to Vector conversion, Pictures to 3D geometry…)

- NEST Module – Parts Nesting (Rectangular and True-Shape Nesting)

- First Year Maintenance included with your purchase from CNC Masters — this includes “direct tech support by phone, online connection, and email,” tutorials, and updates. You can opt to keep the maintenance package for a nominal annual subscription fee after your first year. If you choose not to keep this maintenance package, you still keep the license to your software.

TBA

$1,400.00Add to Quote